FR500A&FR510A Series Vector Control Inverter

- 6 -

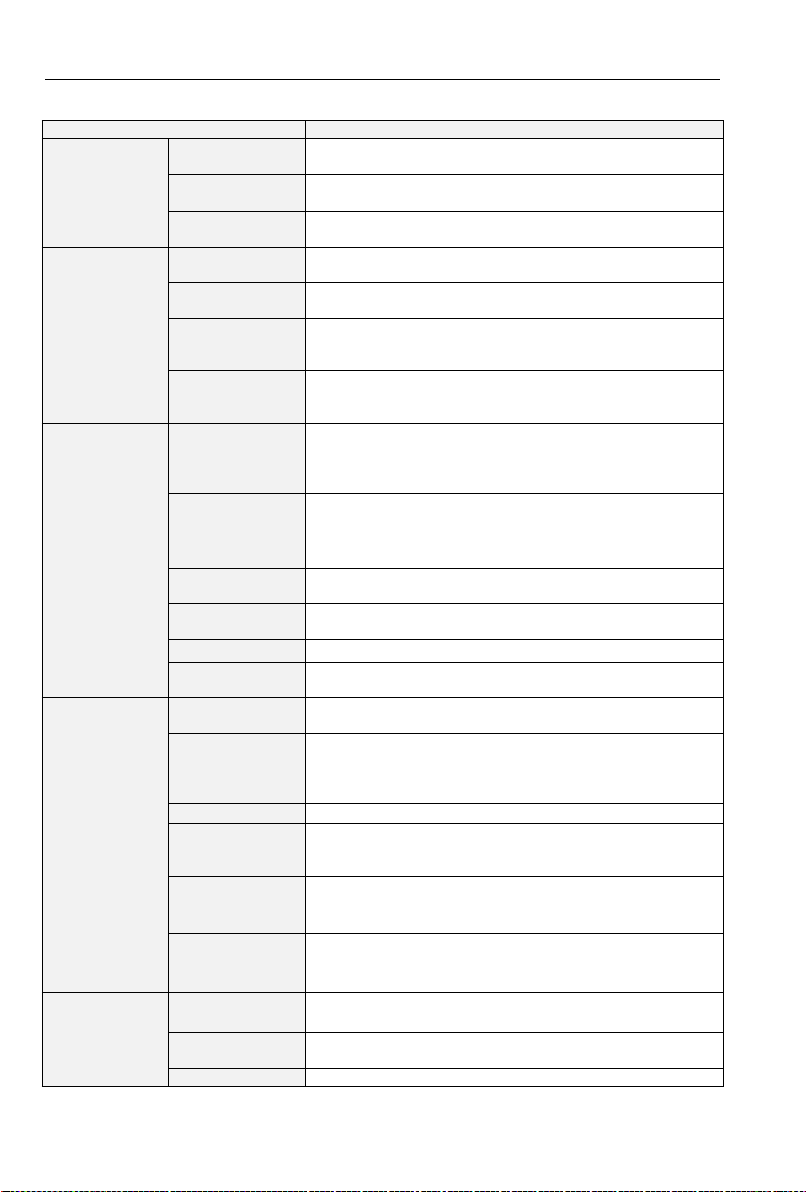

1.2 Precautions

1.2.1 Motor Insulation Inspection

When the motor is used for the first time or when the motor is reused after being kept, or when

periodical inspection is performed, insulation inspection shall be conducted with motor so as to avoid

damaging the inverter because of the insulation failure of the motor windings. The motor wires must be

disconnected from the inverter during the insulation inspection. It is recommended to use the 500V

mega meter, and the insulating resistance measured shall be 5MΩ at least.

1.2.2 Motor Thermal Protection

If the motor rating does not match that of the inverter, especially when the rated power of the

inverter is higher than that of the motor, adjust motor protection parameters in the inverter or install

thermal relay to protect motor.

1.2.3 Operating with the Frequency Higher than Grid Power Frequency

Output frequency of FR510A is 0.00Hz~600.00Hz. If FR510A is required to operate above

50.00Hz, please take the endurance of mechanical devices into consideration.

1.2.4 Mechanical Vibrations

Inverter may encounter mechanical resonance point of the load device at certain output

frequencies which can be avoided by setting the skip frequency parameters of the inverter.

1.2.5 Motor Heat and Noise

Since output voltage of inverter is PWM wave and contains a certain amount of harmonics, so

that the temperature, noise and vibration of the motor will be higher than those when the inverter runs

at grid power frequency.

1.2.6 Voltage-sensitive device or capacitor on output side of the AC drive

Do not install the capacitor for improving power factor or lightning protection voltage-sensitive

resistor on the output side of the AC drive because the output of the AC drive is PWM wave.

Otherwise, the AC drive may suffer transient overcurrent or even be damaged.

1.2.7 Contactor at the I/O terminal of the AC drive

When a contactor is installed between the input side of the AC drive and the power supply, the AC

drive must not be started or stopped by switching the contactor on or off. If the AC drive has to be

operated by the contactor, ensure that the time interval between switching is at least one hour since

frequent charge and discharge will shorten the service life of the capacitor inside the AC drive.

When a contactor is installed between the output side of the AC drive and the motor, do not turn

off the contactor when the AC drive is active. Otherwise, modules inside the AC drive may be

damaged.

1.2.8 Applied with the Rated Voltage

Apply FR510A with the rated voltage. Failure to comply will damage inverter. If required, take a

transformer to boost or step-down voltage.

1.2.9 Do Not Apply a 3-Phase Input Inverter to 2-Phase Input Applications

Do not apply a 3-phase input FR inverter to 2-phase input applications. Otherwise, it will result in

faults or damage inverter.

1.2.10 Lightning Protection

FR510A has integrated lightning over-current protection device which has certain

self-protection capacity against the lightning. Additional protection devices have to be installed

between inverter and power supply in the area where lightning occurs frequently.

1.2.11 Altitude De-rating

In places where the altitude is above 1000 m and the cooling effect reduces due to thin air, it is

necessary to de-rate the AC drive. Contact FRECON for technical support.

1.2.12 some special usages

If wiring that is not described in this manual such as common DC bus is applied, contact the agent

or FRECON for technical support.

1.2.13 Cautions for Inverter Disposal

The electrolytic capacitors on the main circuit and PCBA may explode when they are burnt.

Emission of toxic gas may be generated when the plastic parts are burnt. Please dispose inverter as

industrial wastes.

1.2.14 Adaptable Motor

The standard adaptable motor is adaptable four-pole squirrel-cage asynchronous induction motor

or PMSM. For other types of motor, select a proper AC drive according to the rated motor current.

The cooling fan and rotor shaft of non-variable-frequency motor are coaxial, which results in

reduced cooling effect when the rotational speed declines. If variable speed is required, add a more

powerful fan or replace it with variable-frequency motor in applications where the motor overheats