FR200H Special Purpose Inverters for Multi-pumps Constant Pressure Water Supply

- 7 -

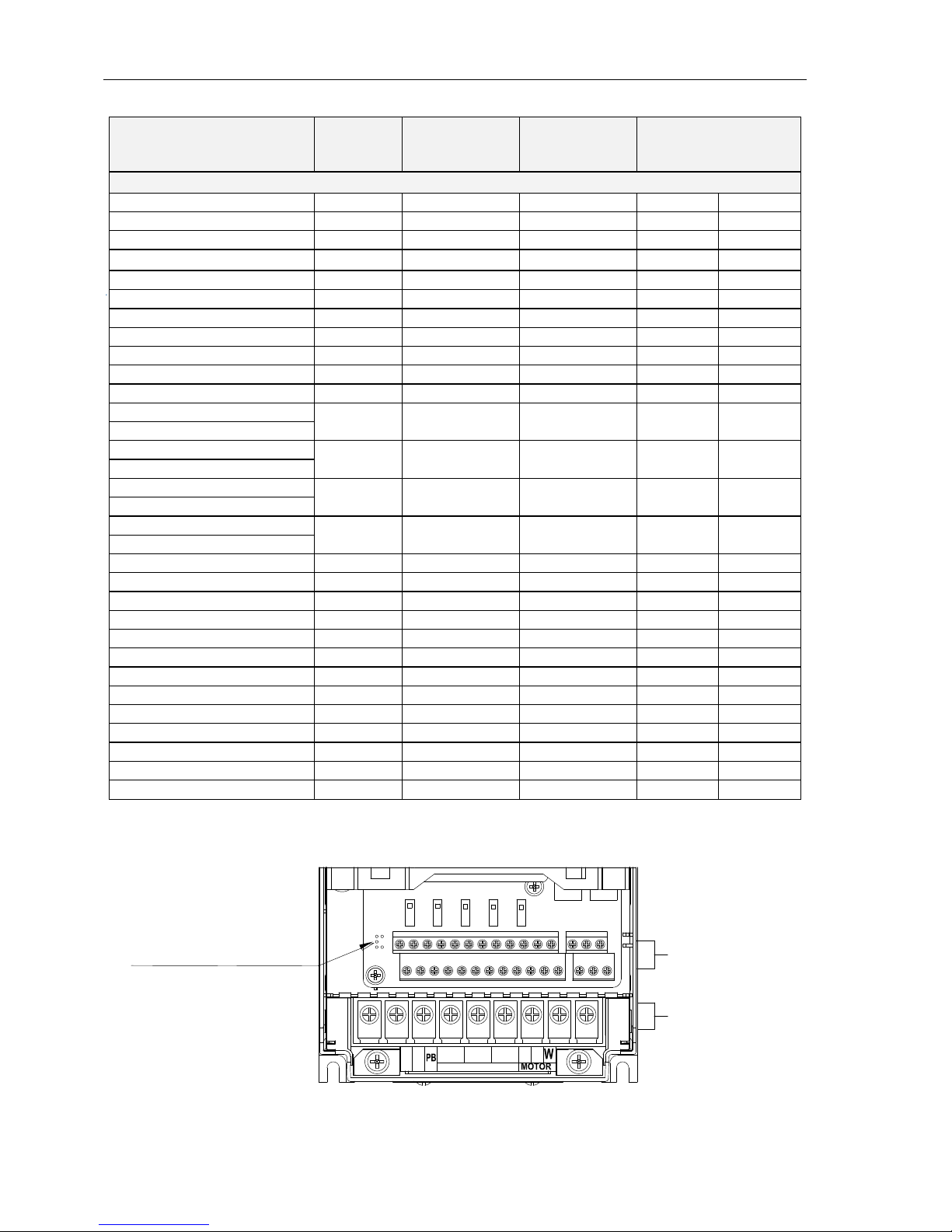

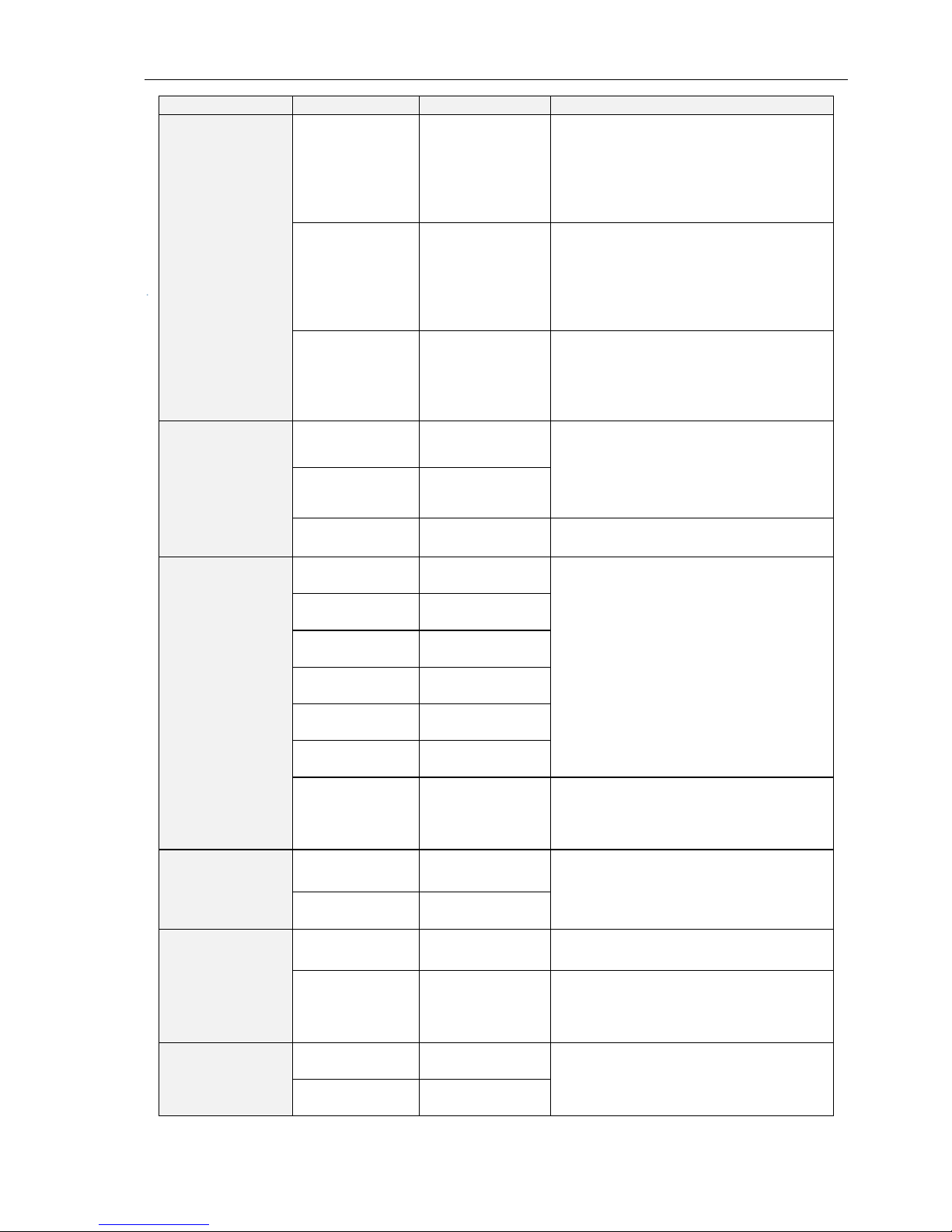

Table 1-3 FR200H Description of control circuit terminals

External +10 V

power supply

Provide +10 V power supply to

external unit.

Generally, it provides power supply to

externalpotentiometer with resistance

range of 1–5 kΩ.

Maximum output current: 10 mA

External +24V

power

supply Applying

to Overvoltage

Category II

circuit

Provide +24 V power supply to

external unit.

Generally, it provides power supply to

DI/Do terminals and external sensors.

Maximum output current: 200 mA

Input terminal

of

external power

supply

Connect to +24 V by default.

When DI1-DI7 need to be driven by

externalsignal, PLC needs to be

connected to externalpower supply

and be disconnected from +24 V.

Input voltage range: DC 0~10V/0~

20mA,decided by toggle switches

AI1、AI2 on the control board

Impedance: 250 kΩ (voltage input),

250 Ω (current input)

Input Voltage Range: DC -10~+10V

Input impedance: 250kΩ

Maximum input frequency: 200Hz

Impedance: 2.4kΩ

Voltage range for level input: 9V~

30V

Switch input

terminals 7 OR

High-speed

pulse input

Besides features of DI1–DI6, it can be

used for high-speed pulse input.

Maximum input frequency: 100 kHz

Output voltage range: DC 0~10V/0~

20mA,decided by toggle switches

AO1、AO2 on the control board

Impedance requirements≥10kΩ

Voltage range: 0~24V

Current range: 0~50mA

Open collector

output 2 OR

High-speed

pulse output

Besides features of Y1, it can be used

forHigh-speed pulse output channels.

The maximum output frequency:

100kHz

Contact driving capacity:

AC250V,3A,COSØ=0.4.

DC 30V,1A