Updated 6.11.2020 © Copyright 2020 Franklin Electricwww.franklin-controls.com |800.962.3787 | 310 Sequoia Parkway, Canby, Oregon 97013

indicates an imminently hazardous situation which, if not avoided, will

result in death or serious injury. This signal word is to be limited to the

most extreme situations.

indicates a potentially hazardous situation which, if not avoided, could

result in death or serious injury.

indicates a potentially hazardous situation which, if not avoided, may

result in minor or moderate injury. It may also be used to alert against

unsafe practices.

This is the safety alert symbol. Read and follow instructions carefully to

avoid a dangerous situation.

This symbol alerts the user to the presence of “dangerous voltage”

inside the product that might cause harm or electrical shock.

DANGER

WARNING

CAUTION

Safety Instructions

Equipment starts automatically. Lockout/tagout before servicing.

As with all electrical products, read manual thoroughly. Only qualified,

expert personnel should perform maintenance and installation. Contact the

nearest authorized service facility for examination, repair, or adjustment.

Do not disassemble or repair unit unless described in this manual; death

or injury to electrical shock or fire hazard may result. Specifications and

manual data subject to change. Consult factory for additional information.

DANGER

CAUTION

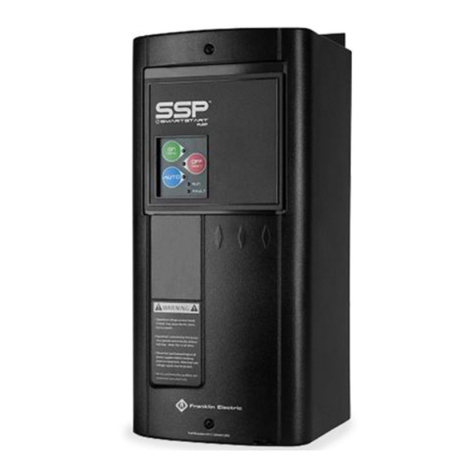

L1 L2/N

T1 T2

M

Voltage Input

Auto Run

Fault

Status

Output

Dry Input

Auto Run

Input

12-120V

Input

Main Power Wiring

Wire main power input and output to the appropriate 12AWG wire leads utilizing

properly sized wire nuts. Use only copper conductors rated at least 60°C.

Maintain proper clearances and verify that no possibility of an electrical short

exists between the power conductors or enclosure. Ensure that wires are not

under stress and all insulation is intact.

Low Voltage Wiring

Automation system control wiring should be run in a separate conduit. The

control terminals accept 26~14AWG wire torqued to 3.5 in-lb.

Installation

FAILURE TO FOLLOW THESE INSTRUCTIONS MAY RESULT IN DEATH OR

SERIOUS INJURY

Mounting

Mount the starter on a minimum 14 cu-in single gang junction box. To access

mounting holes, slide upper and lower covers to the open position.

(See Figure 1)

Using provided mounting screws (6-32 x 7/8”), attach starter housing to junction

box (once appropriate wiring has been completed).

•

materials. Contact arcing can induce explosion or fire.

gnitnuomefaS.ylnosnoitacoletairporppa)1AMEN(1epyTLUniretratsllatsnI•

requires a dry, protected environment.

• The BAS-1P is rated for maximum ambient temperature of 40°C

.erusolcneretneotnoitallatsnimorfsirbedrosgnivahslatemynawollatonoD•

WARNING

Figure 1

HAZARDOUS VOLTAGE

.tnempiuqegnicivresrognillatsnierofebrewopllatuokcoldnatcennocsiD•

ecivresotroirpsecruosrewopelpitlumtuognikcoleriuqeryamtnempiuqesihT•

dnalacirtcelelanoitan&lacolelbacilppallahtiwecnadroccanieriwdnallatsnI•

construction codes

Installation & Operation Guide

LIT-12013012

Thank you for purchasing the Franklin Electric

Single Phase Building Automation Starter!

Please read this manual thoroughly to ensure

safe installation and proper operation.

Precautions

To prevent injury and property damage, follow these instructions.

Failure to adhere to installation/operation procedures and all applicable

codes may result in hazards as indicated by warning

codes outlined below: