Tabel of Contents

1. Introduction................................................................................................................................................................................ 1

2. The manual's target group ......................................................................................................................................................... 1

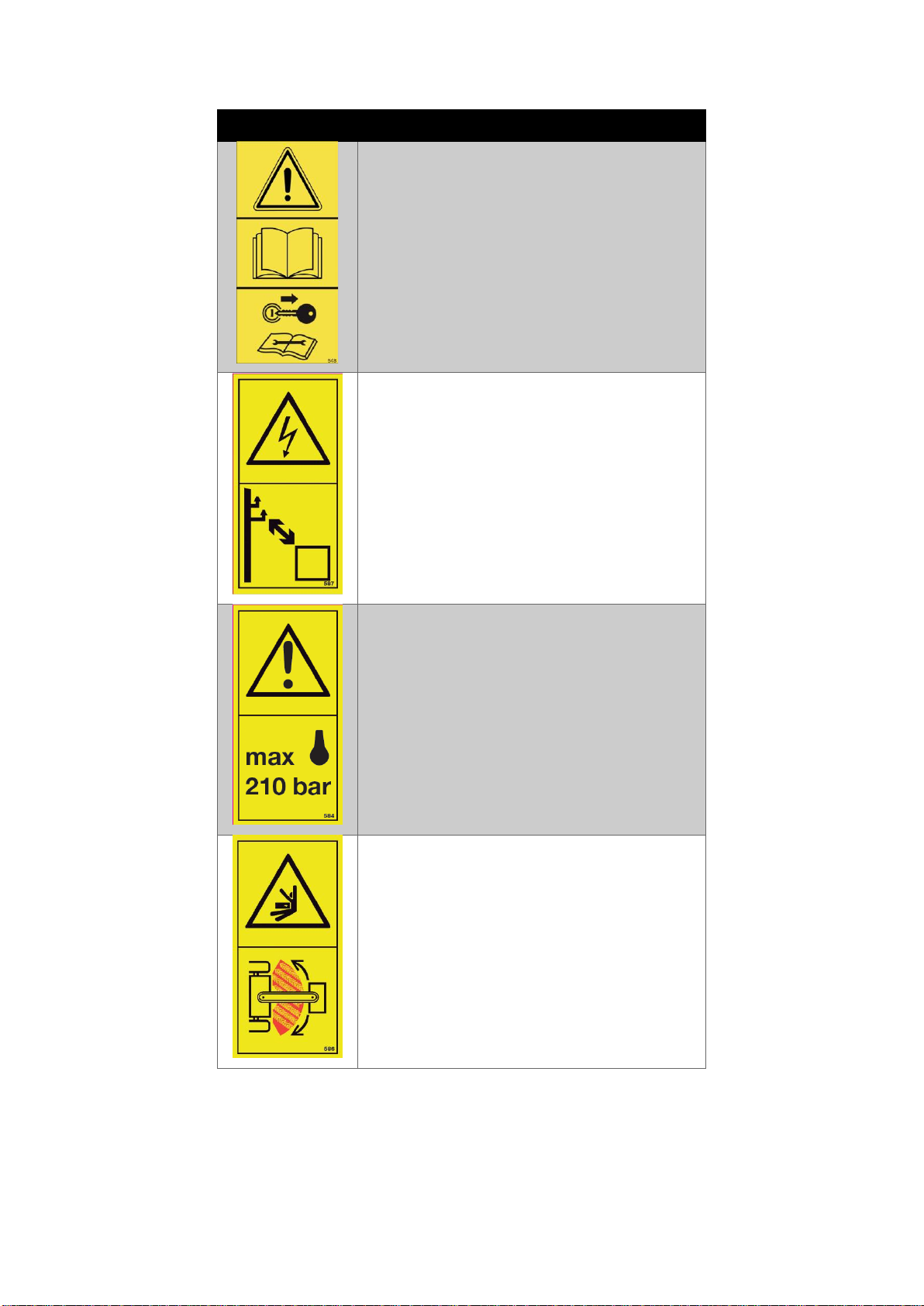

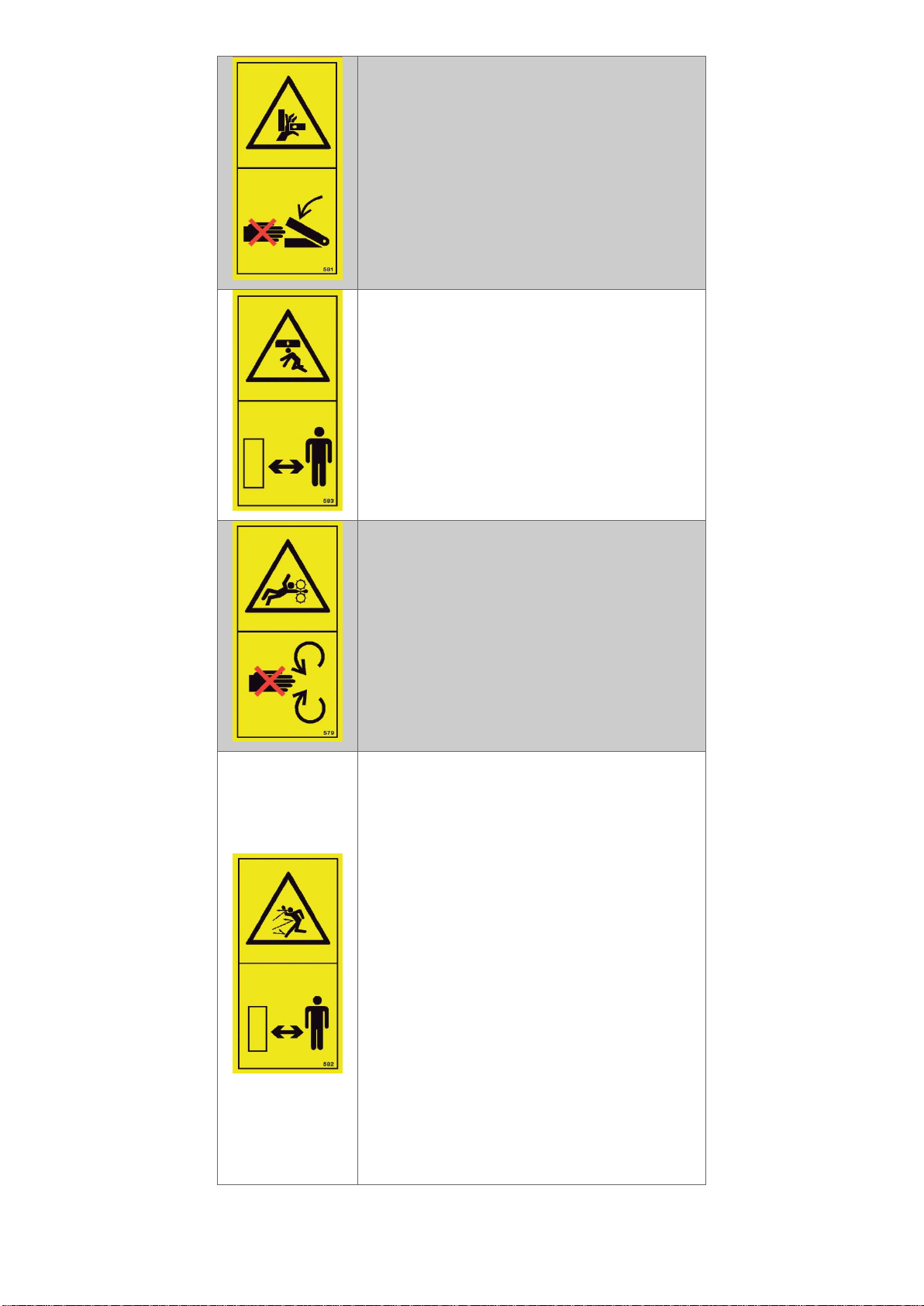

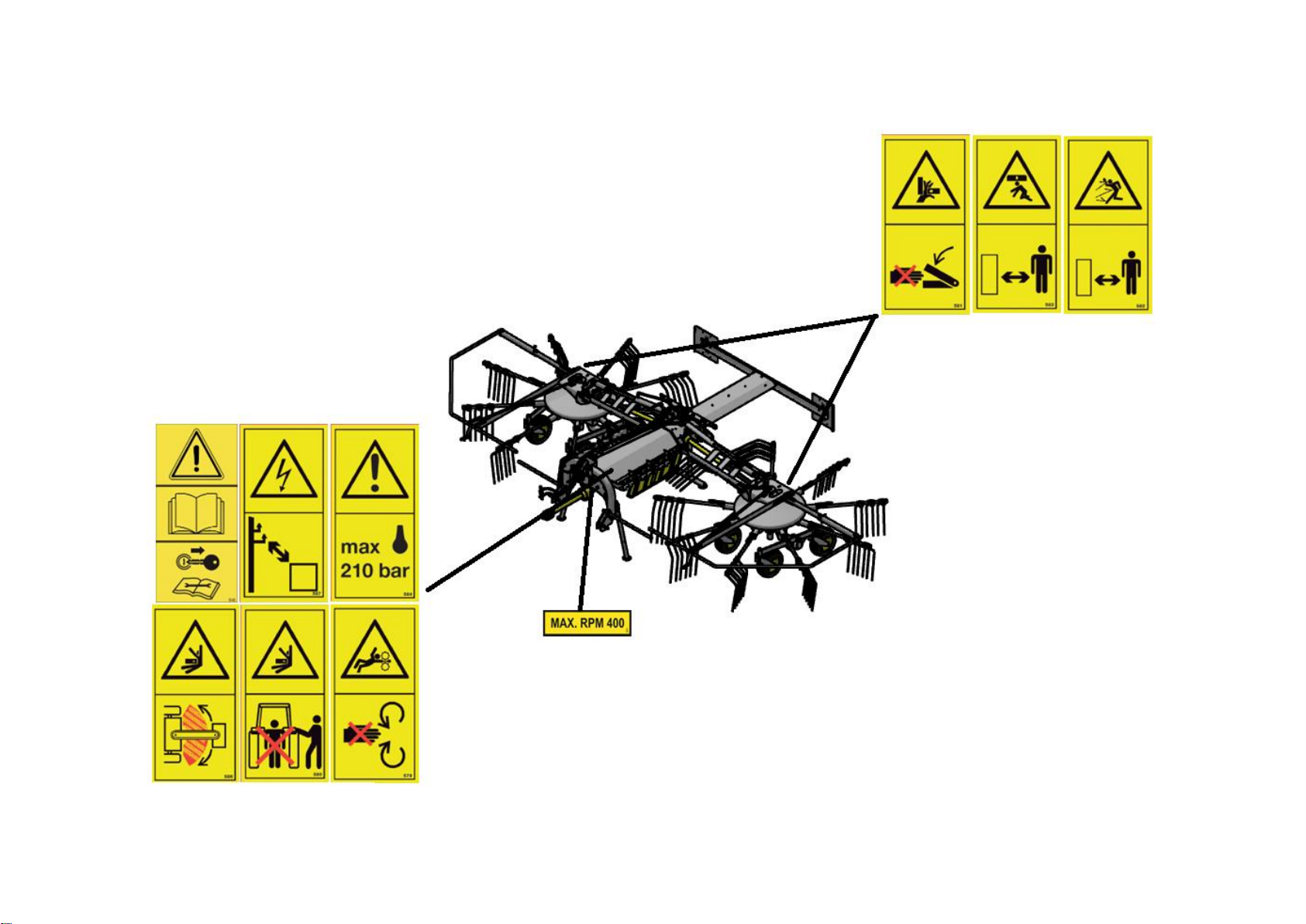

3. Symbols ...................................................................................................................................................................................... 2

4. Placement of symbols................................................................................................................................................................. 5

5. Technical data ............................................................................................................................................................................ 6

6. Safety instructions ...................................................................................................................................................................... 7

6.1. Intended use....................................................................................................................................................................... 7

6.2. Who is allowed to drive the machine?............................................................................................................................... 7

6.3. The owner's responsibility.................................................................................................................................................. 7

6.4. Connecting the tool............................................................................................................................................................ 7

6.5. Disconnecting the tool ....................................................................................................................................................... 7

6.6. PTO axles ............................................................................................................................................................................ 8

6.7. Driving in the transport position ........................................................................................................................................ 8

6.8. Driving in operation............................................................................................................................................................ 8

6.9. Maintenance ...................................................................................................................................................................... 9

6.10. Hydraulics......................................................................................................................................................................... 9

7. Delivery and assembly of the machine..................................................................................................................................... 10

