GAT GM-820A-Dual User manual

GM-820A-Dual A/C SYSTEM MAINTENANCE CENTRE-DUAL

1

GM-820A-Dual

A/C System Maintenance Centre

R1234a & R1234yf

GM-820A-Dual A/C SYSTEM MAINTENANCE CENTRE-DUAL

2

NOTE:

1) Carefully read the user manual before using, and keep it well for future reference.

2) Carefully check the device parts list before using. For any doubt, contact GAT MACHINERY distributor

immediately.

3) Due to the product upgrade, tiny difference between the user manual and the device will not be further

noticed. Take the device as standard.

Copyright reserved! Without written agreement from GAT Machinery Co., Ltd (Hereinafter refer to

"GATMATIC "), any company or person is not allowed to copy and duplicate this user manual in any format

(electronic, mechanical, video, record or other formats).The user manual is designed only for GATMATIC

products.Any consequence caused by using the user manual to guide other device operation is not under

the responsibility of GATMATIC.

GATMATIC and its branches are not responsible for the fees and expense of the device damage and loss

due to private accident or from third party, misuse and abuse of the device, unauthorized change and repair,

or any operation and maintenance not following GATMATIC standard.

GATMATIC is not responsible for device damage or problem due to the usage of any optional parts or

consumables instead of GATMATIC original products or GATMATIC recognized products.

Declaration: Other product names mentioned in the user manual are aimed to describe the device usage.

The registered trademarks still belong to the original company.

The device is for professional technicians or maintenance and repair personnel.

Registered Trademark

GAT MACHINERY has registered its trademark in China and several other countries, logo is .

Other GATMATIC trademarks, service marks, dot names, Icons, company names mentioned in the user

manual all belong to GATMATIC and its subsidiaries. In those countries where GATMATIC trademark,

service mark, dot name, icon, company name not registered yet, GATMATIC declaim the right for its

unregistered trademark, service mark, dot name, icon, and company name. Trademarks of the other

products and company names mentioned in the user manual still belong to original registered company.

Without written agreement from the owner, no person is allowed to use the trademark, service mark, dot

name, icon and company name of GATMATIC or of other mentioned companies. You can visit

http://www.gattek.com to get contact with GATMATIC for the written agreement on the usage of the User

Manual.

GM-820A-Dual A/C SYSTEM MAINTENANCE CENTRE-DUAL

3

Safety

A. The machine is designed to be used and repaired by qualified personnel only.

B. The machine is designed to be used for R134a and R1234yf refrigerant. Other refrigerant types are not

applicable. Different types of refrigerants cannot be mixed, otherwise it is easy to cause equipment

failure or damage the air conditioning system.

C. Fill the A/C system with the quantity of refrigerant recommended by the manufacturer.

D. Keep away from moving parts and rotating elements such as cooling fans, alternators and heating

components, etc. to avoid harm.

E. Wear protective clothing gloves and goggles.

F. As automotive air conditioning pipe flushing, the operator must be fully familiar with automotive air

conditioning system and operation of the machine. Check whenever the engine is turned off that the

ignition key is turned to the full OFF position!

G. Do not expose the machine to direct sunlight or rain. Use only in well-ventilated work areas.

H. Never exceed 30 °tilt in transit process upside down is strictly prohibited.

I. Do not touch the machine high voltage power supply section, and do not maintain the machine as

power on.

J. Care of the manual.

K. We reserve the right to modify the contents of this document without prior notice to our customers.

GM-820A-Dual A/C SYSTEM MAINTENANCE CENTRE-DUAL

4

CONTENTS

1. Introduction...........................................................................................................................................5

1) Outline..................................................................................................................................................5

2) Features...............................................................................................................................................5

3) Specifications.......................................................................................................................................5

2. Functions..............................................................................................................................................6

1) Primary functions .................................................................................................................................6

2) Subsidiary functions.............................................................................................................................6

3. Operation..............................................................................................................................................7

1) Parts descriptions.................................................................................................................................7

2) First use................................................................................................................................................8

3) Preparations before Run Flushing function.........................................................................................9

4) Power On .............................................................................................................................................9

5) Flushing-Recovery............................................................................................................................. 11

6) Recovery/Recycling ...........................................................................................................................12

7) Vacuum ..............................................................................................................................................12

8) New oil adding....................................................................................................................................12

9) Recharging.........................................................................................................................................13

10) Auto. Mode.......................................................................................................................................14

11) Database..........................................................................................................................................14

12) Equipment Maintenance..................................................................................................................14

12-1) Exchange dry filter........................................................................................................................15

12-2) Clean pipe of the unit....................................................................................................................15

12-3) Calibration of load cell (operate by professionals).......................................................................15

12-4) Drain used oil................................................................................................................................15

12-5) Empty internal refrigerant .............................................................................................................15

12-6) Vacuum System Pipeline..............................................................................................................16

12-7) Change vacuum pump oil.............................................................................................................16

12-8) Discharge non-condensable gases..............................................................................................17

13) Supply tank.......................................................................................................................................17

14) System function................................................................................................................................18

14-1) Language......................................................................................................................................18

14-2) Units..............................................................................................................................................19

15) Equipment info.................................................................................................................................19

15-1) System inquiry ..............................................................................................................................19

15-2) Servicer info..................................................................................................................................19

15-3) Equipment info..............................................................................................................................19

16) Help..................................................................................................................................................20

GM-820A-Dual A/C SYSTEM MAINTENANCE CENTRE-DUAL

5

1. Introduction

1) Outline

GATMATIC GM seriesA/C system maintenance equipment is with the latest design technique which uses

the best control principle and the manufacturing process.

