FR150A Series Multifunctional Compact Inverter

- 2 -

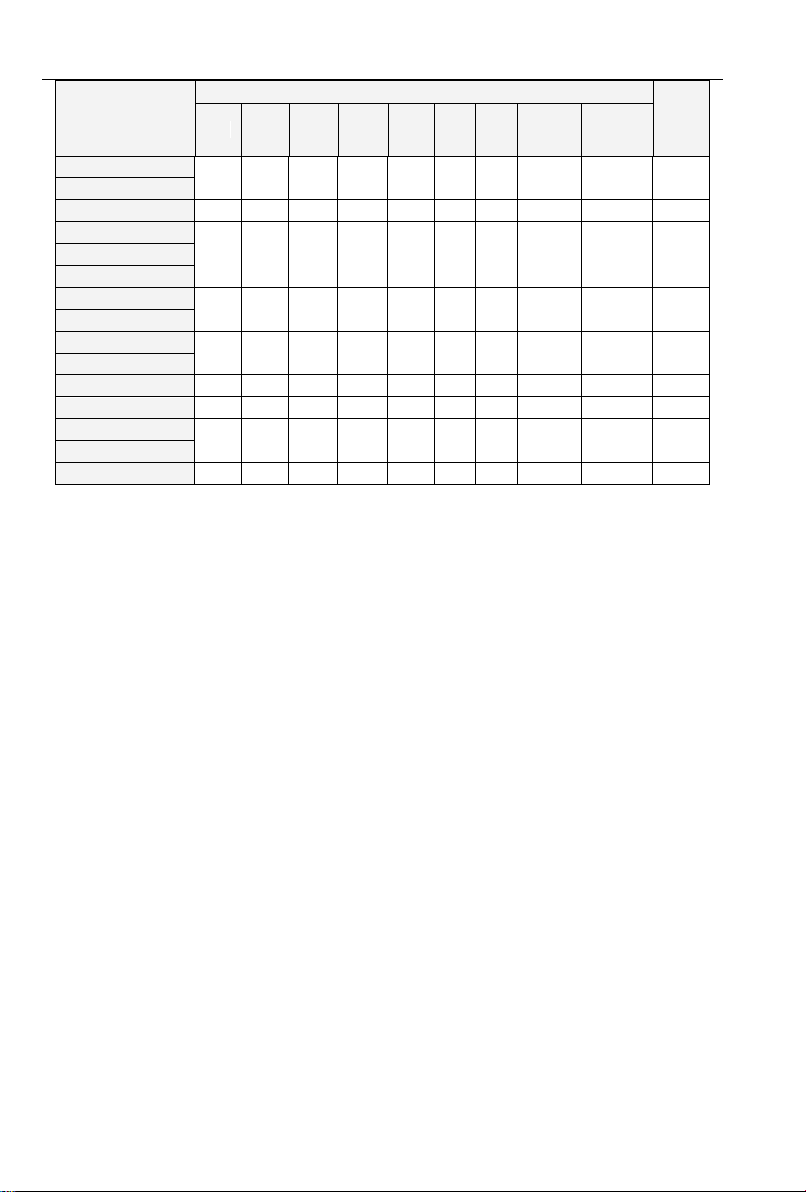

TABLE OF CONTENTS

PREFACE ....................................................................................................................................- 1 -

TABLE OF CONTENTS................................................................................................................- 2 -