7.1. Delivery............................................................................................................................................................................. 10

7.2. The length of the PTO axle ............................................................................................................................................... 10

8. Preparing the machine for operation ....................................................................................................................................... 11

8.1. Connecting to the tractor................................................................................................................................................. 11

8.2. Connecting hydraulic hoses to the tractor ....................................................................................................................... 11

8.3. PTO axle connection......................................................................................................................................................... 11

8.4. Adjusting the inclination of the main frame..................................................................................................................... 12

8.5. Adjusting the rotor height ................................................................................................................................................ 12

8.6. Adjusting the cam............................................................................................................................................................. 12

8.7. Attaching and detaching the raking arms ........................................................................................................................ 13

8.8. Adjusting the tractor's hydraulic flow .............................................................................................................................. 13

8.9. Nose wheel adjustment (optional extra).......................................................................................................................... 13

9. Operating the tool .................................................................................................................................................................... 14

9.1. Unfolding the tool. ........................................................................................................................................................... 14

9.2. Unfolding the tool with a hydraulic lock (Optional extra)................................................................................................ 14

9.3. Driving with the tool......................................................................................................................................................... 14

9.4. Turning around in a headland .......................................................................................................................................... 15

9.5. Folding the tool ................................................................................................................................................................ 15

10. Maintenance and repairs ....................................................................................................................................................... 16

10.1. Lubrication...................................................................................................................................................................... 16

10.2. Tightening bolts.............................................................................................................................................................. 17

10.3. Replacing spring teeth.................................................................................................................................................... 18

10.4. Replacing nylon wheels .................................................................................................................................................. 18

10.5. Replacing nylon bearings................................................................................................................................................ 19

10.6. Level check and oil change of the T-gear ....................................................................................................................... 19

10.7. Tyres ............................................................................................................................................................................... 20

10.8. Hydraulic hoses .............................................................................................................................................................. 20

10.9. Cleaning.......................................................................................................................................................................... 20

10.10. Storage ......................................................................................................................................................................... 20

11. Optional extras ....................................................................................................................................................................... 22

11.1. Nose wheel..................................................................................................................................................................... 22

11.2. Hydraulic lock ................................................................................................................................................................. 22

12. Troubleshooting ..................................................................................................................................................................... 23

13. Disposal .................................................................................................................................................................................. 26

13.1. Metal .............................................................................................................................................................................. 26