A/C System Maintenance Centre is intelligent equipment collecting of the A/C flushing, recovery, recycling,

recharging and other functions in one. It’s with the beautiful shape, humanized operation interface, and

advanced manufacturing processes to make the A/C maintenance professional and simple.

The machine is designed to be used for R134a and R1234yf refrigerant.

2) Features

A. For R134a and R1234yf refrigerant.

B. Fully automatic, easy to operate.

C. Internal pipeline of A/C system flushing, effectively cleared the internal greasy and fouling, to restore

the A/C system performance.

D. With forward flushing, reverse flushing, and pulse flushing functions, which greatly improve the

cleaning effect.

E. Using large-size glass tube with LED backlighting, can effectively observe the entire cleaning process.

F. Vertically installing the HP & LP gauges let the operator be able to observe the pressure parameters

timely even in the car.

G. Unique design of the pipeline to achieve the high recycling rate no matter with the gas or the liquid.

H. Easy to operate with the concise operating interface.

I. Designed with large size LCD.

J. Database.

K. Program and database can be updated.

L. With printer.

M. The self-cleaning function of the equipment can ensure that the refrigerant stored in the equipment

meets the reuse level.

3) Specifications

A. Working conditions:

Ambient temperature: 0~50°C

Relative humidity: <85%

B. Voltage input: □AC220V±10%~50/60Hz □AC110V±10%~60Hz (see as label)

C. Compressor:12.12cm3

D. Vacuum pump: 7.2m3/h,2Pa

E. Load cell for tank: 30kg/±10g, 2pcs

F. Load cell for oil bottle: 6kg/±5g

G. Tank: 12L, 2pcs

H. PAG oil bottle: 300ml

I. POE oil bottle: 300ml

J. Used oil bottle:500ml

K. LCD display: 240*128

GM-820A-Dual A/C SYSTEM MAINTENANCE CENTRE-DUAL

6

L. Working pressure: max. 20bar

M. HP gauge: -1bar~35bar

N. LP gauge: -1bar~20bar

O. Max. Work Pressure:20bar

P. Backlighting: LED

Q. Language: Chinese and English (can be customized)

2、Functions

1) Primary functions

A. Dual refrigerant system

B. Support dual refrigerant oil type

C. Automatic flushing

D. Automatic recovering/recycling

E. Automatic/manual used oil drain

F. Vacuum timing.

G. Automatic/manual new oil injection

H. Quantitative recharging

I. Each function can operate independently

J. Auto mode

K. Database

L. Print

2) Subsidiary functions

A. Parameter setting

B. Refrigerant supplement

C. Pipeline self-cleaning

D. Equipment emptying

E. Equipment vacuum

F. Electronic scale calibration (professional)

G. Machine maintenance (Dry-filter exchanger, vacuum pump oil exchanger)

H. Printer test

I. Equipment status query

J. Equipment info inquiry

K. Help

GM-820A-Dual A/C SYSTEM MAINTENANCE CENTRE-DUAL

7

3. Operation

1) Parts descriptions

HP gauge

Alarm

LCD display

Keys

R134a

HP port

R1234yf

HP port

