[MC850C Technical Data] (Specifications are subject to change without prior notice.)

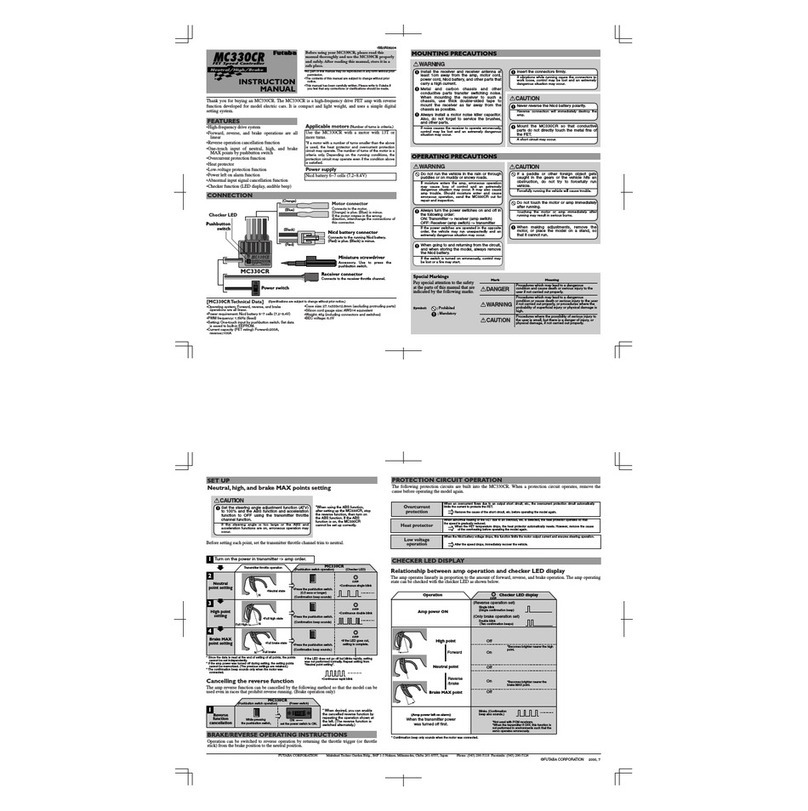

MOUNTING PRECAUTIONS

Accessories

• Schottky diode (for motor)

• Capacitors (for motor)

• Double sided tape

• Silicone flex wire (Red,Black,Blue)

• Heatshrink tube, red (x1), black (x1)

• Miniature screwdriver

(Use to press the pushbutton switch.)

Important:

Because the MC850C has pure race competition specifications, it is

designed so that it is difficult to operate the protection circuits. Use at an

overload may cause trouble. Incorrect power supply polarity or a power

supply or motor short circuit may cause the MC850C to burn out.

Install the receiver and receiver antenna away from the

amp, motor cord, power cord, Nicd battery, and other parts

that carry a high current.

Metal and carbon chassis and other conductive parts

transfer switching noise. When mounting the receiver to

such a chassis, use thick double-sided tape to mount the

receiver as far away from the chassis as possible.

Always install a motor noise suppresser capacitor. Also, do

not forget to service the brushes, and other parts.

If noise causes the receiver to operate erroneously, control may be lost

and an extremely dangerous situation may occur

Insert the connectors firmly.

If vibrations while running cause the connectors to work loose, control

may be lost and an extremely dangerous situation may occur.

Do not run the vehicle in the rain or through puddles or on muddy

or snowy roads.

If moisture enters the amp, erroneous operation may cause loss of

control and an extremely dangerous situation may occur. It may also

cause amp trouble. Should moisture enter and cause erroneous

operation, send the MC850C out for repair and inspection.

Always turn the power switches on and off in the following order:

ON: Transmitter -> receiver (amp switch)

OFF: Receiver (amp switch) -> transmitter

If the power switches are operated in the opposite order, the vehicle

may run unexpectedly and an extremely dangerous situation may

occur.

