FR100L&FR200L For Wire drawing machine

- 3 -

Chapter 1 Product Information

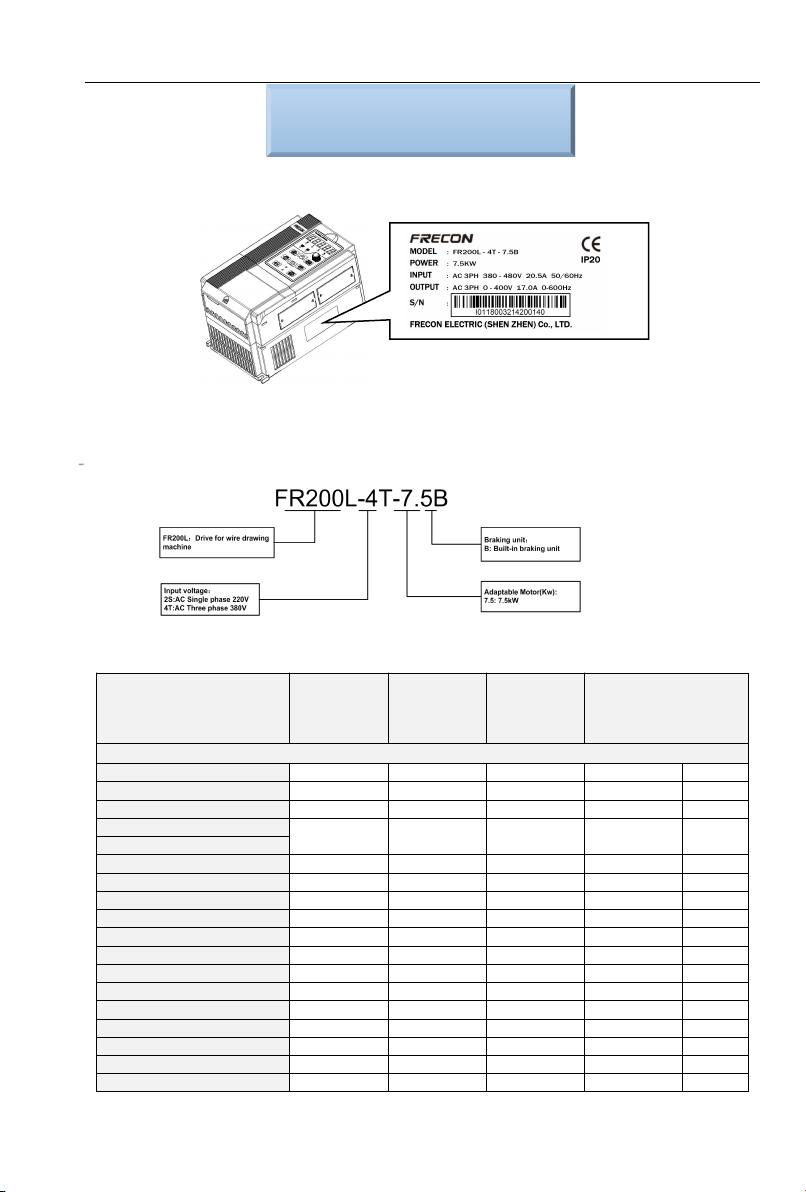

1.1 Nameplate information

Fig. 1-1 Nameplate

Model Instruction

Model numbers on name plate consist of numbers, symbols, and letters, to express its respective

series, suitable power type, power level and other information.