LP gauge

Printer

R134a

LP port

R1234yf

LP port

Window

Power switch

Power socket

R134ATank

R1234YF Tank

Used oil bottle

New oil bottle

POE bottle

Vacuum pump oil

observe window

GM-820A-Dual A/C SYSTEM MAINTENANCE CENTRE-DUAL

8

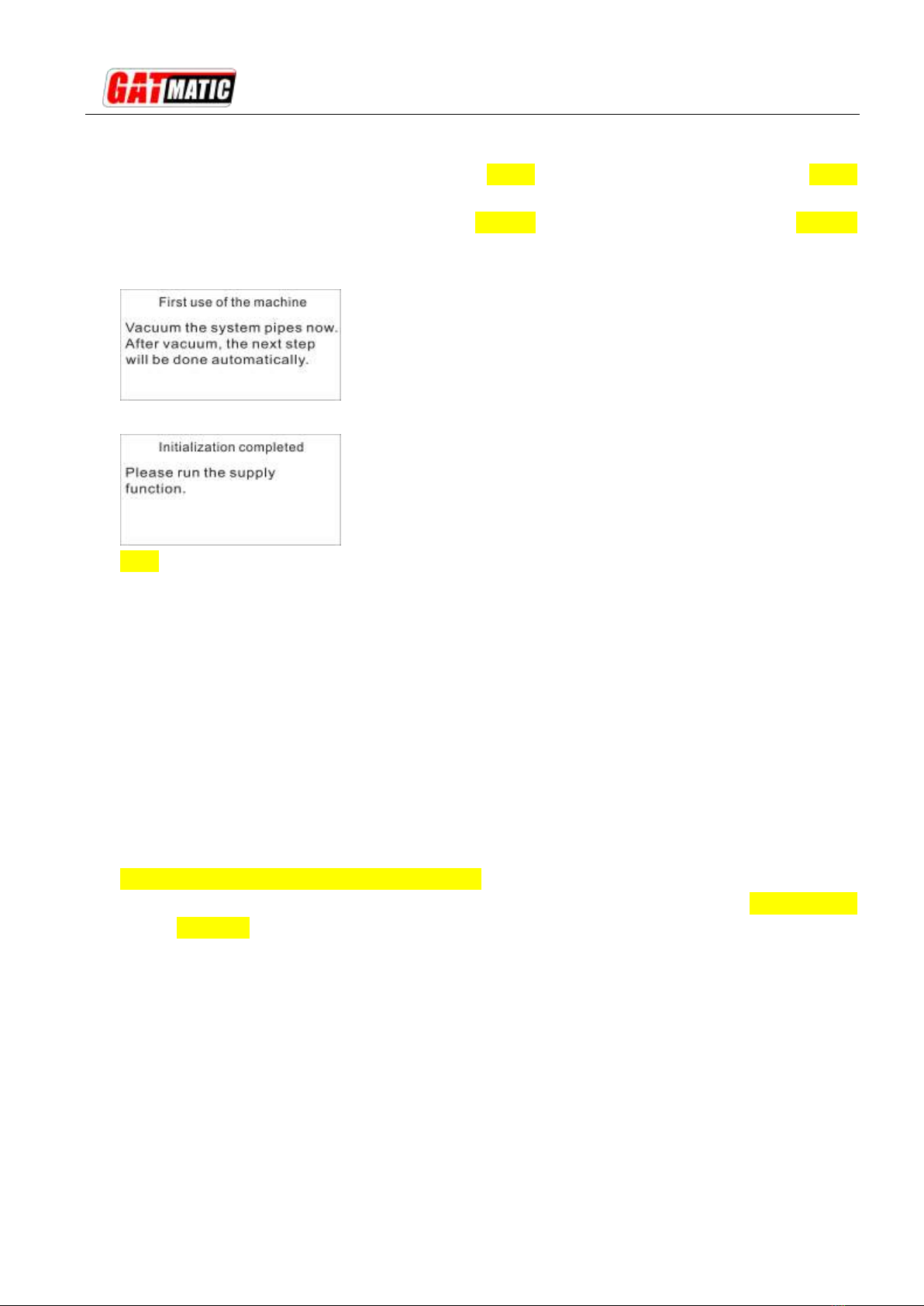

2) First use

A. In order to avoid damage to the electronic scale during transportation, the electronic scale is protected

when shipped. Open the back door, take out all the fillers on both sides of the tank and under the scale

pan, and loosen the supporting screw under the scale plate to make the scale handle the suspended

state.As shown in the figure below:

B. Connect the power supply and power on. Please operation as following.

C. Set the language: select one and press ENTER.

C、Set the units: select one and press ENTER

D. Install the R1234yf storage tank back of the machine.

a) Place the storage tank on the rear scale and fix it.

b) Connect the red and blue pipes to the red and blue valve interfaces of the tank, tighten them (it is

recommended to apply a small amount of stop glue), and open the two valves.

E. Connect the hoses and couplers

Loosen

GM-820A-Dual A/C SYSTEM MAINTENANCE CENTRE-DUAL

9

a) Connect the two RED hoses to the HP ports.

b) Connect the two blue hoses to the LP ports.

c) Connect the RED and BLUE couplers of R134a to the RED and BLUE pipes of R134a

respectively.

d) Connect the RED and BLUE couplers of R1234yf to the RED and BLUE pipes of R1234yf

respectively.

F. Initialization

G. Supply refrigerant to the new equipment (please refer to the SUPPLY FUNCTION section)

Note:

As the new equipment is empty, the Flushing and Recharging functions will not be performed.

In order to ensure all functions normal, about 4kg R134a and 4kg R1234yf refrigerant need to be

filled to the tanks. If it is not necessary to use the Flushing function, replenish at least 2kg.

H. Please read this user manual carefully before operating.

3) Preparations before Run Flushing function

A. Check the refrigerant type of the automobile air conditioning, and connect the right couplers to the A/C

service ports, and open the couplers on.

B. Start the car, and run theA/C for about 5 minutes.

C. Check whether the high and low pressure of A/C is normal. Check whether there is abnormal noise

when the compressor works. If there is any abnormality, it must be repaired first.

D. Turn off the air conditioner and turn off the engine.

E. Empty the used oil bottle. Add an appropriate amount of new oil into the new oil bottles (Note: PAG and

Poe types).

F. Turn on and prepare for work.

Warning: When the machine is running, never to run the A/C system!

4) Power On

A. If the equipment detects abnormal information, it will give a prompt, which should be handled in time. If

there is no prompt message, it will go to the next interface directly.

