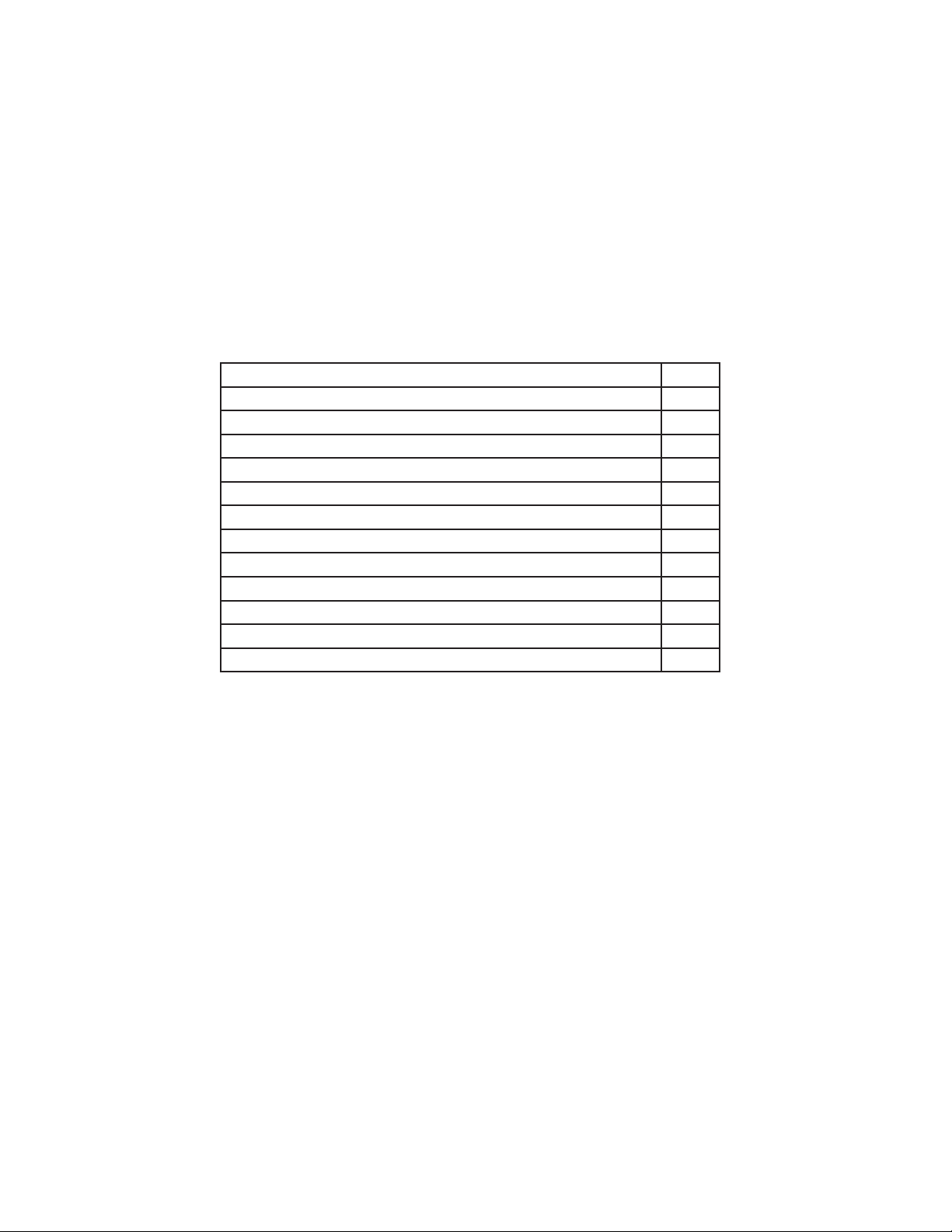

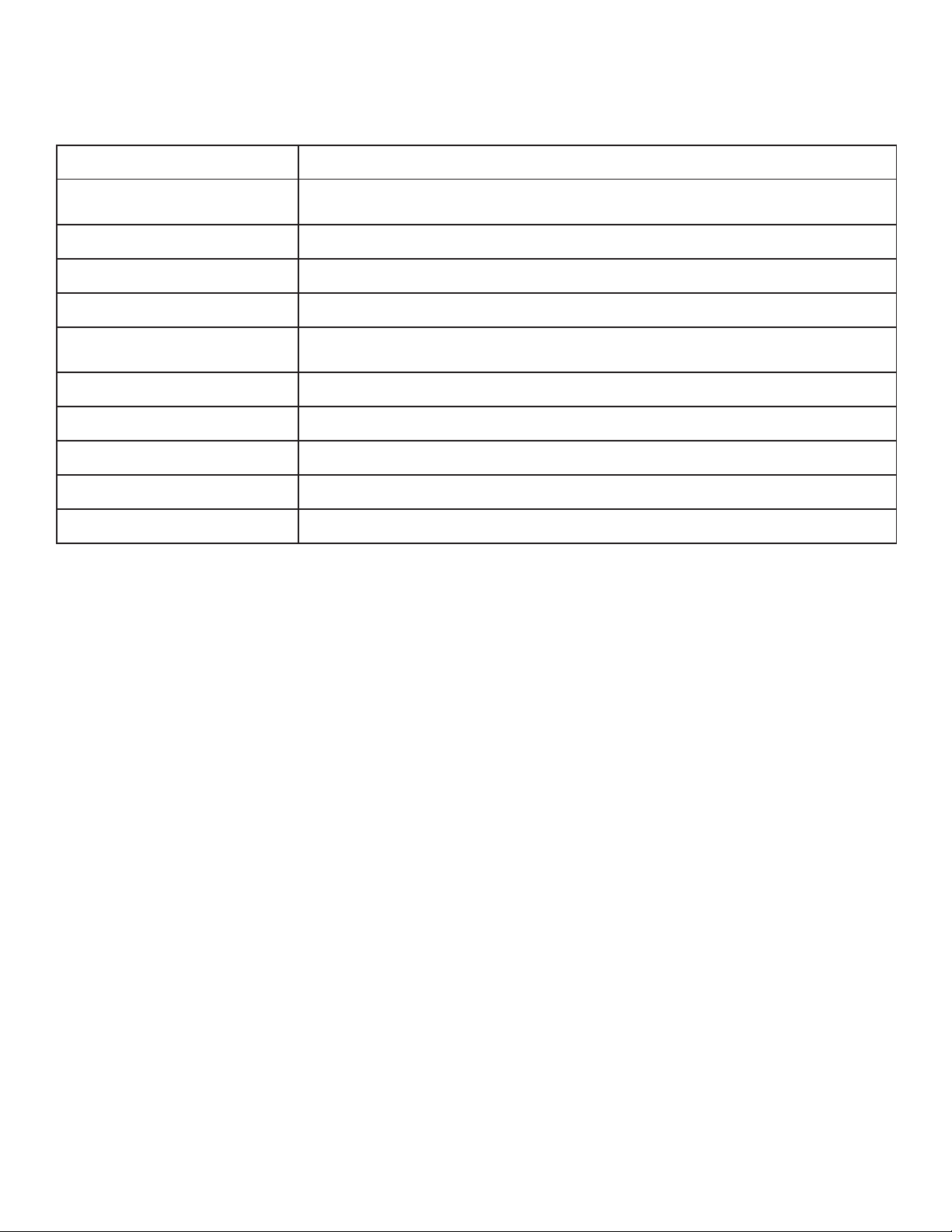

SPECIFICATIONS

1

Paper size: Letter, Half Sheet, Ledger

Recommended paper weight: 80 – 180 gsm

Note: 60 gsm paper can be processed using special guide strips (optional)

Speed: Up to 6,800/hr (FD 90), up to 7,080 (FD 95)

Max. feed table width: 13.8” (350mm)

Feed table capacity: Max. sheet stacking height: 1.18” (30mm)

Dimensions: Closed: 19.5” L x 14” W x 15” H

Fully extended: 43” L x 14” W x 15” H

Shipping dimensions: 21.5” L x 15.7” W x 16” H (545 x 400 x 405mm)