Fig 1-2 Model Explanation

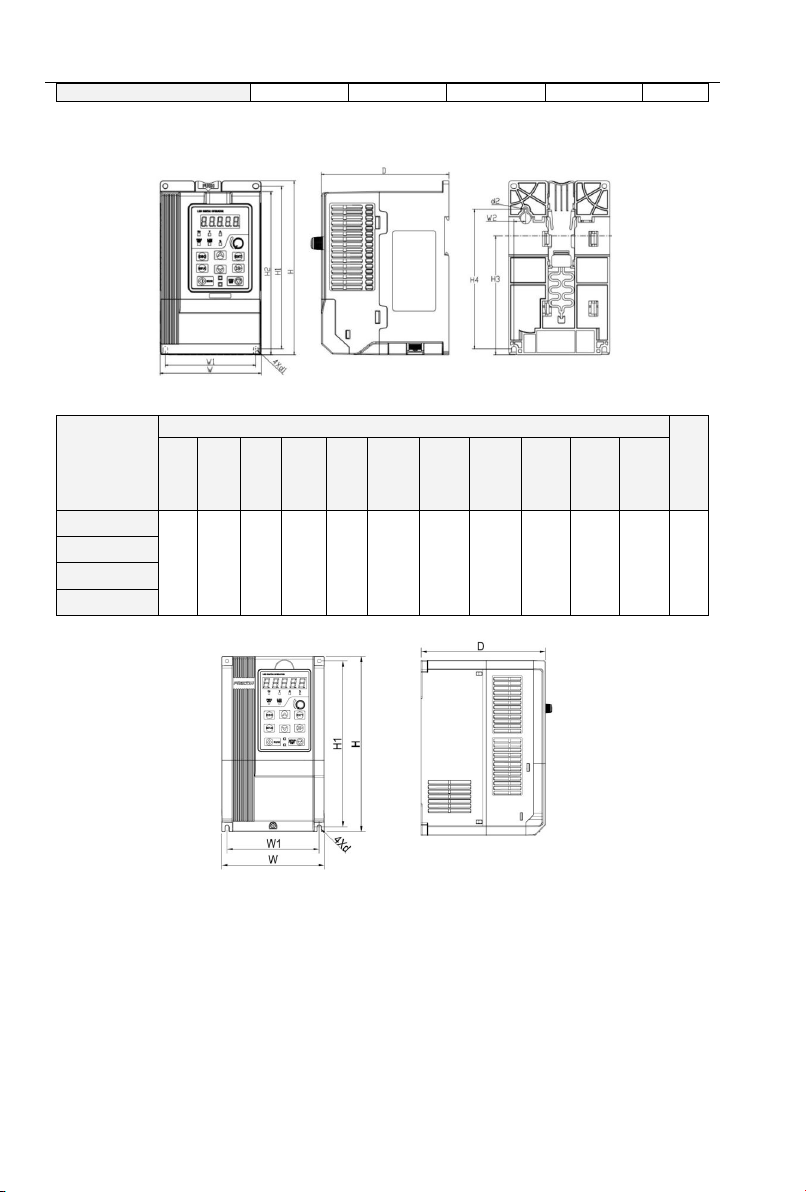

1.2 FR100&FR200L Special Purpose Drive Model Selection

Model No. Power

capacity

KVA

Rated

Input

current

A

Rated

output

current

A

Applicable motor

kW HP

3-Phase:380V,50/60Hz Range:-15%~+30%

FR100L-4T-0.7B 1.5 3.4 2.5 0.75 1

FR100L-4T-1.5B 3 5.0 4.2 1.5 2

FR100L-4T-2.2B 4 5.8 5.5 2.2 3

FR100L-4T-4.0B 6 11 9.5 3.7、4 5

FR200L-4T-4.0B

FR200L-4T-5.5B 8.9 14.6 13 5.5 7.5

FR200L-4T-7.5B 11 20.5 17 7.5 10

FR200L-4T-011B 17 26 25 11 15

FR200L-4T-015B 21 35 32 15 20

FR200L-4T-018B 24 38.5 37 18.5 25

FR200L-4T-022B 30 46.5 45 22 30

FR200L-4T-030B 40 62 60 30 40

FR200L-4T-037 57 76 75 37 50

FR200L-4T-045 69 92 91 45 60

FR200L-4T-055 85 113 112 55 70

FR200L-4T-075 114 157 150 75 100

FR200L-4T-090 134 160* 176 90 125

FR200L-4T-110 160 190* 210 110 150