GM-820A-Dual A/C SYSTEM MAINTENANCE CENTRE-DUAL

10

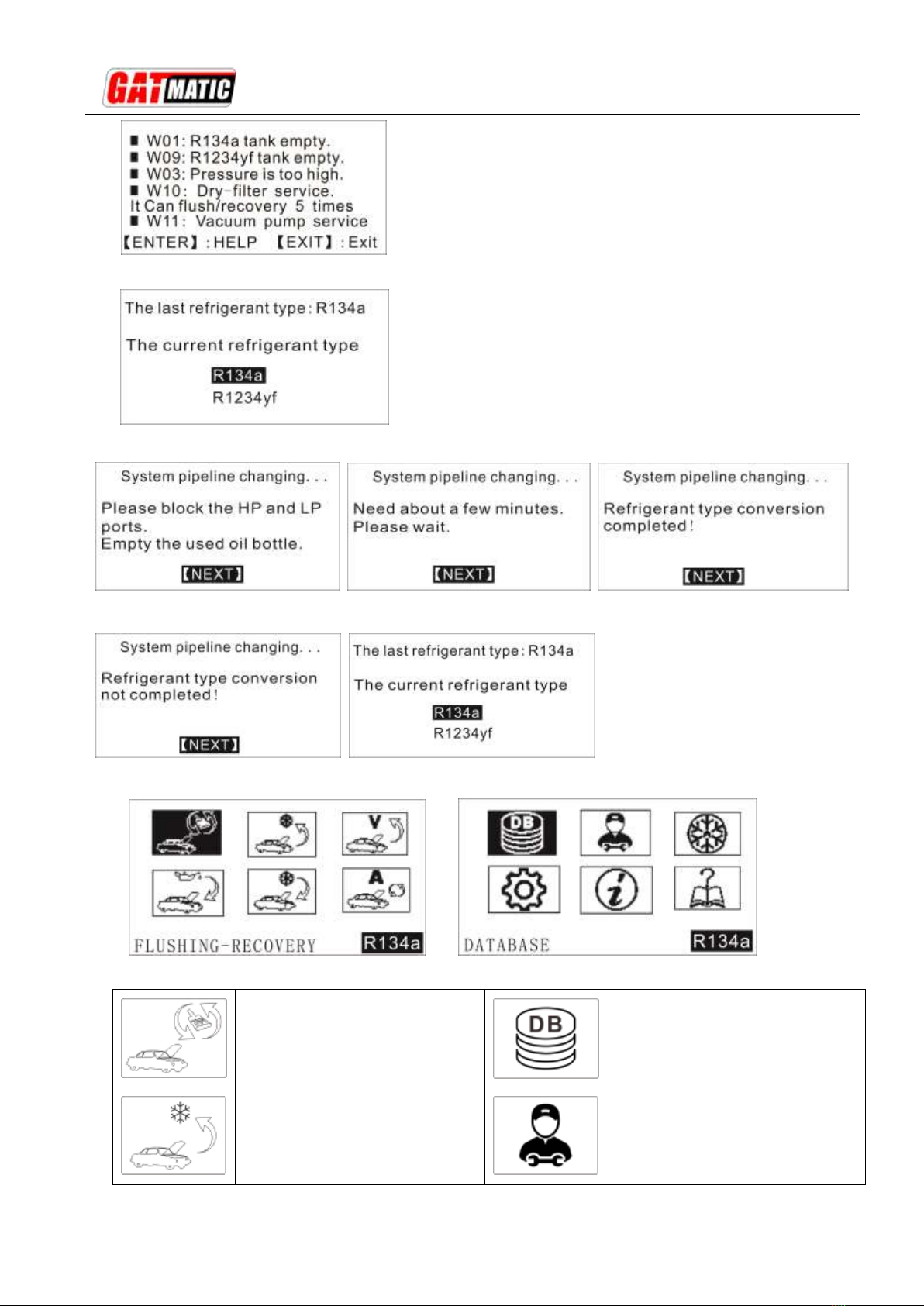

B. Select the refrigerant type: R134a or R1234yf. The default is the last operation type.

C. If the refrigerant type is different from last time, please operate according to the prompts.

If the process is terminated artificially, it will can’t be into the main function and back to the last Interface.

D. After completion, enter the function interface.

Description:

Flushing- Recovery

This function include flushing

and recovery process.

Database

Check the amount of Refrigerant

& oil

Recovery

Recovery the refrigerant of A/C

system.

Equipment Maintanance

Exchange dry-filter, Pipe-line

cleanning, Calibration load cell.

GM-820A-Dual A/C SYSTEM MAINTENANCE CENTRE-DUAL

11

Vacuum

Timing vacuum.

Supply Refrigerant

Transfer the refrigerant into the

equipment tank.

New oil adding

Fill the new oil into A/C system.

System function

Supply,Parameter

setting,Exchange filling

tank,Change refrigerant type

Recharging

Recharge quantitative.

Equipment info

System info,Servicer info,

Equipment info.

Auto. Mode

Automatically all the process.