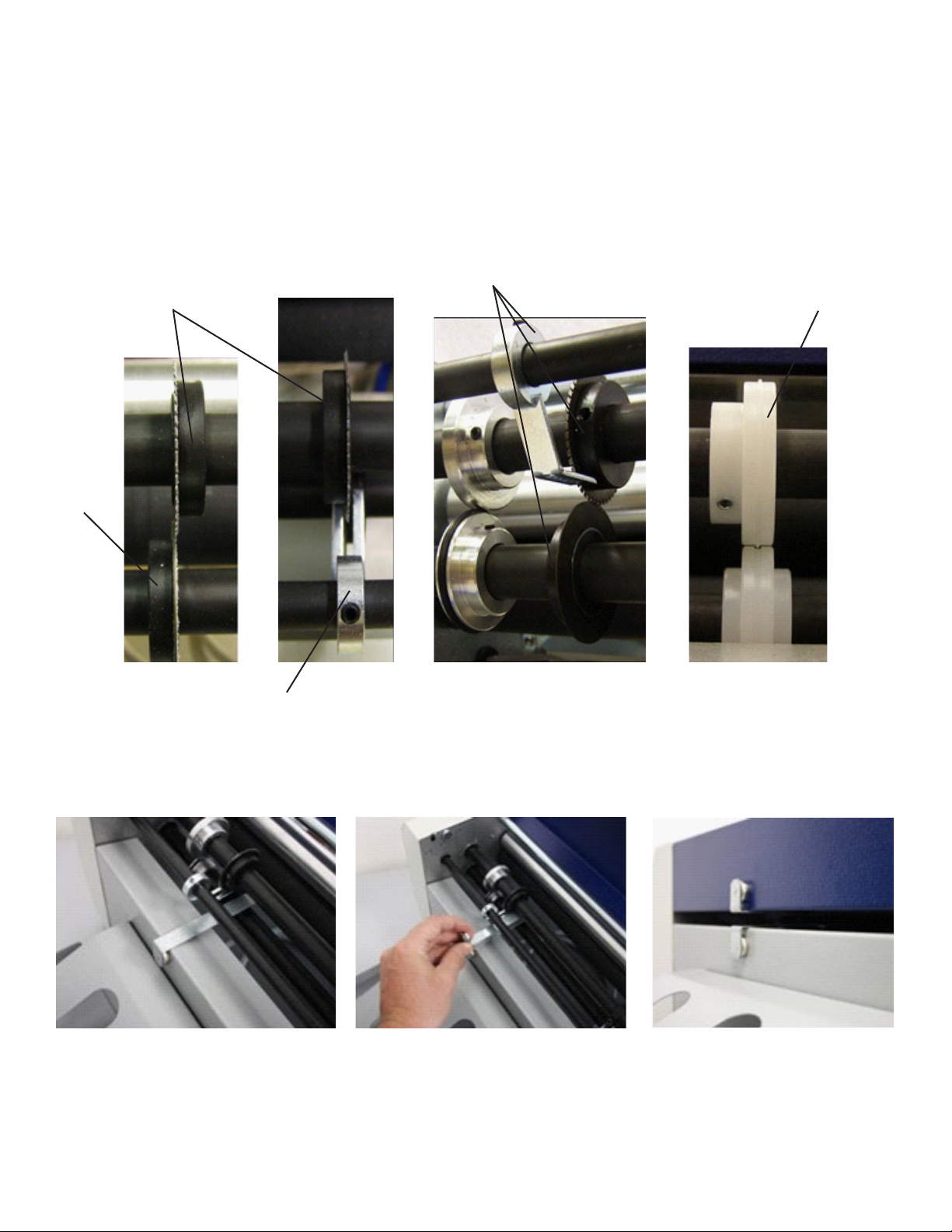

Perforating blade capacity: Up to 5 (includes 2 perforating tools and 1 creasing wheel)

Power: 110V / 60Hz (30W)

Weight: Net weight 41 lbs (18.5 kg)

Optional equipment: Microperforation knife (17tpi), guide strips to accommodate 60 gsm paper

