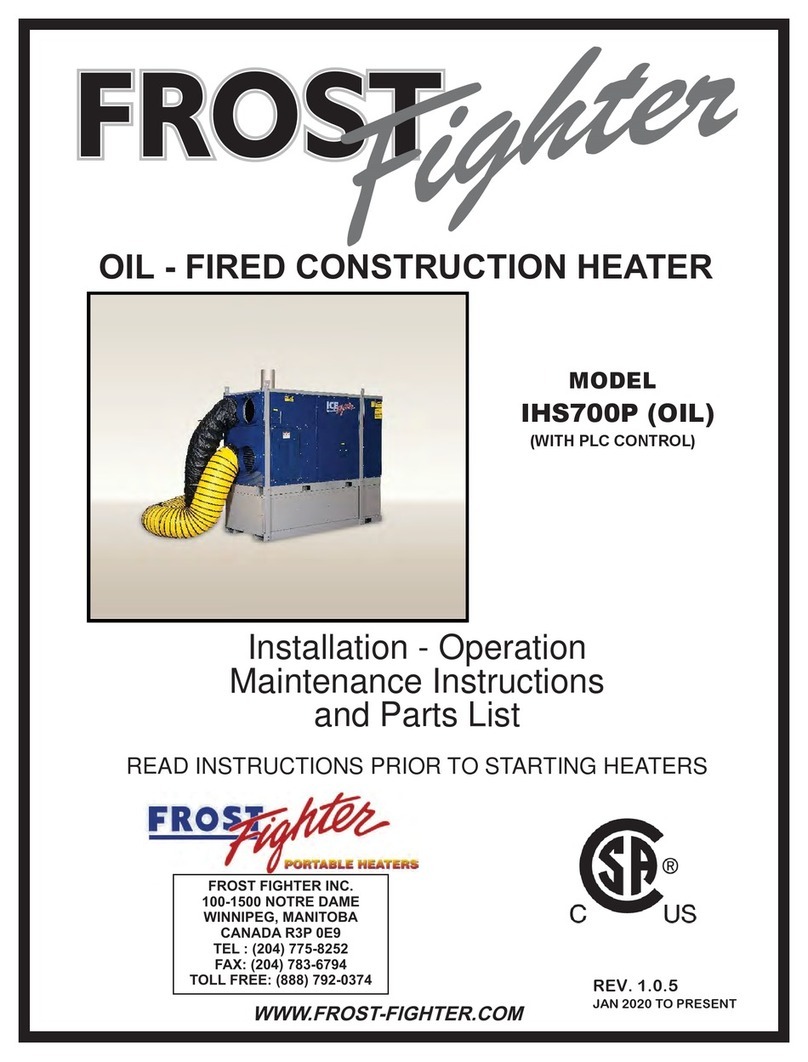

Frost Fighter IDH1000 User manual

Other Frost Fighter Heater manuals

Frost Fighter

Frost Fighter DF 400 User manual

Frost Fighter

Frost Fighter IDH1000 User manual

Frost Fighter

Frost Fighter IHS700P LP Datasheet

Frost Fighter

Frost Fighter IDH200QR OIL Guide

Frost Fighter

Frost Fighter IHS 1500 Manual

Frost Fighter

Frost Fighter IDF350-II General instructions

Frost Fighter

Frost Fighter IDHQR Series Datasheet

Frost Fighter

Frost Fighter IDF1000 User manual

Frost Fighter

Frost Fighter IDH400QR LP/NG Datasheet

Frost Fighter

Frost Fighter IDF500HS Datasheet

Popular Heater manuals by other brands

oventrop

oventrop Regucor Series quick start guide

Blaze King

Blaze King CLARITY CL2118.IPI.1 Operation & installation manual

ELMEKO

ELMEKO ML 150 Installation and operating manual

BN Thermic

BN Thermic 830T instructions

KING

KING K Series Installation, operation & maintenance instructions

Empire Comfort Systems

Empire Comfort Systems RH-50-5 Installation instructions and owner's manual

Well Straler

Well Straler RC-16B user guide

EUROM

EUROM 333299 instruction manual

Heylo

Heylo K 170 operating instructions

Eterna

Eterna TR70W installation instructions

Clarke

Clarke GRH15 Operation & maintenance instructions

Empire Heating Systems

Empire Heating Systems WCC65 Installation and owner's instructions