FUSION SPLICER 90S Rev5

2

Table of Contents

Safety Information............................................................................4

Bluetooth® Wireless Technology...............................................................7

General information .........................................................................8

Introduction.................................................................................................8

Wireless data communication ....................................................................9

Newly designed sheath clamp..................................................................11

Newly designed carrying case and work tray...........................................12

Other features ..........................................................................................14

Touchscreen Calibration ..........................................................................14

Description of product....................................................................16

Components of splicer..............................................................................16

Other necessary items for splicing operation...........................................17

Description of Splicer ...............................................................................18

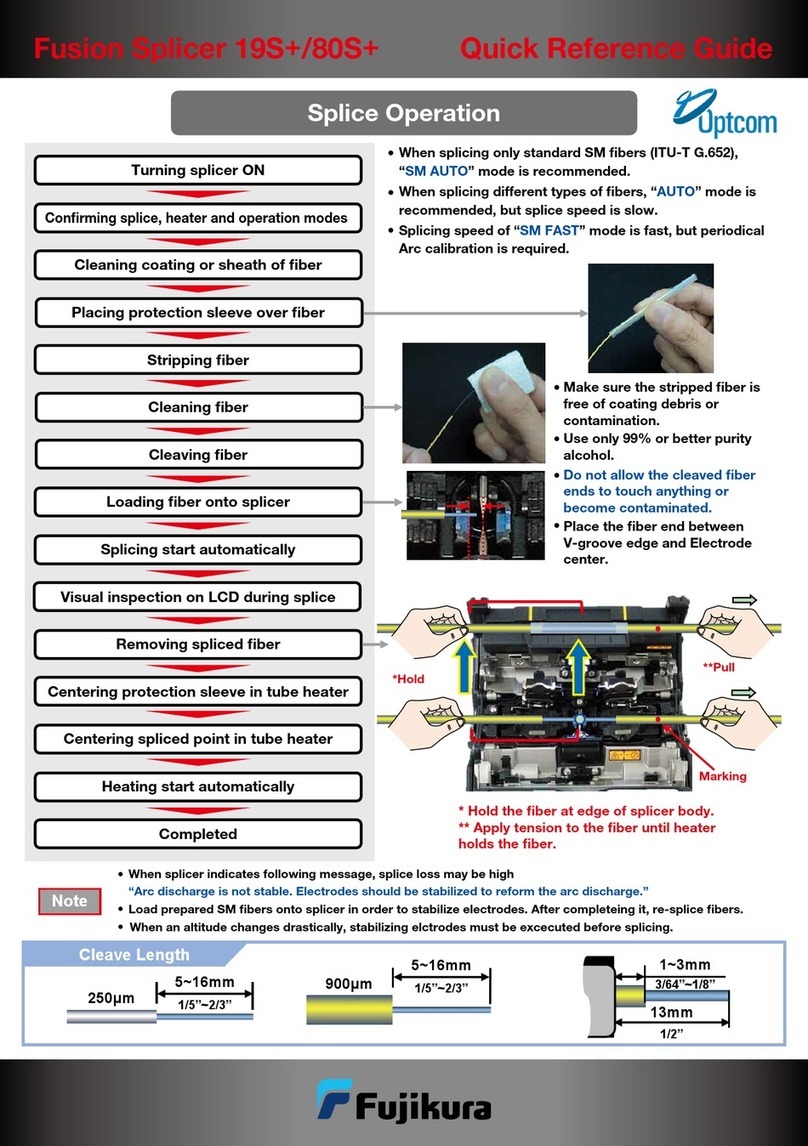

Basic Operation .............................................................................21

Splicing work preparation.........................................................................21

Power supply............................................................................................22

Battery Operation .....................................................................................23

Turning Splicer ON/OFF...........................................................................26

Splicer settings check / READY screen ...................................................27

LCD Brightness Adjustment.....................................................................28

Wireless communication with tools ..........................................................28

Wind-protector automatic opening-and-closing function..........................28

Operation mode........................................................................................29

Select of the Splice mode.........................................................................31

Select of the Heater mode........................................................................32

Preparation of fiber...................................................................................34