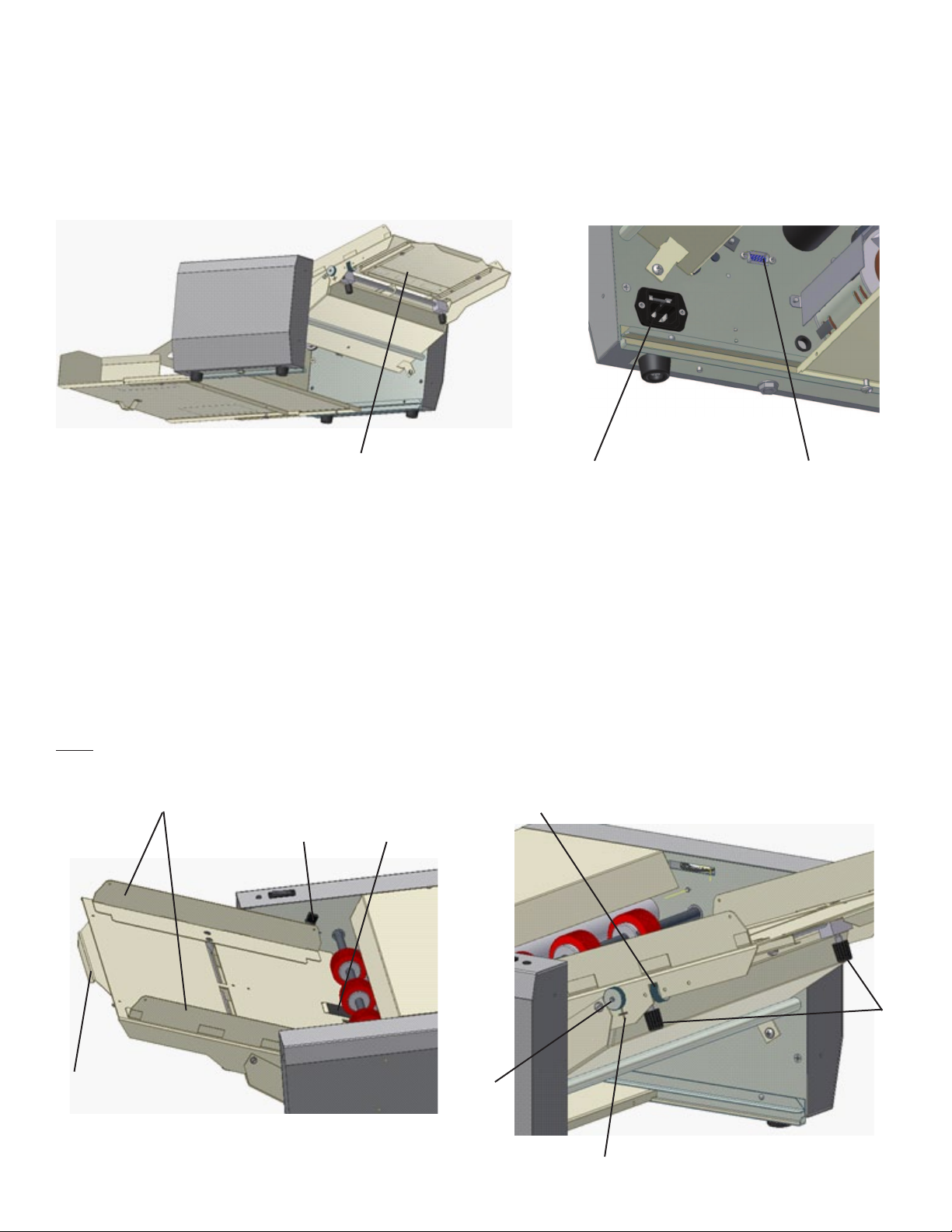

SAFETY PRECAUTIONS

• Read all instructions carefully before operating.

• TheFD90/FD95aredesignedtoperforatepaperonlywithspecicationsnotedabove.

• DO NOT use the FD 90 / FD 95 to perforate metal foil, tin sheets or similar material.

• Besureallcoversareinplaceandsecurebeforeoperation.

• The FD 90 / FD 95 should only be used indoors.

• If paper jams, the machine makes an unusual noise or is damaged, discontinue use immediately, switch off the power,

unplug and check the troubleshooting procedures.

• Only trained operators should use the machine.