FR200F series Special Purpose Inverter

- 8 -

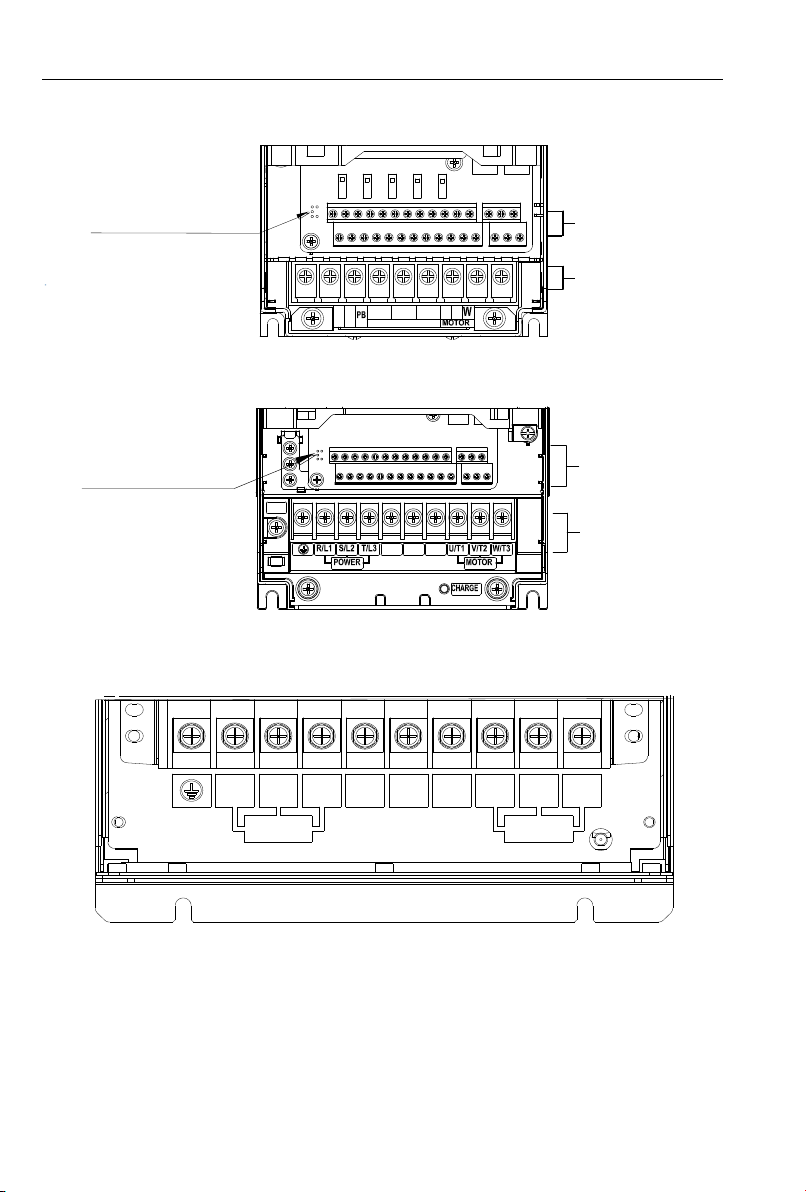

R/L1

U/T1 V/T2

(+)

(-)

