PV series Solar Pumping Inverter

- 3 -

Contents

Preface..........................................................................................................................................................- 1 -

Contents .......................................................................................................................................................- 3 -

Chapter One Product Overview...............................................................................................................- 4 -

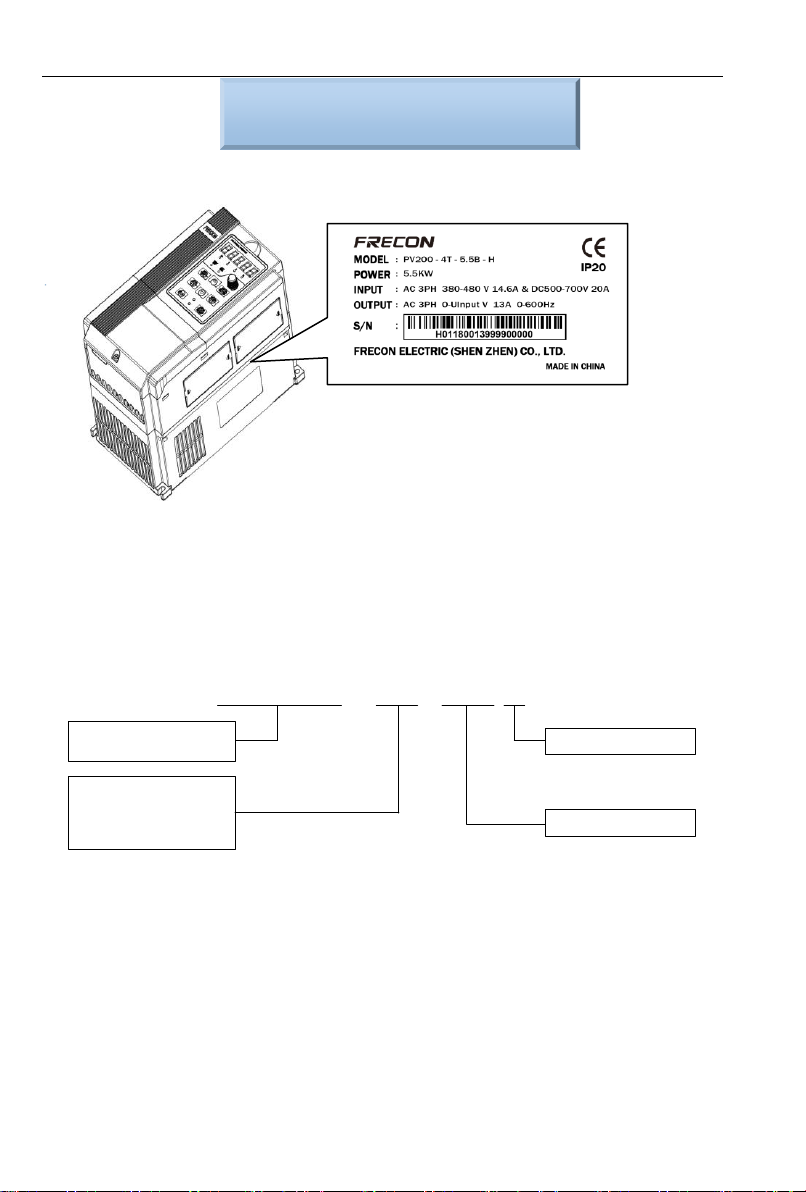

1.1 Name Plate........................................................................................................................................- 4 -