When going to and returning from the circuit, and when

storing the model, always remove the Nicd battery.

If the switch is turned on erroneously, control may be lost or a fire may

start.

Always perform a check of operation before running.

When making adjustments, remove the motor, or place the

vehicle on a stand, so that it cannot run.

When not set up correctly, the vehicle may run unexpectedly and an

extremely dangerous situation may occur.

MC8

1M23N17902

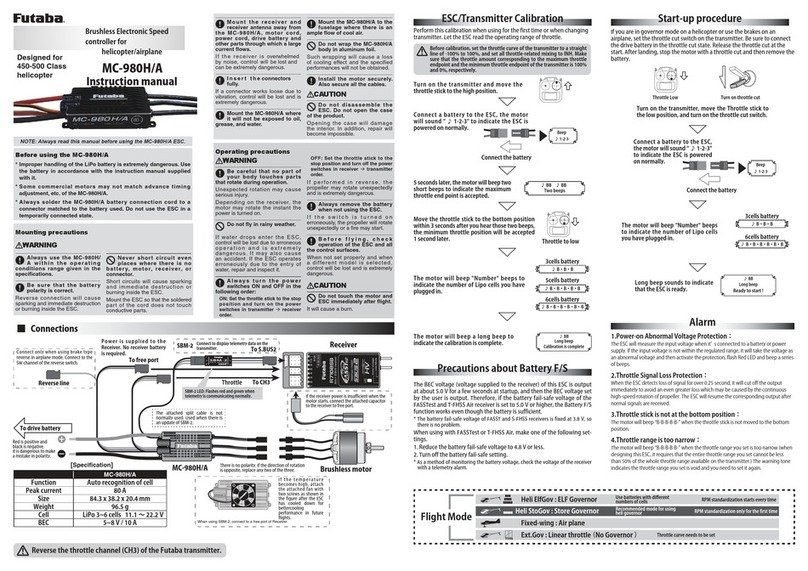

Serial communication function (Options)

The following settings and operations are possible with a Windows PC by using the optional interface unit (CIU-2).

*Windows is registered trademark of Microsoft Corporation.

Before using your MC850C, please read this manual thoroughly

and use the MC850C properly and safely. After reading this

manual, store it in a safe place.

• No part of this manual may be reproduced in any form

without prior permission.

• The contents of this manual are subject to change without

prior notice.

• This manual has been carefully written. Please write to

Futaba if you feel that any corrections or clarifications

should be made.

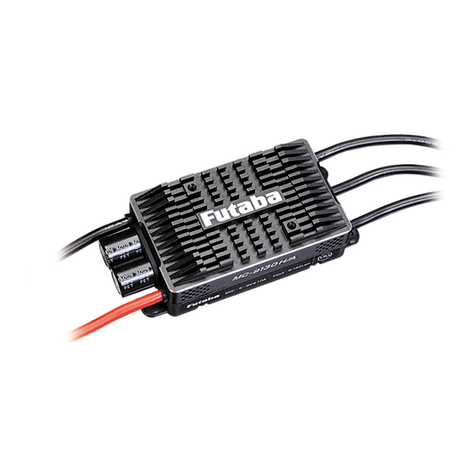

Thank you for purchasing an MC850C . The MC850C is a high-frequency drive FET speed control developed for model

electric cars. It is compact and light weight competition speed control, and uses a simple digital setting system.

Applicable motors (Number of turns is criteria.)

Use the MC850C with a motor with 5 turns or more.

*If a motor with a number of turns smaller than the above

is used, the heat protector and overcurrent protection

circuit may operate. The number of turns of the motor is

a criteria only. Depending on the running conditions, the

protection circuit may operate even if the condition

above is satisfied.

