3

WWW.FORNEYIND.COM

PERSONAL PRECAUTIONS

PREPARING TO CHARGE

1. Working in the vicinity of a lead-acid battery is

dangerous. Batteries generate explosive gases

during normal battery operation. For this reason,

it is of utmost importance that you follow the

instructions each time you use the charger.

2. To reduce the risk of a battery explosion, follow

these instructions and those published by the

battery manufacturer and the manufacturer of any

equipment you intend to use in the vicinity of the

battery. Review the cautionary markings on these

products and on the engine.

3. NEVER smoke or allow a spark or flame in the

vicinity of a battery or engine.

4. Be extra cautious to reduce the risk of dropping a

1. Consider having someone close enough by to come

to your aid when you work near a lead-acid battery.

2. Have plenty of fresh water and soap nearby in case

battery acid contacts your skin, clothing or eyes.

3. Wear complete eye and body protection, including

safety goggles and protective clothing. Avoid

touching your eyes while working near the battery.

4. If battery acid contacts your skin or clothing,

immediately wash the area with soap and water.

If acid enters your eye, immediately flood the eye

with cold running water for at least 10 minutes

and get medical attention right away.

5. If battery acid is accidentally swallowed, drink

milk, the whites of eggs or water. DO NOT induce

vomiting. Seek medical attention immediately.

6. If it is necessary to remove the battery from the

vehicle to charge it, always remove the grounded

terminal first. Make sure all of the accessories in

the vehicle are off to prevent arcing.

7. Be sure the area around the battery is well

ventilated while the battery is being charged.

8. Clean the battery terminals before charging the

metal tool onto the battery. It might spark or short-

circuit the battery or other electrical part that may

cause an explosion.

5. Use this charger for charging LEAD-ACID batteries

only. It is not intended to supply power to a low

voltage electrical system other than in a starter-

motor application. Do not use this battery charger

for charging dry-cell batteries that are commonly

used with home appliances. These batteries may

burst and cause injury to persons and damage to

property.

6. NEVER charge a frozen battery.

7. NEVER overcharge a battery.

battery. During cleaning, keep airborne corrosion

from coming into contact with your eyes, nose and

mouth. Use baking soda and water to neutralize

the battery acid and help eliminate airborne

corrosion. Do not touch your eyes, nose or mouth.

9. Add distilled water to each cell until the battery

acid reaches the level specified by the battery

manufacturer. Do not overfill. For a battery without

removable cell caps, such as valve regulated

lead acid batteries (VRLA), carefully follow the

manufacturer’s recharging instructions.

10. Read, understand and follow all instructions for

the charger, battery, vehicle and any equipment

used near the battery and charger. Study all of the

battery manufacturer’s specific precautions while

charging and recommended rates of charge.

11. Determine the voltage of the battery by referring to

the vehicle owner’s manual and make sure that the

output voltage selector switch is set to the correct

voltage. If the charger has an adjustable charge

rate, charge the battery in the lowest rate first.

12. Make sure that the charger cable clips make tight

connections.

CHARGER LOCATION

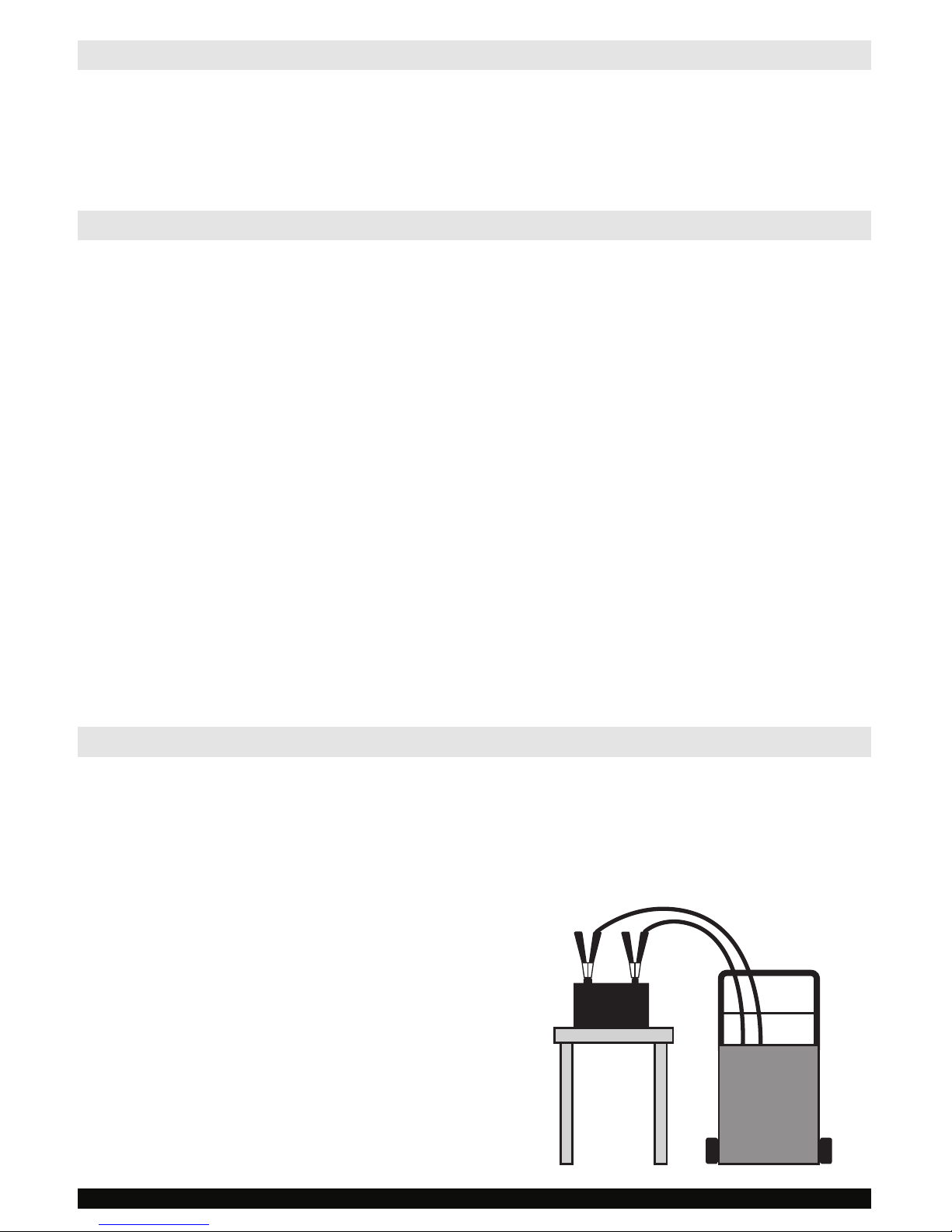

1. Locate the charger as far away from the battery

as the DC cables permit.

2. Never place the charger directly above the

battery being charged; gases from the battery

will corrode and damage the charger.

3. Do not set the battery on top of the charger.

4. Never allow battery acid to drip onto the charger

when reading the electrolyte specific gravity or

filling the battery.

5. Do not operate the charger in a closed-in area or

restrict the ventilation in any way.