CHAPTER 1 PRODUCT INFORMATION......................................................................................- 3 -

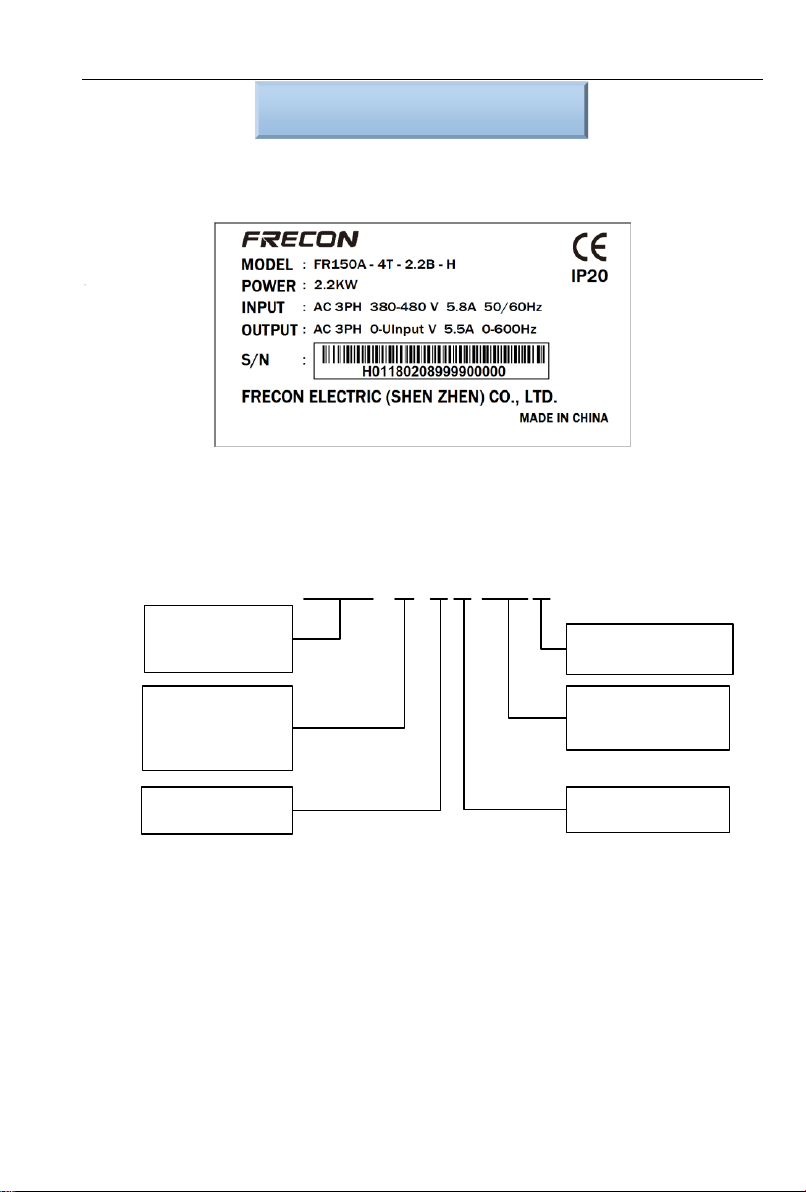

1.1 NAMEPLATE INFORMATION .....................................................................................................- 3-

1.2 INFORMATION OF FR150APRODUCT MODEL........................................................................... - 4-

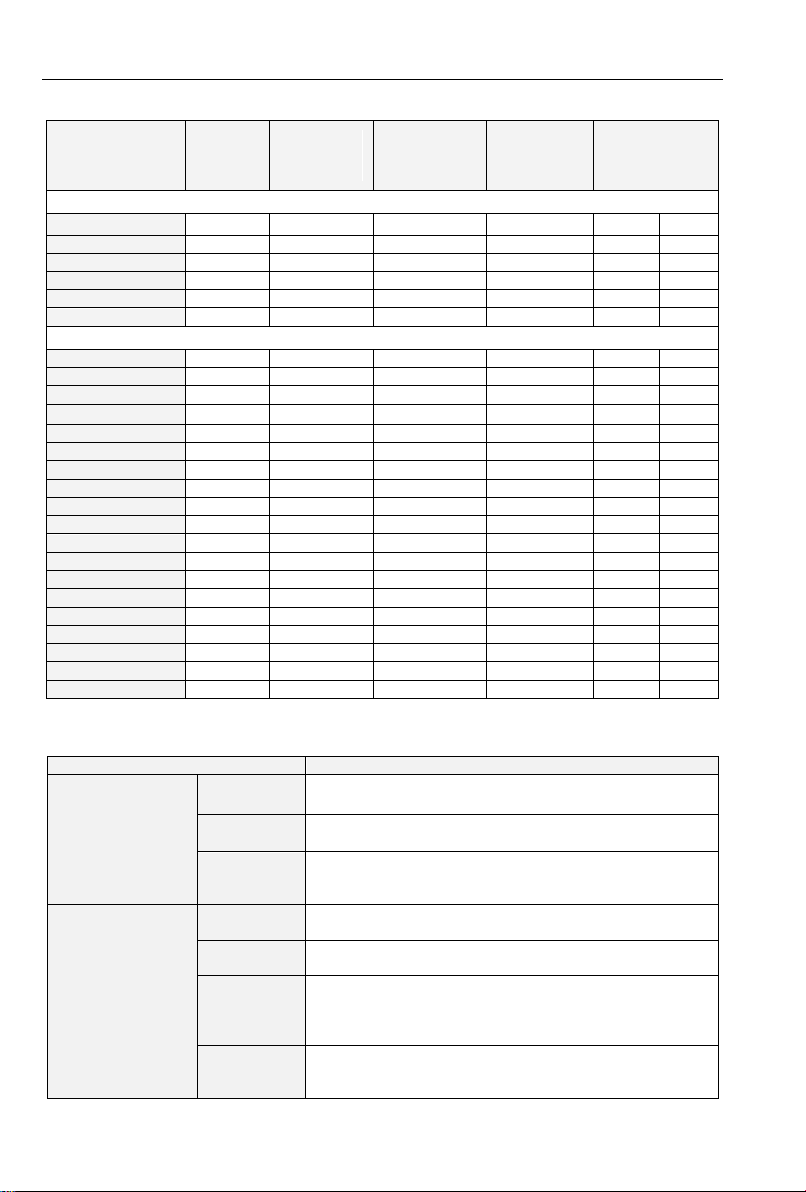

1.3 TECHNICAL FEATURES OF FR150A.........................................................................................- 4-