Help

Descriptions of the alarming

code.

5) Flushing-Recovery

A. By this function, it will be able to clean out the refrigerant oil and oil sludge to exchange the refrigerant

entirely to improve the performance of compressor. And also it will recover the refrigerant remained in

the A/C system.

B. Before flushing the pipeline of automotive A/C system, please turn on A/C system and run it for 5 to 10

minutes.And set it as the lowest temperature and medium wind.

C. Turn off the automotive air conditioning.

Warning: do not start the air conditioning during the flushing process! Otherwise, it easily

causes damages to the air-conditioning and risk of accident!

D. In order to achieve good flushing performance, the flushing time should be more than 20 minutes.

General: the cleaning time for single-evaporator is 20 minutes, and that for double-evaporator is about

30 minutes. The longer the cleaning time, the better the cleaning effect.

Note: The flushing time does not include the time of recovery process. Once the flushing is

finished, the machine will run the recovery function automatically.

E. Operations:

E-1: Select the Flushing Function and press the ENTER key.

E-2: Set the flushing time.

E-3: Press the ENTER key to start.

F. During the working, it can automatically carry out forward, reverse and pulse cleaning, and

automatically discharge the used oil separated from the cleaning into the old oil bottle.

G. After the cleaning process, it will automatically recover the refrigerant. According to the ambient

temperature and the structure of the A/C system, the recovery process will last for 10-30 minutes.

Please do not manually terminate the work.

H. When finished, it’ll stop automatically. And it will discharge the separated used oil again, and then shut

down automatically and give a prompt.

GM-820A-Dual A/C SYSTEM MAINTENANCE CENTRE-DUAL

12

Notice: it’s normal for that there have action sound of the solenoid valve during the working

process. Please do not stop it. The used oil can be drained out automatically.

Warning: In case of sudden power failure or accidental termination during the Flushing-Recovery

process, please re select the Flushing-Recovery function. The cleaning time can be set shorter and

then run again. It is important not to operate other functions.

6) Recovery/Recycling

A. By this function, it will recover the refrigerant remained in the A/C system.

B. Operations:

B-1: Select the Recovery Function and press the ENTER key.

B-2: Press the ENTER key to start.

B-3:After recovery over, it’ll drain the used oil automatically.

C. When finished, it will discharge the separated used oil, and then stop automatically.

7) Vacuum

A. By this function, it will clean the water vapor out from the A/C system.

B. It should be more than 15 minutes. Generally, it needs 15 minutes at least for the air conditioning only

with front wind and 20 minutes for with the front and rear wind.

C. Operations:

C-1: Select the Vacuum Function and press the ENTER key.

C-2: Set the vacuum time.

C-3: Press the ENTER key to start.