POWER

MOTOR

S/L2 T/L3

P

POWER

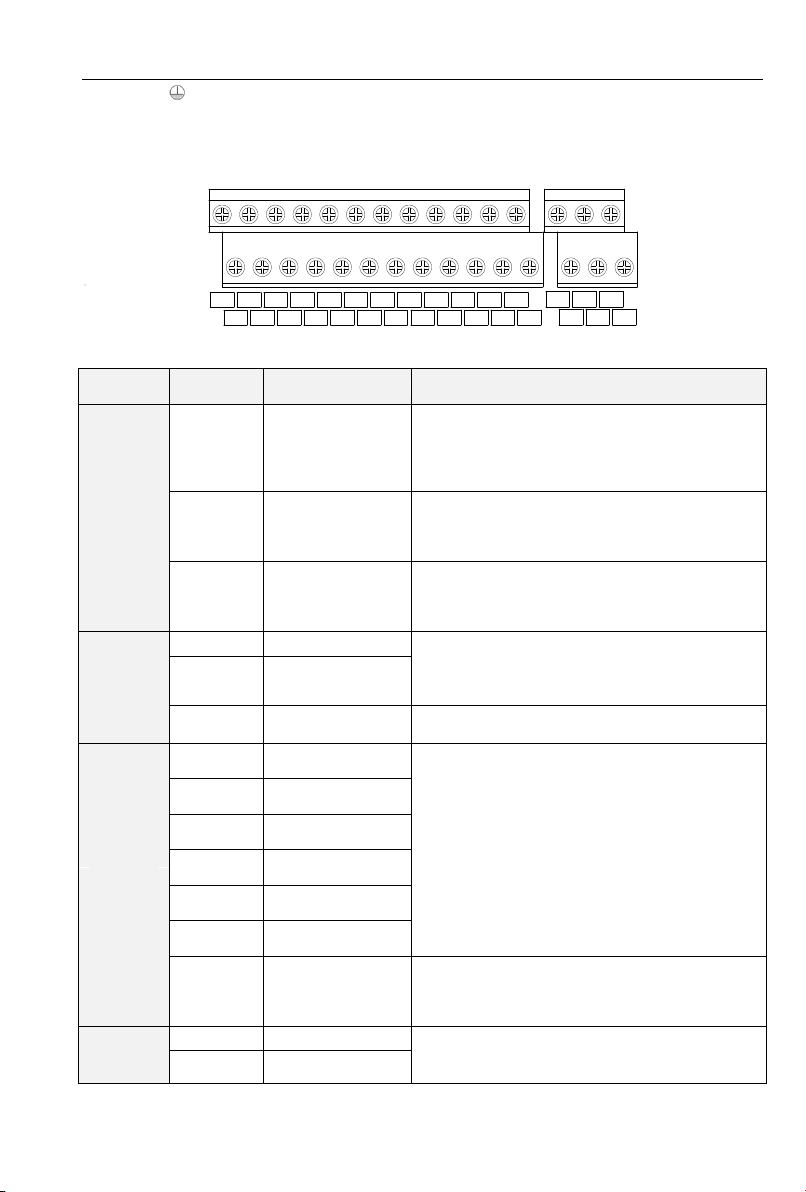

Figure 1-12 315~400kW main circuit terminals diagram

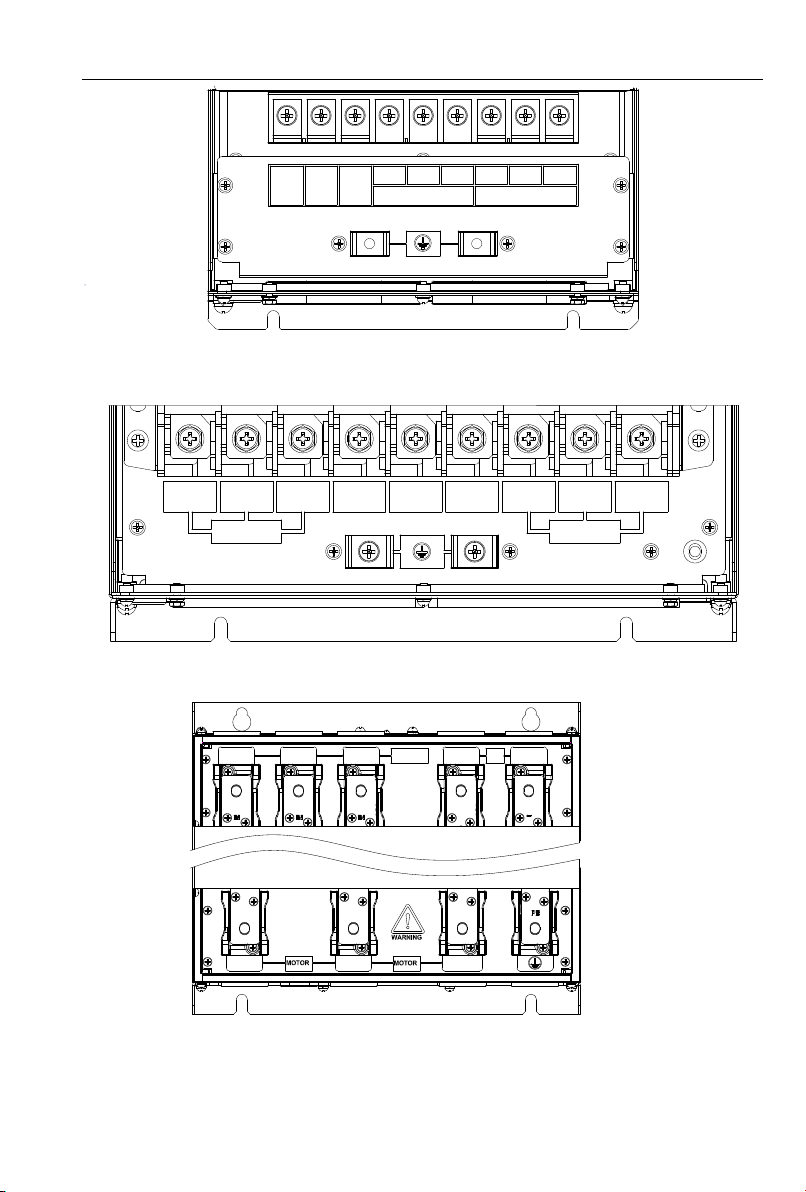

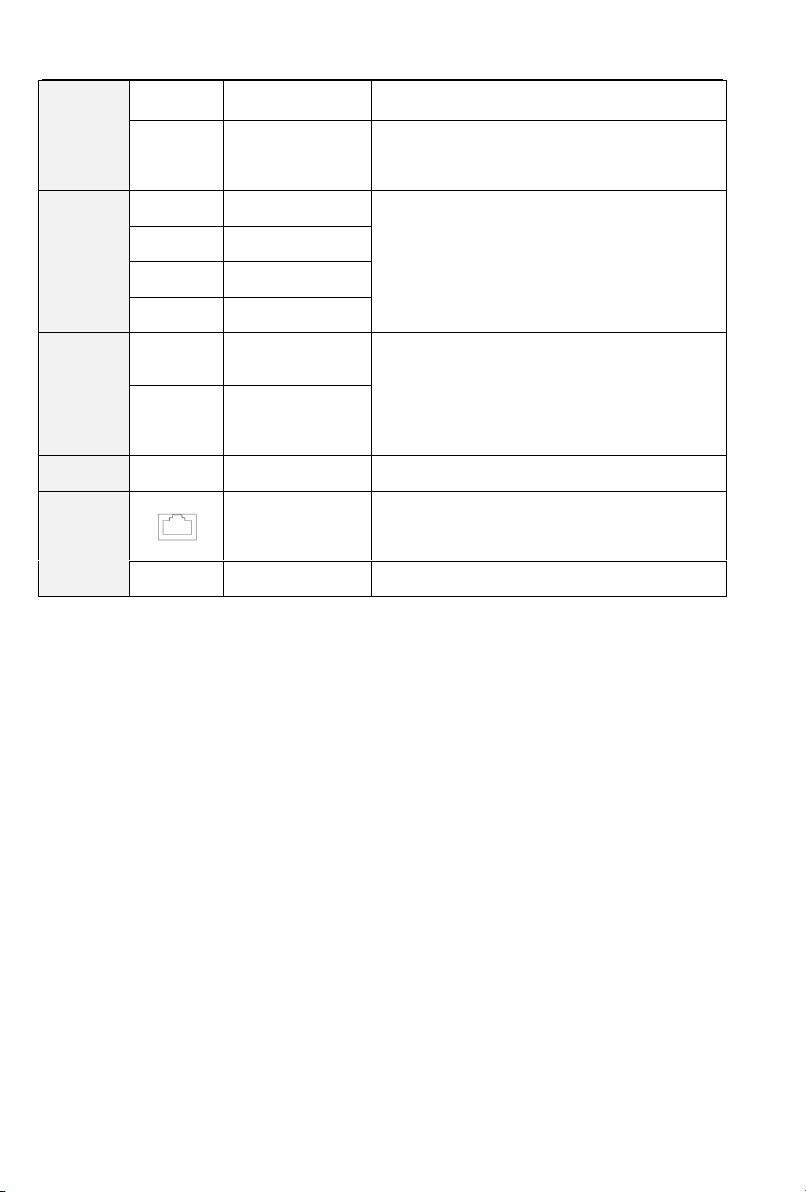

g:450-630kw main circuit terminals

RU/T1 V/T2 W/T3

(-)

POWER MOTOR

ST

DC+

DC

Figure 1-13 450~630kW main circuit terminals diagram

Table 1-3 circuit terminal functions

Designation and Function of Terminals

AC power input terminals for connecting to 3-phase

AC380V power supply.

AC output terminals of inverter for connecting to 3-phase AC

motor.

Positive and negative terminals of internal DC bus.

Connecting terminals of braking resistor. One end connected

to + and the other to PB.

Remarks: No phase sequence requirements on wiring of the input side of inverter. Wiring

Precautions:

1)Power input terminals R/L1、S/L2 、T/L3

◆The cable connection on the input side of the AC drive has no phase sequence requirement.

2)DC bus (+)、(-)

◆Terminals (+) and (-) of DC bus have residual voltage after the AC drive is switched off. After

indicator CHARGE goes off, wait at least 10 minutes before touching the equipment Otherwise, you

may get electric shock.

◆Do not connect the braking resistor directly to the DC bus. Otherwise, it may damage the AC drive

and even cause fire.

3)Braking resistor connection terminals (+)、PB

◆The cable length of the braking resistor shall be less than 5 m. Otherwise, it may damage the AC

drive.

4)AC drive output terminals U/T1、V/T2、W/T3

◆The capacitor or surge absorber cannot be connected to the output side of the AC drive. Otherwise,

it may cause frequent AC drive fault or even damage the AC drive.

If the motor cable is too long, electrical resonance will be generated due to the impact of distributed

capacitance. This will damage the motor insulation or generate higher leakage current, causing the AC

drive to trip in overcurrent protection. If the motor cable is greater than 100 m long, an AC output

reactor must be installed close to the AC drive.