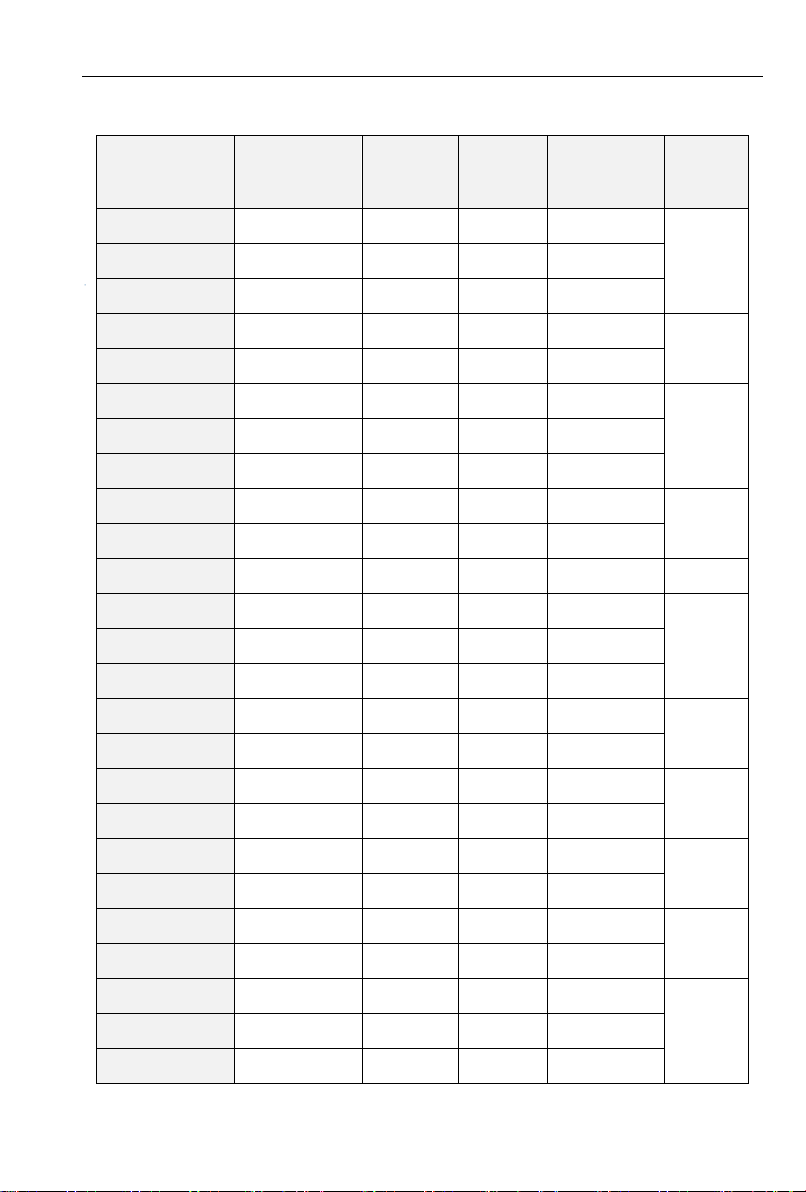

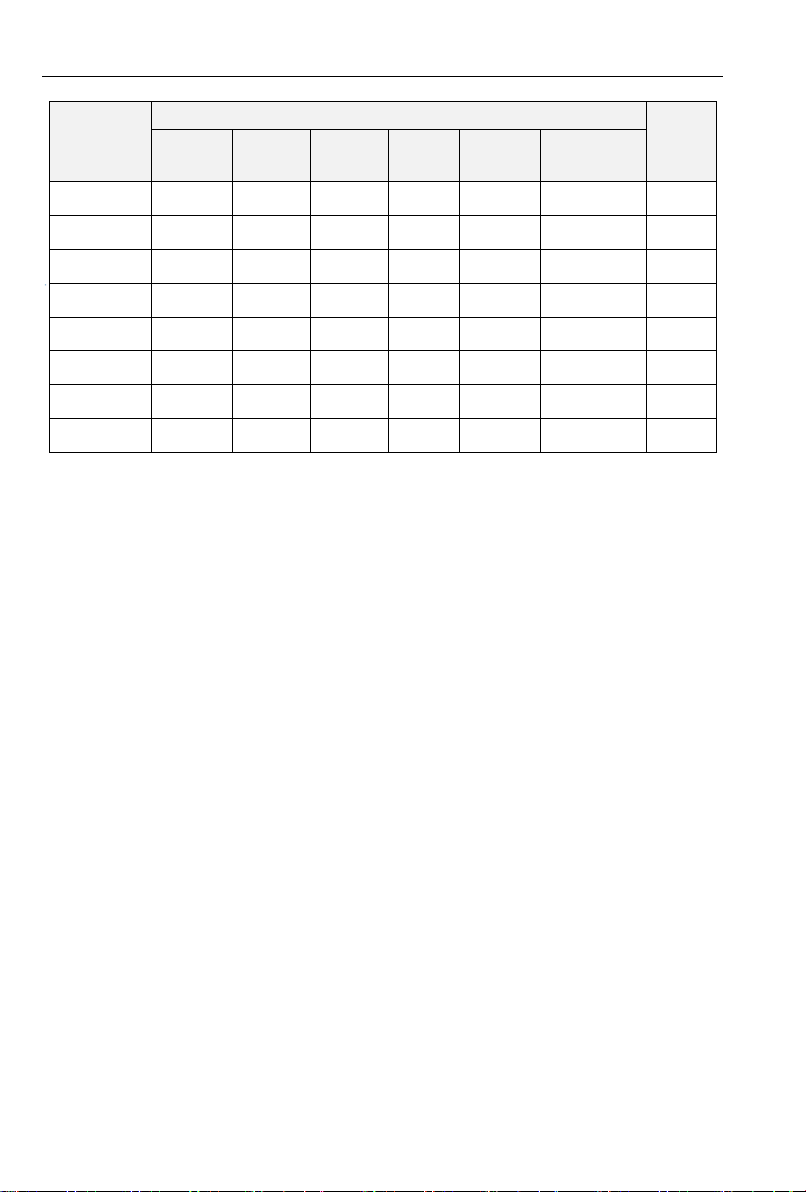

1.2 Product Specifications......................................................................................................................- 5 -

1.3 Dimension Drawing ..........................................................................................................................- 8 -

Chapter Two Commissioning Guide ....................................................................................................- 11 -

2.1 PV Panel Power Supply Commissioning.....................................................................................- 11 -

2.2 Grid or Generator power supply wirings......................................................................................- 13 -

2.3 Wiring diagram between VFD and single phase motor..............................................................- 15 -

2.4 Product Terminal Configuration....................................................................................................- 18 -

Chapter Three Function Parameters....................................................................................................- 22 -

3.1 The Basic Function Parameters....................................................................................................- 22 -

3.2 H00 Group: Detailed Explanation of Function Code ..................................................................- 39 -

Chapter Four Troubleshooting and Countermeasures....................................................................- 45 -