LIST OF FIGURES

Figure 1. Apollo 3000L Components .........................................................................................7

Figure 2. Underground Sump Enclosure Components...............................................................7

Figure 3. Apollo Underground Sump Front View........................................................................8

Figure 4. Main Product Feed Line Configuration .......................................................................9

Figure 5. Typical Feed Line Assembly.......................................................................................9

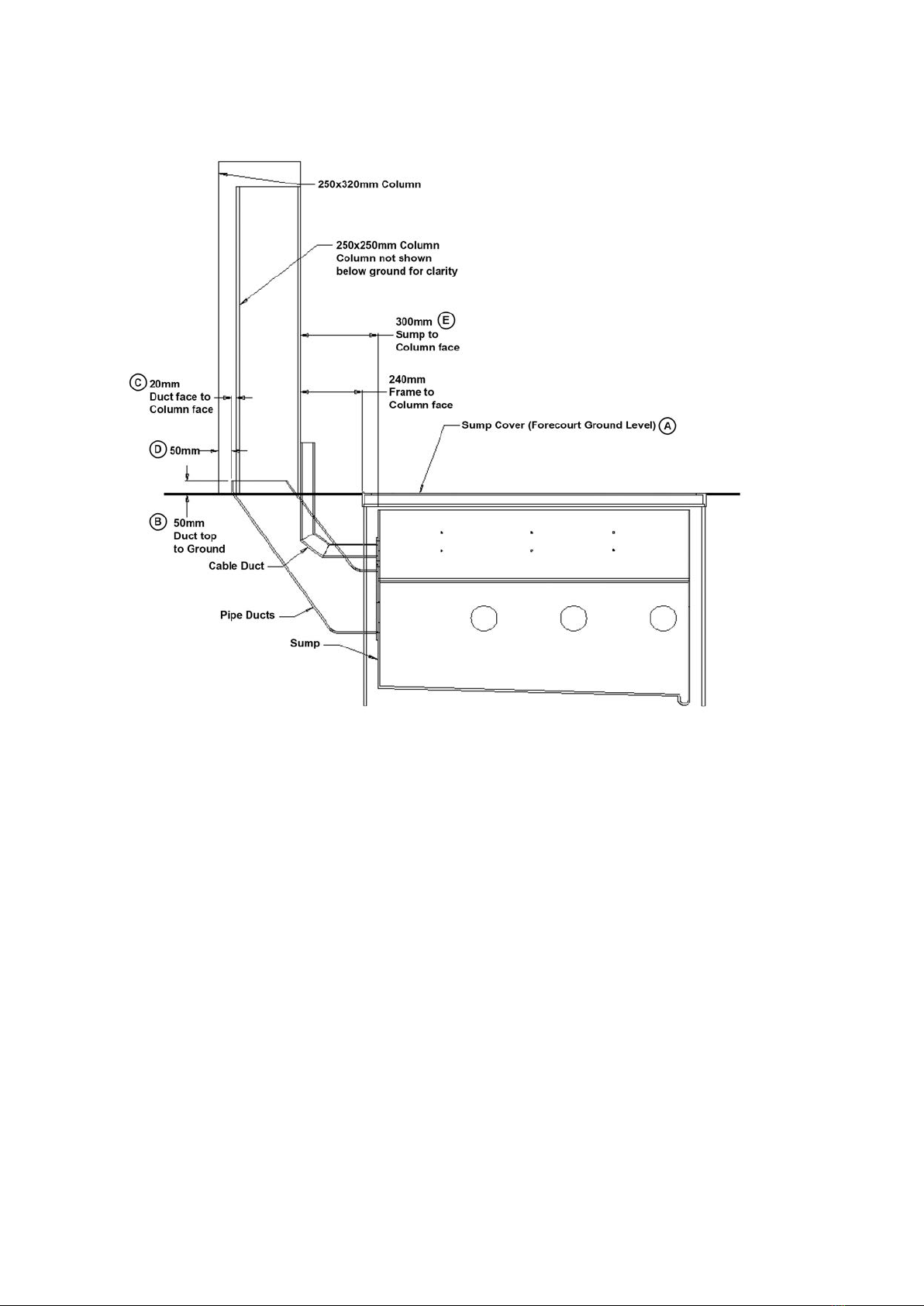

Figure 6. Apollo Sump/Column Position Top View...................................................................10

Figure 7. Vertical Delivery Pipes Assembly Components......................................................... 11

Figure 8. Vertical Delivery Pipes Assembly Mounting Positions...............................................12

Figure 9. Delivery Pipes Assembly Part Numbers....................................................................14

Figure 10. Head Cabinet Mounting Brackets.............................................................................15

Figure 11. Vent Box Position and Sealing Specifications...........................................................16

Figure 12. Safety Hose Position................................................................................................17

Figure 13. External Hose Positions...........................................................................................17

Figure 14. Apollo Sump and Modules Assembly........................................................................ 18

Figure 15. Product Delivery Hoses Connection.........................................................................19

Figure 16. Float Switch Assembly Installation............................................................................19

Figure 17. Solenoid Valves Cable Distribution...........................................................................20

Figure 18. Wiring Guide Decal..................................................................................................20

Figure 19. Apollo 3000L Electronic Set .....................................................................................21

Figure 20. Setting of Protocol Jumpers for PEC and Gilbarco Protocols....................................22

Figure 21. Comms Connections................................................................................................22

Figure 22. Motor Drive Module Connection Guide.....................................................................23

Figure 23. Solenoid Valves Connection Guide...........................................................................23

Figure 24. Multiplexer Module Connection Guide......................................................................24

Figure 25. Internal Comparison of Apollo 3000L Standard and VR2 ..........................................26

Figure 26. VR2 Nozzles............................................................................................................27

Figure 27. Coaxial Adaptor........................................................................................................27

Figure 28. Coaxial Adaptors and Splitter Bracket ...................................................................... 28

Figure 29. Fitting of Bracket and Backing Plate to Soffit Panel.................................................. 28

Figure 30. Soffit Panel, Splitter Bracket and Hoses in Place......................................................29

Figure 31. Splitter Bracket Cover in Place.................................................................................29

Figure 32. Complete Vapour Sensor Assembly..........................................................................33

Figure 33. Example Vapour Return Line Connection .................................................................34

Figure 34. VR Modules Connections......................................................................................... 35

Figure 35. Connections into the Bürkert Valve Controller........................................................... 35

Figure 36. Phoenix Connector for Vapour Sensor Cables..........................................................36

Figure 37. Phoenix Connectors on the Fafnir Unit.....................................................................36

Figure 38. Service Mode Function Screens............................................................................... 38

Figure 39. Adjustment Wheel....................................................................................................47

2A03229 APOLLO 3000L Installaon and Commissioning Manual Issue 1

4