– 3 –

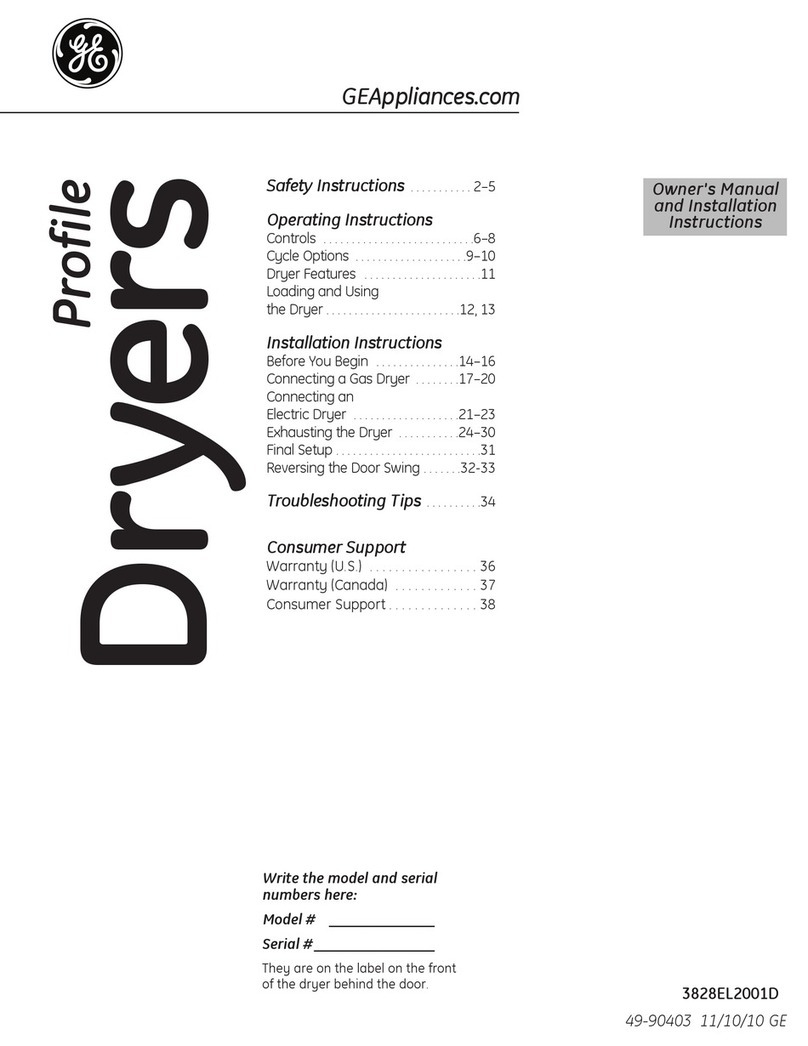

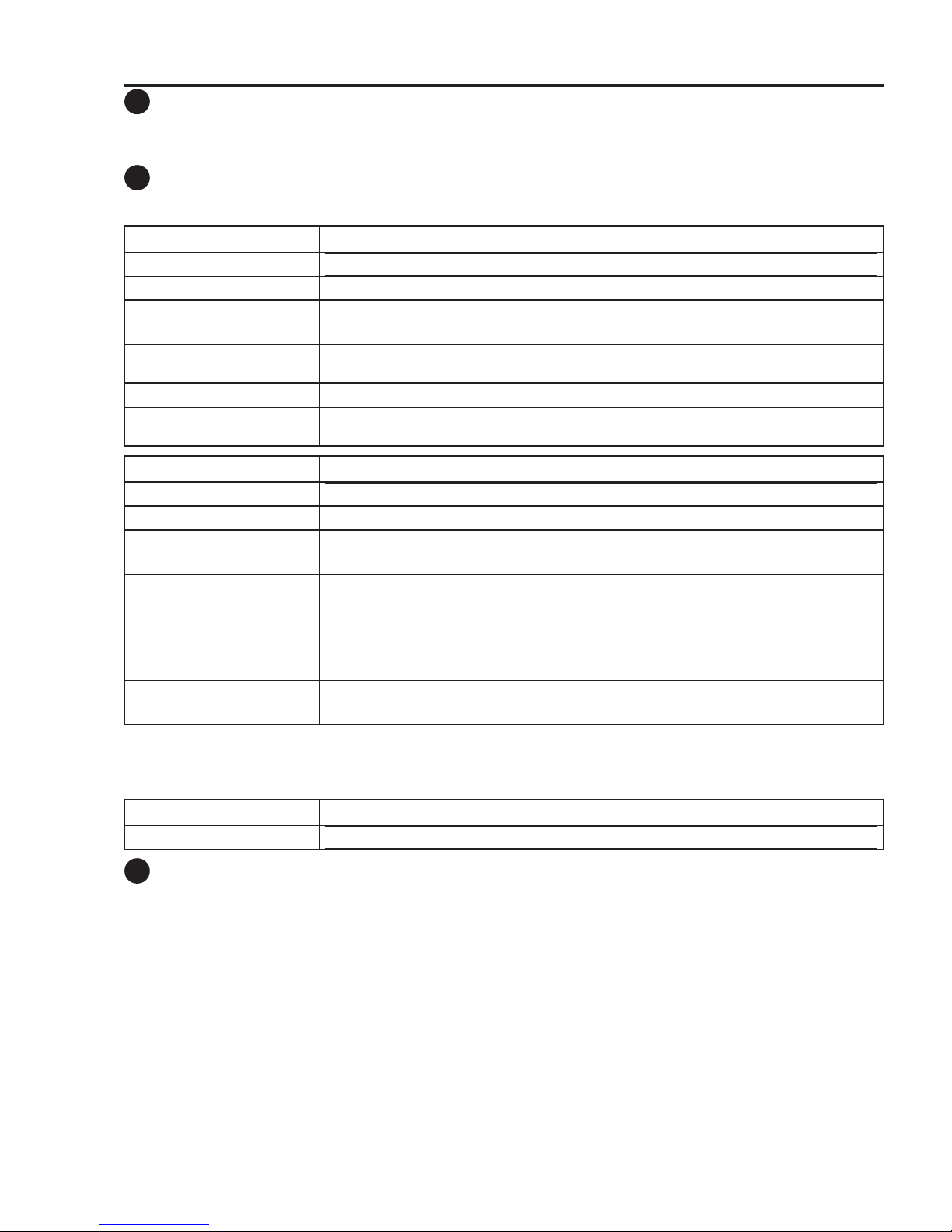

Table of Contents

Air Duct Assembly ............................................................................................................................................................29

Airflow ....................................................................................................................................................................................22

Belt Switch............................................................................................................................................................................36

Blower Housing..................................................................................................................................................................37

Burner Assembly and LP Conversion......................................................................................................................38

Component Locator Views...........................................................................................................................................24

Control Board Connector Locator View .................................................................................................................26