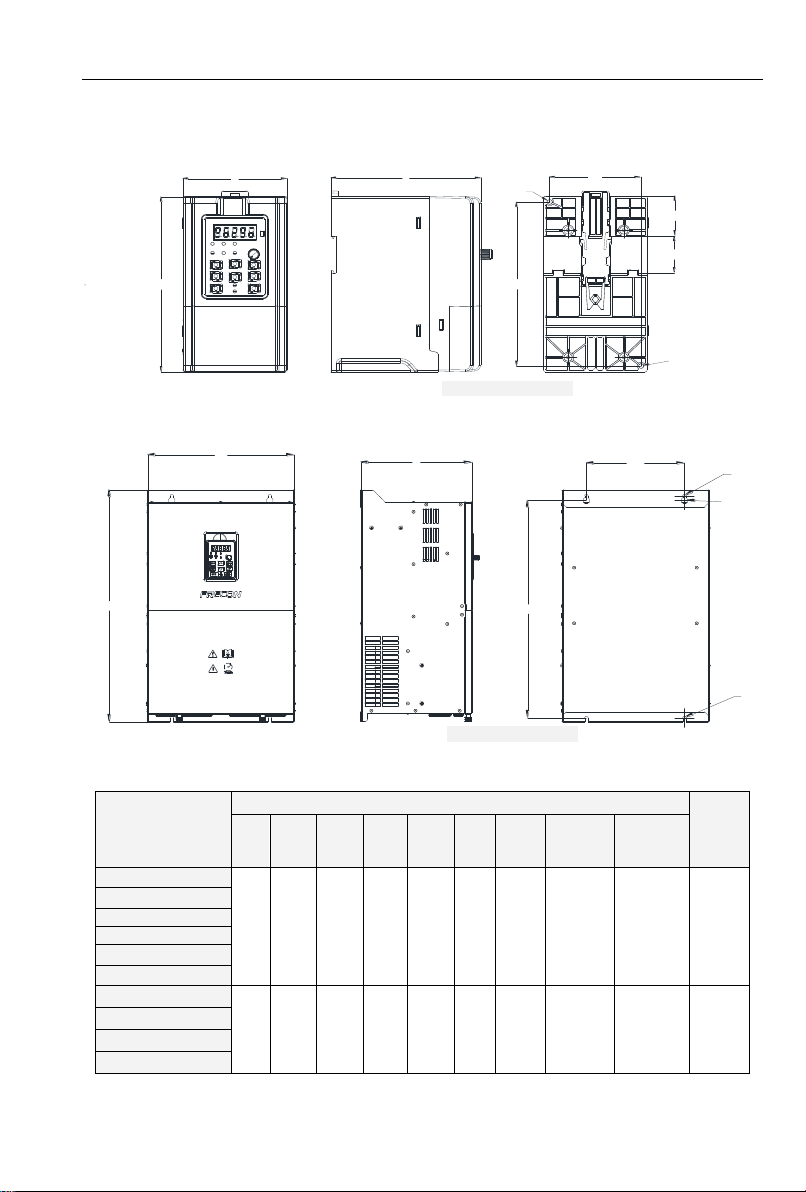

1.3 CONFIGURATION,MOUNTING DIMENSIONS AND WEIGHT............................................................- 7-

CHAPTER 2 WIRING AND TERMINALS......................................................................................- 9 -

2.1WIRING WAY.........................................................................................................................- 9-

2.2TERMINAL CONFIGURATION.................................................................................................. - 10 -

CHAPTER 3 OPERATION AND DISPLAY..................................................................................- 17 -

3.1 INTRODUCTION OF KEYPAD .................................................................................................. - 17 -

3.2VIEWING AND MODIFYING FUNCTION CODES.......................................................................... - 19 -

3.3 VIEWING STATUS PARAMETERS ............................................................................................- 20 -

3.4 MOTOR AUTO-TUNING.........................................................................................................- 20 -

3.5 PASSWORD SETTING........................................................................................................... - 20 -

3.6 KEYPAD LOCK ....................................................................................................................- 20 -

3.7 SHORTCUT MENUS FUNCTION CODE DESCRIPTION .................................................................. - 20 -

CHAPTER 4 LIST OF PARAMETER..........................................................................................- 22 -

4.1 FIVE LED (DIGITAL)DISPLAY INDICATORS............................................................................... - 23 -

4.2 STANDARD FUNCTION PARAMETERS .....................................................................................- 23 -

4.3 PULSE FEEDBACK...............................................................................................................- 48 -

CHAPTER 5 MAINTENANCE AND TROUBLESHOOTING........................................................- 49 -

APPENDIX A: MODBUS COMMUNICATION PROTOCOL ........................................................- 53 -

APPENDIX B: BRAKING RESISTOR.........................................................................................- 59 -