Fiber coating stripping and cleaning of bare fiber....................................34

Fiber Cleaving when using a sheath clamp .............................................34

Fiber Cleaving when using a Fiber Holder...............................................35

Loading fiber in splicer .............................................................................37

Wind-protector motion and sheath clamp motion.....................................38

Arc Calibration..........................................................................................38

Splicing procedure....................................................................................39

Storing splicing results .............................................................................42

How to input Mode Title/Comment/Password..........................................42

Fiber proof test .........................................................................................42

Heating protection sleeve.........................................................................43

Maintenance of Splicing Quality.....................................................45

Cleaning and Checking Before Splicing...................................................45

Periodical checking and cleaning.............................................................46

How to remove and install the Protrusion of the sheath clamp ...............48

Wireless data communication ........................................................50

Wireless data communication function of the splicer...............................50

How to establish wireless data communication .......................................51

How to turn off the wireless data communication ....................................52

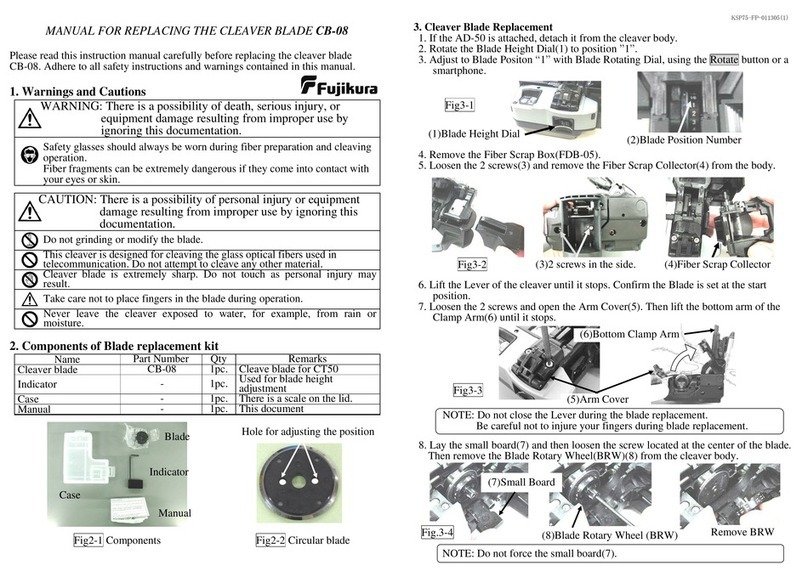

Blade Management Menu........................................................................54

Benefit of wireless data communication function.....................................54

Benefit of wireless security function “Smart Lock” ...................................56

Main Menu .....................................................................................58

Composition of Main Menu ......................................................................58

Splice mode menu..........................................................................59

Composition of Splice Menu ....................................................................59

Splice Mode .............................................................................................59

Heater Mode Menu.........................................................................70

Composition of the Heater Mode Menu...................................................70

Detail of the parameter in Heater Mode Menu.........................................73

Tube heating drop cable ..........................................................................74

Tube heating Splice-on-Connector ..........................................................74

Memory Menu ................................................................................75

Composition of the Memory Menu...........................................................75

Memory Menu Settings............................................................................75

Maintenance Menu.........................................................................77

Composition of the Maintenance Menu ...................................................77

Detail of the Maintenance Menu..............................................................77

Arc Calibration..........................................................................................77

Diagnostic Test ........................................................................................78

Dust Check...............................................................................................79

Motor Calibration......................................................................................79

Stabilize Electrodes..................................................................................79

Replace Electrodes..................................................................................80

Clear Arc Count........................................................................................80

Clear Cleaver Counter .............................................................................80

Battery Discharge.....................................................................................81

Motor Drive...............................................................................................81

Maintenance Info......................................................................................81

Splice Settings Menu......................................................................82

Composition of the Splice Settings Menu................................................82

How to change the settings......................................................................82

Other Settings Menu ......................................................................84

Composition of the Other Settings Menu.................................................84

Detail of the Other Settings Menu............................................................84

Machine Settings......................................................................................84

Supervisor Settings..................................................................................86