1

31-10955 11-13 GE

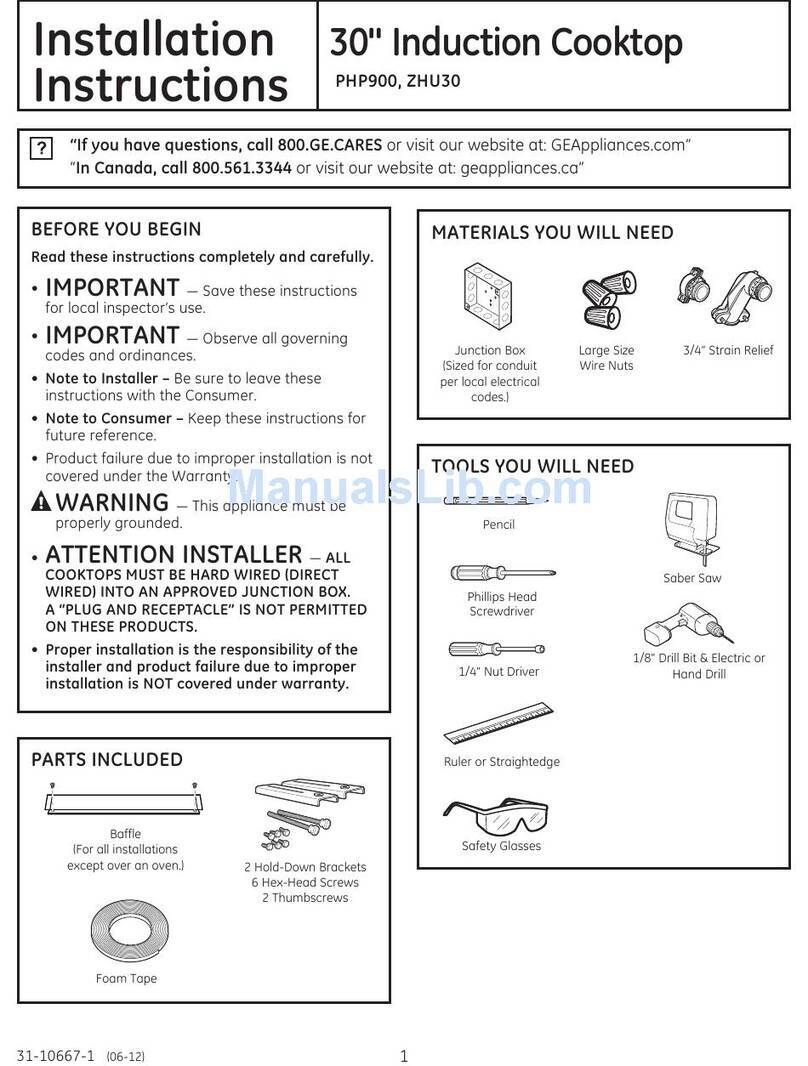

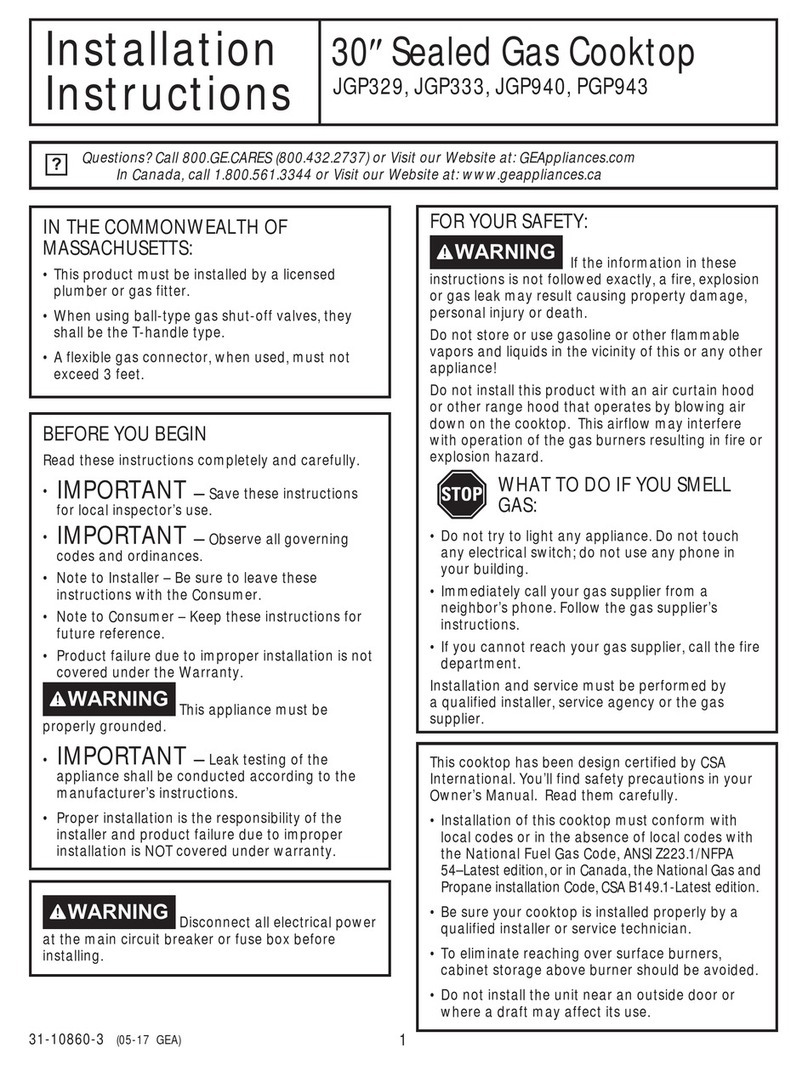

BEFORE YOU BEGIN

Read these instructions completely

and carefully.

•IMPORTANT ³Save these instructions

for local inspector’s use.

•IMPORTANT ³Observe all governing

codes and ordinances.

• Note to Installer – Be sure to leave these

instructions with the Consumer.

• Note to Consumer – Keep these instructions for

future reference.

• Product failure due to improper installation is not

covered under the Warranty.

WARNING ³This appliance must be

properly grounded.

•

IMPORTANT ³Leak testing of the

appliance shall be conducted according to the

manufacturer’s instructions.

• Proper installation is the responsibility of the

installer and product failure due to improper

installation is NOT covered under warranty.

IN THE COMMONWEALTH OF

MASSACHUSETTS:

• This product must be installed by a licensed

plumber or gas fitter.

• When using ball-type gas shut-off valves, they

shall be the T-handle type.

• A flexible gas connector, when used, must not

exceed 3 feet.

Questions? Call 800.GE.CARES (800.432.2737) or Visit our Website at: GEAppliances.com

In Canada, call 1.800.561.3344 or Visit our Website at: www.geappliances.ca

Installation

36sSealed Gas Cooktop

Instructions PGP976, PGP986, CGP650

FOR YOUR SAFETY:

WARNING ³If the information in this

manual is not followed exactly, a fire, explosion

or gas leak may result causing property damage,

personal injury or death.

Do not store or use gasoline or other flammable

vapors and liquids in the vicinity of this or any

other appliance!

Do not install this product with an air curtain

hood or other range hood that operates by

blowing air down on the cooktop. This airflow

may interfere with operation of the gas burners

resulting in fire or explosion hazard.

WHAT TO DO IF YOU SMELL

GAS:

• Do not try to light any appliance. Do not touch

any electrical switch; do not use any phone in

your building.

• Immediately call your gas supplier from a

neighbor’s phone. Follow the gas supplier’s

instructions.

• If you cannot reach your gas supplier, call the

fire department.

Installation and service must be performed by

a qualified installer, service agency or the gas

supplier.

This cooktop has been certified by UL. You’ll find

safety precautions in your Owner’s Manual. Read

them carefully.

• Installation of this cooktop must conform with

local codes or in the absence of local codes with

the National Fuel Gas Code, ANSI Z223.1/NFPA

54–Latest edition.

• Be sure your cooktop is installed properly by a

qualified installer or service technician.

• To eliminate reaching over surface burners,

cabinet storage above burner should be avoided.

• Do not install the unit near an outside door or

where a draft may affect its use.

WARNING ³Disconnect all electrical

power at the main circuit breaker

or fuse box before installing.