D. When finished, it’ll stop automatically.

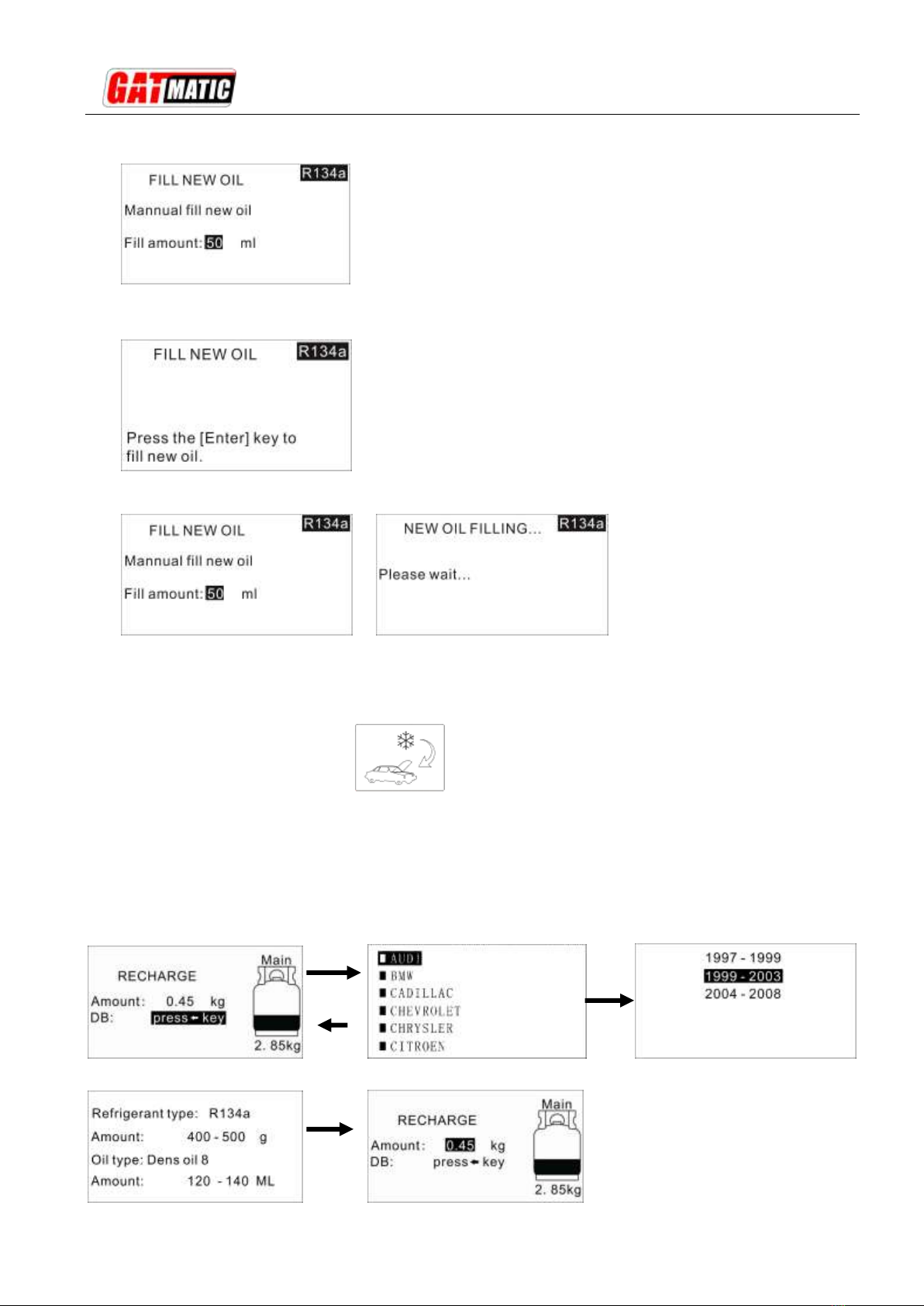

8) New oil adding

A. It must be able to do after vacuum process.

B. Pour new oil into the new oil bottle.

Note:

1) Add new oil more 20ml than the used oil drained out to avoid the air into the air

conditioning system.

2) Pour the new oil into the corresponding oil bottle. PAG oil into the PAG bottle and POE oil into the

POE bottle. The two types of oil cannot be mixed, otherwise it will cause damage to the air

conditioning system. Please check the vehicle technical manual or label, do not add the wrong

type!

3) If a non-vacuum state is detected, the function cannot be run.

C. Operations:

C-1: Select the New oi adding Function and press the ENTER key.

GM-820A-Dual A/C SYSTEM MAINTENANCE CENTRE-DUAL

13

C-2: Set the oil type. Must be correct!

C-3: Select method: you can choose manual control, or set the filling amount.

C-3.1 If you select Manual control, press and hold ENTER key for injection, and release the key to

stop.

C-3.2 If set the filling amount, press ENTER key after set, and it will stop automatically.

9) Recharging

A. Select the Recharging Function and press the ENTER key.

B. Set the recharge amount.

C. Press the ENTER key to start.

D. When finished, it’ll stop automatically.

Note: The recharging amount setting as following.

Method 1: Set the amount directly.

Method 2: Set the amount by the database. Steps as following:

Press

key

ENTER

GM-820A-Dual A/C SYSTEM MAINTENANCE CENTRE-DUAL

14

Note: In the recharging process, if shows the menu, it

means that you need to turn on the car air-conditioning to

complete the recharging process. Later, you should

supply new refrigerant into the tank.

10) Auto. Mode

A. Under this mode, all of the functions can be run full automatically after setting the parameters.

B. Before running, must drain out the used oil entirely and fill enough new oil into the new bottle. Pay

attention to the oil type.

C. Operations:

C-1: Select theAuto. Mode Function and press the ENTER key.

C-2: Set the all parameters.

or

C-2: Press the ENTER key to start.

D. When finished, it’ll stop automatically.

11) Database

Here you can read the refrigerant type and filling amount and the refrigerant oil type and

filling amount of the automotive.

12) Equipment Maintenance

GM-820A-Dual A/C SYSTEM MAINTENANCE CENTRE-DUAL

15

12-1) Exchange dry filter

A. The dry filter must be exchange when it reaches the life time. There will give a message.

B. If not exchange the dry-filter timely, it will not be able to run the recovery, flushing and supplying

functions.

C. Operations:

C-1: Please check the ID of the dry-filter at the label. Which is the SN.

C-2: Select Exchange dry-filter Function and press ENTER key.

C-3: Input the ID.

C-4: And then do step by step as the information.

Note: Please attention the mounting direction of the dry-filter.

12-2) Clean pipe of the unit

A. Through this function, it can effectively remove the oil mist and trace moisture in the internal pipeline of

the equipment, and ensure that the system is clean and pollution-free.

B. After a period of use, such as 3months, it should be run this function.

C. Operations:

C-1: Power on, select refrigerant type, then select Equipment Maintenance.

C-2: Select Clean Pipe of The Unit function and press ENTER key.

C-3: Connect the hoses and couplers well to the coupling side of the equipment, and open the

couplers.

C-4: And then press ENTER key to run.

Warning: this function is performed according to the type of refrigerant.

12-3) Calibration of load cell (operate by professionals)

A. When the load cell is not precise, it needs to be calibrated.

B. You need input the password 1510 before use this function.

C. If do the calibration of main tank load cell, please prepare a 10~20kg weight.

If do the calibration of oil bottle load cell, please prepare a 1-3kg weight.

