Safety

Page 1 - 1

F - 160 CE Operation and Maintenance Manual

© GBC Films Group April 2000

Section 1 Safety

CAUTION

Do not attempt to operate your Falcon 160

CE laminator until you have read this

section carefully!

Your safety, as well as the safety of others, is

important to GBC Films Group. This section contains

importantsafetyinformation.

Thefollowingsymbolsareusedthroughoutthis

manual to indicate Information,Caution, Warning,

Dangerand Electrical Shockconditions.

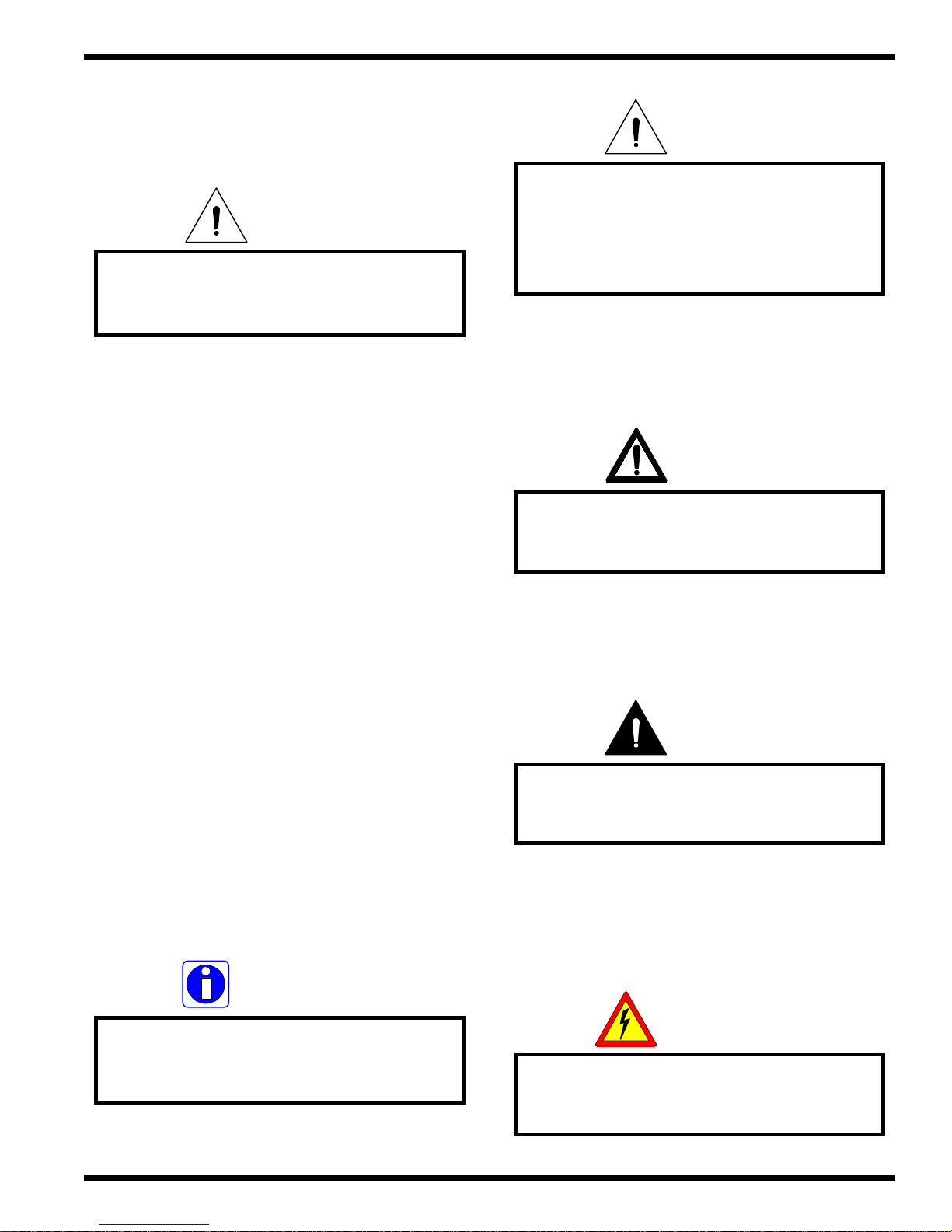

1.1 Symbols

INFORMATION

Indicates helpful information that should be

considered before, during, or after an

action, step or procedure is given.

CAUTION

Indicates a potentially hazardous situation

which, if not avoided, could result in minor

or moderate injury, or alerts against unsafe

practices or alerts against actions which

could damage the product.

WARNING

Indicates a potentially hazardous situation

which, if not avoided, could result in serious

injury.

DANGER

Indicates an imminently hazardous situation

which, if not avoided, could result in death

or serious injury.

ELECTRICAL

SHOCK

Indicates an electrical shock situation which,

if not avoided, could result in serious

paralyzation of the body or death.