6

-Clean the machine after every work and lubricate with oil to prevent corrosion.

-Use oil SAE-30 to lubricate the saw parts.

-Lubricate the vice parts occasionally.

-It is not necessary to lubricate drive wheels more frequently than annually except for cases of

overloading the saw.

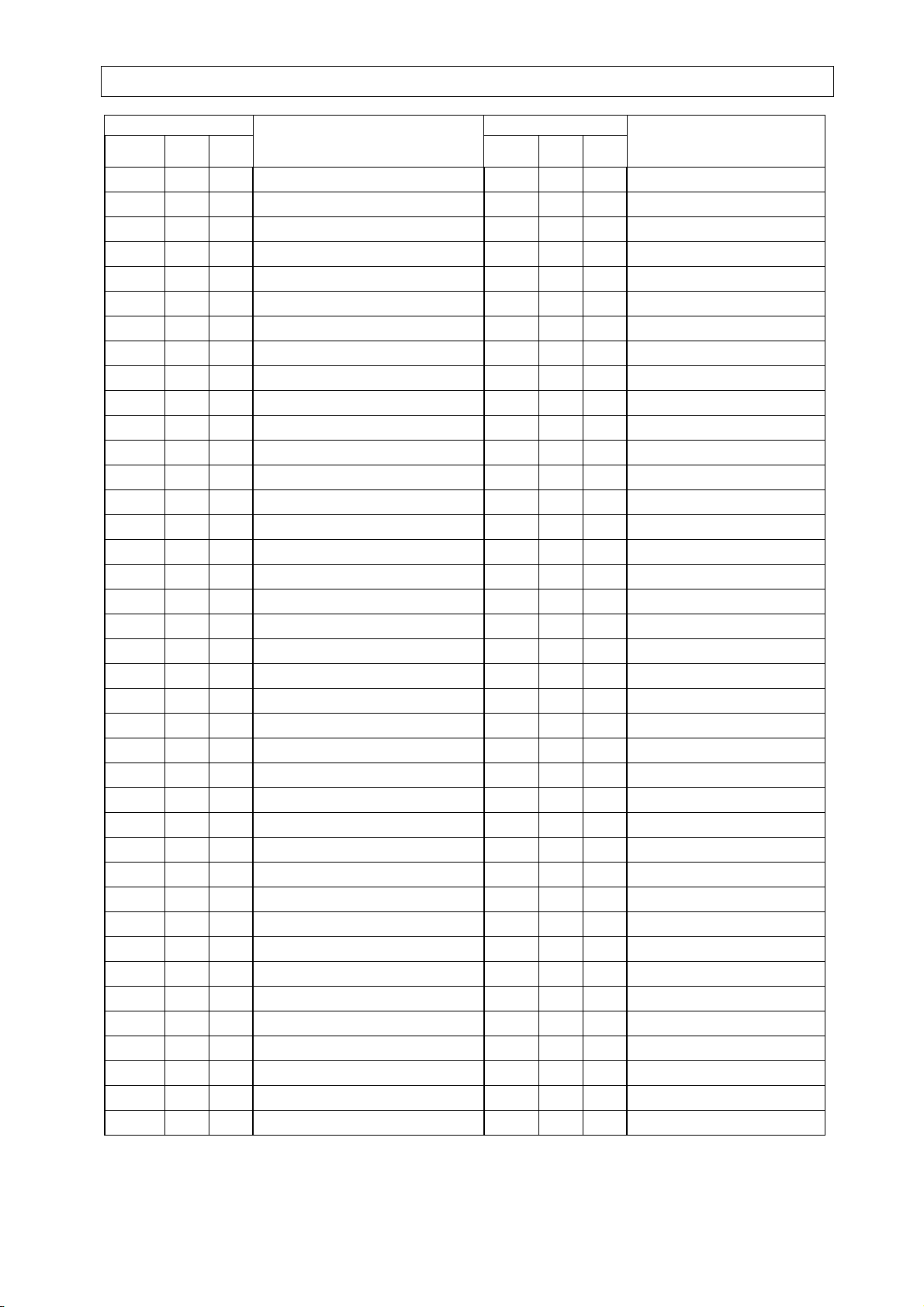

Troubles, Causes, Troubleshooting

Trouble Cause Troubleshooting

Saw band has broken

1. Material to be cut is loosen in

the vice

2. Wrong speed or wrong thrust

3. Too big gap between teeth

on the saw band

4. Work too coarse

5. Unfitting tension of the saw

band

6. The saw band bears on the

piece to be cut before the

motor is witched on

7. The band catches on the

drive or guide wheel rear

edge.

8. Poorly set up saw guide.

9. Too thick saw band

10. Weld crack

1. Tighten up the vice. h

2. Adjust the speed or thrust.

3. Replace the saw band with one

of smaller gap between the teeth

4. Set up the tension of the saw

band so that it will not slip on the

drive wheel when the motor is

switched on and runs at full

speed.

5. Set up the drive wheel so that it

is in parallel with drive wheel. h

6. Set up the saw guide.

7. Use a thinner saw band

8. Have it welded up at a specialist

The band gets blunt

quickly

1. Too coarse saw band

2. Too high speed

3. Inappropriate thrust

4. Hard elements in the material

5. Material too hard

6. The saw band scrolls up

7. Band tension insufficient

8. Band slipping

1. Use finer teething

2. decelerate

3. Reduce the tension of the spring

on the side of the tool. The thrust

will increase

4. Reduce the speed and increase

the thrust

5. Increase the thrust by decreasing

the spring tension

6. Replace the band with a new one

and set up the band tension

7. Increase the tension of the band

using the adjusting knob

8. Increase the tension of the band

using the adjusting knob

and slow down

Unusual wear on the saw

band rear side or from the

side

1. The saw band guide is not all

right any longer

2. The saw band guide bearing

is not set up correctly

3. Loose holding square or the

saw guide

1. Replace

2. Set up precisely m

3. Tighten up

Teeth of the saw band get

broken

1. Too coarse teething for the

given job

2. Too much thrust , too low

speed

3. The material to be cut is

vibrating

1. Use finer teething

2. Reduce thrust, accelerate

3. Tighten the material to be cut

4. Use coarser teething to remove

the sawdust with a brush