D. Follow the prompts step by step.

Note: if here have some programs, please check according to the messages.

12-4) Drain used oil

A. It can control the used oil drained manually.

B. Select Drain Used Oil function and press ENTER key.

C. Press and hold ENTER key to drain, and release the key to stop.

12-5) Empty internal refrigerant

A. Through this function, the refrigerant in the equipment can be emptied.

B. It is necessary to use another refrigerant recovery equipment (say as MM).

C. Operations:

GM-820A-Dual A/C SYSTEM MAINTENANCE CENTRE-DUAL

16

C-1: Connect the HP & LP ports of the equipment with the HP & LP ports of the MM. Pay attention to

the type of refrigerant.

C-2: Select Empty Internal Refrigerant function and press ENTER key.

C-3: Confirm the pipes connected well, and press ENTER key.

C-4: Run Recovery function of MM.

C-5: After recovery end, stop and power off the MM. And then press ENTER key to the next step.

C-6: Wait for a moment. When it shows END, the pipes connected with two equipment can be

disconnected.

C-6: Run the Vacuum System Pipeline function.

Warning: this function is performed according to the type of refrigerant.

12-6) Vacuum System Pipeline

Through this function, the internal pipeline of the equipment can be completely vacuumed to the factory

state.

Before run this function, it must do the Empty Internal Refrigerant function.

Operations:

C-1: Power on, select refrigerant type, then select Equipment Maintenance.

C-2: Select Vacuum System Pipeline function and press ENTER key.

C-3: Connect the hoses and couplers well to the coupling side of the equipment, and open the

couplers.

C-4: And then press ENTER key to run.

Warning: this function is performed according to the type of refrigerant.

12-7) Change vacuum pump oil

A. When the pump oil became cream or machine display maintenance message, the vacuum pump oil

must be changed.

B. If not change the pump oil in time, the vacuum pump will be easily damaged.

C. Operations:

C-1: Open the back-down cover.

C-2: Unscrew the block of the drain port to drain the old oil out entirely. Then re-back the block to the

drain port.

Note: the oil drain hole is on the same side of the window or at the bottom. There are some differences

in specifications.

C-3: Unscrew the cap of the fill port and then fill the new oil slowly into the vacuum pump until the oil

level reach at the center site. Then re-back the cap to the fill port.

Window

Drain port

Fill port

GM-820A-Dual A/C SYSTEM MAINTENANCE CENTRE-DUAL

17

Note: the new vacuum pump oil cannot be filled too much into the vacuum pump otherwise it will spray

out when working.

C-4: Re-back the cover.

12-8) Discharge non-condensable gases

A. Due to some uncontrollable reasons, after a period of time, some incompressible gas will be

accumulated in the tanks. If the gas is too much, it will cause abnormal operation of the equipment.

B. It is necessary to discharge non-condensable gases regularly, and it is recommended to do it once a

month (if the use frequency is low, the exhaust cycle can be extended). Or, when the machine appear

the High-pressureAlarm, it need do it immediately.

C. Operations:

C-1: Remove the rear refrigerant tank and place it aside. Note: do not remove any pipes!

C-2: Open the back door, and there are two exhaust valves in the left middle of the machine. Open the

valve slowly to discharge non-condensable gases.

Attention: slowly rotate the valve handle, stop the rotation when you hear the exhaust sound, and let

the exhaust stand still.

Left valve -R1234yf tank exhaust Right valve - R134a tank exhaust

C-2: The exhaust time is about 20 seconds.

Warning: when exhausting, it is necessary to cut off the power supply and carry out it in a ventilated

environment, and no fireworks are allowed!

13) Supply tank

R1234yf exhaust valve

R134a exhaust valve

GM-820A-Dual A/C SYSTEM MAINTENANCE CENTRE-DUAL

18

A. If the refrigerant amount in the main tank is less 3kg, the flushing function can’t run any more, and if

less 1kg, the recharging function also can’t run any more, until supply enough refrigerant into the

machine.

B. Operations:

B-1: Power on, select refrigerant type, then select Supply Tank function.

B-2: Select if use the supplying connecter:

B-3.1: If use the supplying connecter, the pipeline connection is as follows:

Fitting the supplying connecter to the port of fresh refrigerant tank.

Note: it should connect to the liquid port of fresh refrigerant tank. If has no liquid port,

please place the fresh refrigerant tank upside down.

Connect the HP coupler to the supplying connecter and open it.

B-3.2: If don’t use the supplying connecter, the pipeline connection is as follows:

Connect the port of fresh refrigerant tank to the LP port of equipment.

Note: it should connect to the liquid port of fresh refrigerant tank. If has no liquid port,

please place the fresh refrigerant tank upside down.

B-4: Open the valve of fresh refrigerant tank.

B-5: Set the supplying amount and press ENTER key to run.

Note: Amount of supplying:Setting the amount according to remain amount in the tank.

Suggestion: supplying amount = (4.5~5) - remained amount.

B-6: When alarming, please close the valve of the fresh refrigerant tank, upright it and press ENTER

key to confirm.