Power supply

Nicd, NiMH battery 4~7 cells

(4.8~8.4V)

FEATURES

• SMD MOSFETs with smallest internal resistance for

minimal losses and maximum power

• PWM frequency is Performed by load adaptive

•

The upper case made from aluminum

•Heat protector

•Low-voltage protection function

•Power left on alarm function

• External solder points with 12 AWG silicone flex wire

•

Terminal is Oxygen-Free-Copper

•

Serial communication function

INSTALLATION TIPS

• Mount the speed control in the model using the double-sided foam tape supplied.

• Provide plenty of cooling openings in the bodywork; this increases the performance and extends the life of all lectronic

components.

• Install the speed control in a location where it is protected from crash damage.

• The speed control should be installed in such a way that you have easy access to all connectors and the set-up button.

Important:

•Ensure that there is an adequate distance (approx. 3 cm) between the speed control and power cables and the receiver or receiver antenna. Avoid

direct contact between all power system components and the receiver or antenna, as this can cause interference. If you encounter interference

problems, re-position the components in the model.

•The antenna should be run vertically up and away from the receiver. Avoid contact with any parts made of carbon fibre or metal. See also the

instructions supplied with your radio control system.

• Operating system: Forward and brake (resolution:255)

• Power requirement: Nicd, NiMH battery 4~7 cells (4.8~8.4V)

• PWM frequency:

Forward:100Hz〜10kHz/Initial value:2.5kHz〜3.0kHz

Brake:2.0kHz

• BEC voltage: 6.0V (excluding at less than 6V)

• Setting: One-touch input by pushbutton switch.

• Current capacity (FET rating) :

Forward :840A (Momentary load: 3360A)

Brake :240A

• Case size: 28.7x26.2x14.5mm (excluding protruding parts)

• Silicon cord gauge size: AWG12 equivalent

• Weight: 17.5g (excluding connector, cords and switch)

Do not wrap your MC850C in foil.

It is important to provide a free flow of cooling air over it.

Do not remove the case of

MC850C

.

The MC850C may not be repairable.

Never reverse the battery polarity.

Reverse connection will immediately destroy the amp.

Mount the

MC850C

so that conductive parts do not directly touch

the solder parts of the input/output cord.

A short circuit may occur.

If a peddle or other foreign object gets caught in the gears

or the vehicle hits an obstruction, do not try to forcefully run

vehicle.

Forcefully running the vehicle will cause trouble.

Do not touch the motor or MC850C immediately after

running.

Touching the motor or amp immediately after running may result in

serious burns.

If the motor is connected to the speed control, you must not

run the motor by connecting a separate battery.

This will wreck the un

Turn the power switches on in the state where the vehicle is

floated.

When turnning on, depending on the receiver used, a motor may rotate

for a moment. Be careful not to injure a finger etc. by rotation of the

wheels.

MOUNTING PRECAUTIONS

Special Markings

Pay special attention to the

safety at the parts of this

manual that are indicated by

the following marks.

Mark Meaning

Procedures which may lead to a dangerous condition and cause death or serious injury to the user

if not carried out properly.

Procedures which may lead to a dangerous condition or cause death or serious injury to the user if

not carried out properly, or procedures where the probability of superficial injury or physical

damage is high.

Procedures where the possibility of serious injury to the user is small, but there is a danger of

injury, or physical damage, if not carried out properly.

Symbol: :Prohibited

:Mandatory

• Data logging function data read and erase (Data logging memorizes the running current and power supply voltage for

approximately 8 minutes at 1 second intervals.)

• Variable frequency range setting: 100Hz ~ 10kHz (Sets the load response system variable frequency range.) Dead

band: ±2µs ~ ±55µs (The neutral point range can be set.)

• Low battery protection voltage setting: 2.5V ~ 6.0V (Sets the voltage which cuts output to motor when the power

supply voltage is drops.)

• Current limiter: 50A ~ 300A, cancel (The current limit for suppressing wasted power can also be set and turned OFF.)

• Brake MAX duty: 0% ~ 100% (Sets the brake strength of the MAX brake point from neutral.)

• Neutral brake: 0% ~ 100% (Brake setting at the throttle neutral point)