B-7: After the refrigerant in the pipeline is recovered, the equipment stops automatically. Then install

the quick coupling.

Special declare:

When the refrigerant is supply to the new equipment, due to the vacuum state of equipment system, some

refrigerant will remain in the pipeline and components when supplying refrigerant to tank, resulting in the

actual amount of refrigerant recovered will be more than that shown by the equipment, which is normal.

14) System function

14-1) Language

Change the language

GM-820A-Dual A/C SYSTEM MAINTENANCE CENTRE-DUAL

19

14-2) Units

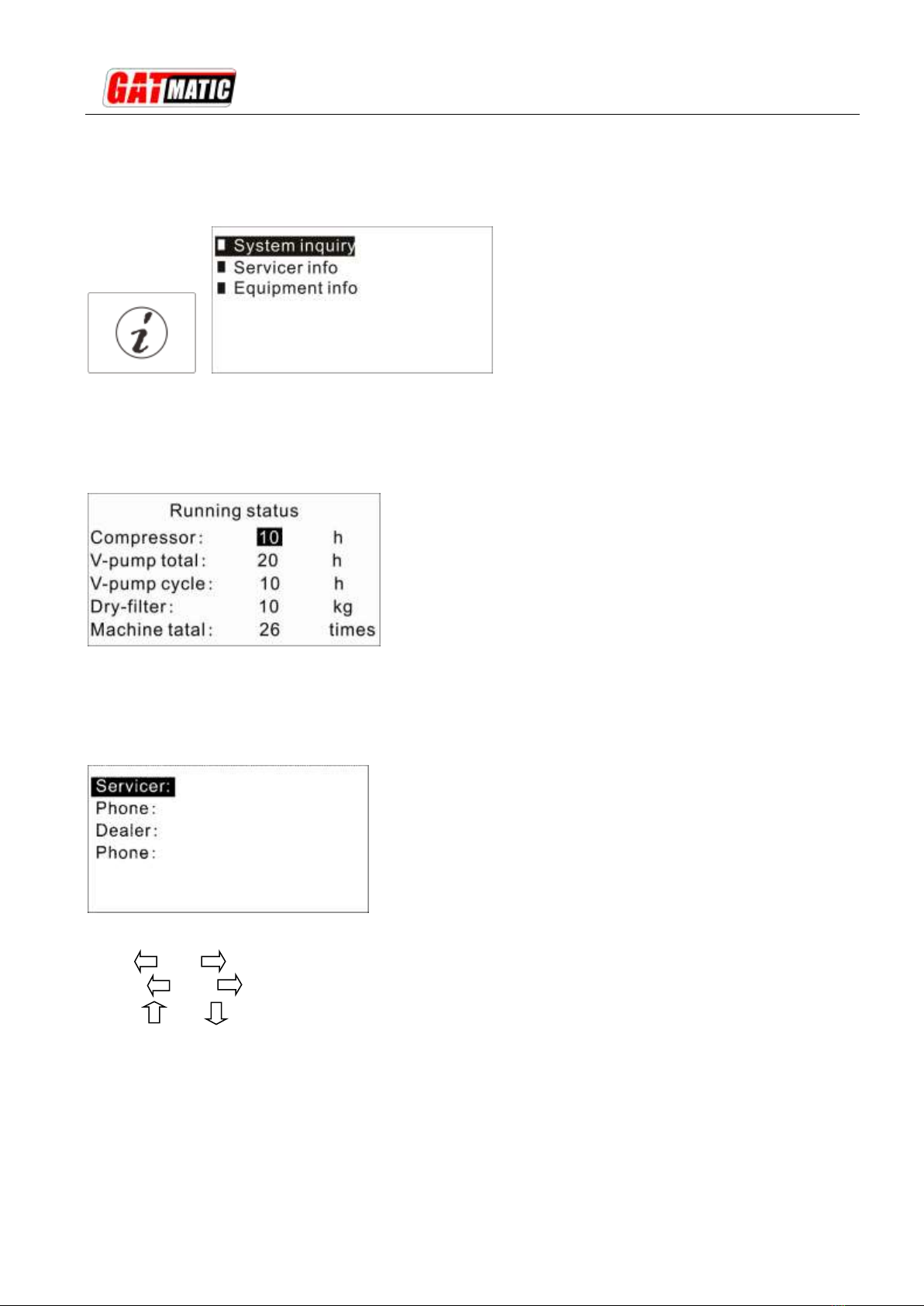

15) Equipment info

15-1) System inquiry

Here you can check the working status of the machine.

15-2) Servicer info

Here you can set and check the servicer and dealer information.

The way for setting:

Press and keys at same time into the setup state.

Use the and keys to select position

Use the and keys to set the content.

15-3) Equipment info

Here you can check the SN, hardware version, software version etc.

GM-820A-Dual A/C SYSTEM MAINTENANCE CENTRE-DUAL

20

16) Help

Here you can check all of the help messages.

Declare:

We reserve the right to modify the contents of this document without prior notice to our customers.

This manual suits for next models

2

Table of contents

Other GAT Cleaning Equipment manuals