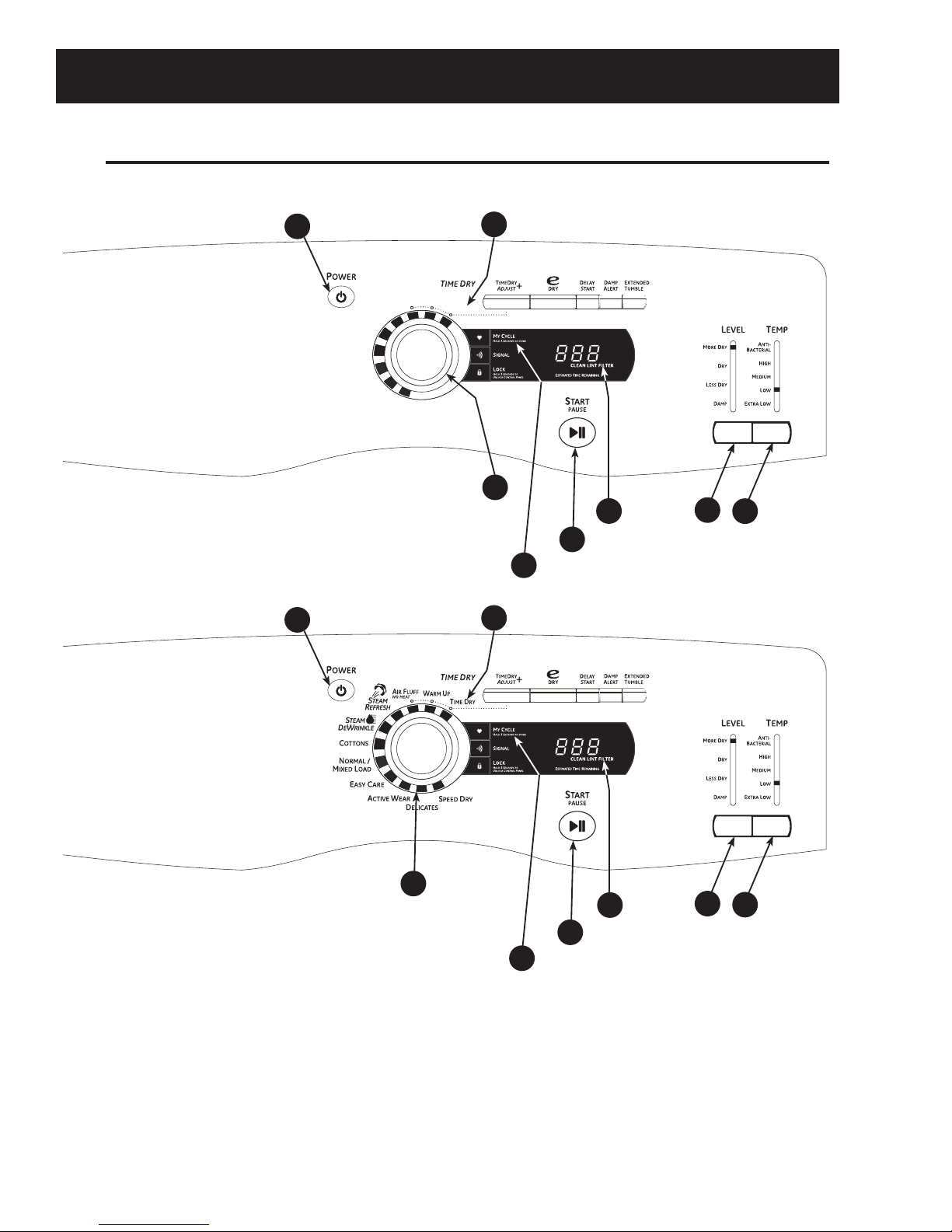

Control Features............................................................................................................................................................... 8

Control Panel.......................................................................................................................................................................27

Cycle Matrix Chart............................................................................................................................................................23

Demo Mode.........................................................................................................................................................................46

Door Switch ......................................................................................................................................................................... 31

Drive Belt...............................................................................................................................................................................32

Drum.......................................................................................................................................................................................33

Drum Light Receptacle...................................................................................................................................................30

Drum Shaft and Bearing................................................................................................................................................33

Drum Slide Assembly......................................................................................................................................................29

Dryer Components...........................................................................................................................................................27

Electronic Control ............................................................................................................................................................45

Flame Detector ..................................................................................................................................................................40

Front Panel...........................................................................................................................................................................28

Gas Valve..............................................................................................................................................................................39

Gas Valve Coils...................................................................................................................................................................38

Heater Assembly...............................................................................................................................................................37

High Limit Thermostat....................................................................................................................................................44

Idler Assembly....................................................................................................................................................................33

Ignitor.....................................................................................................................................................................................40

Ignitor Circuit Operation................................................................................................................................................41

Inlet Control Thermistor.................................................................................................................................................42

Inlet Safety Thermostat.................................................................................................................................................42

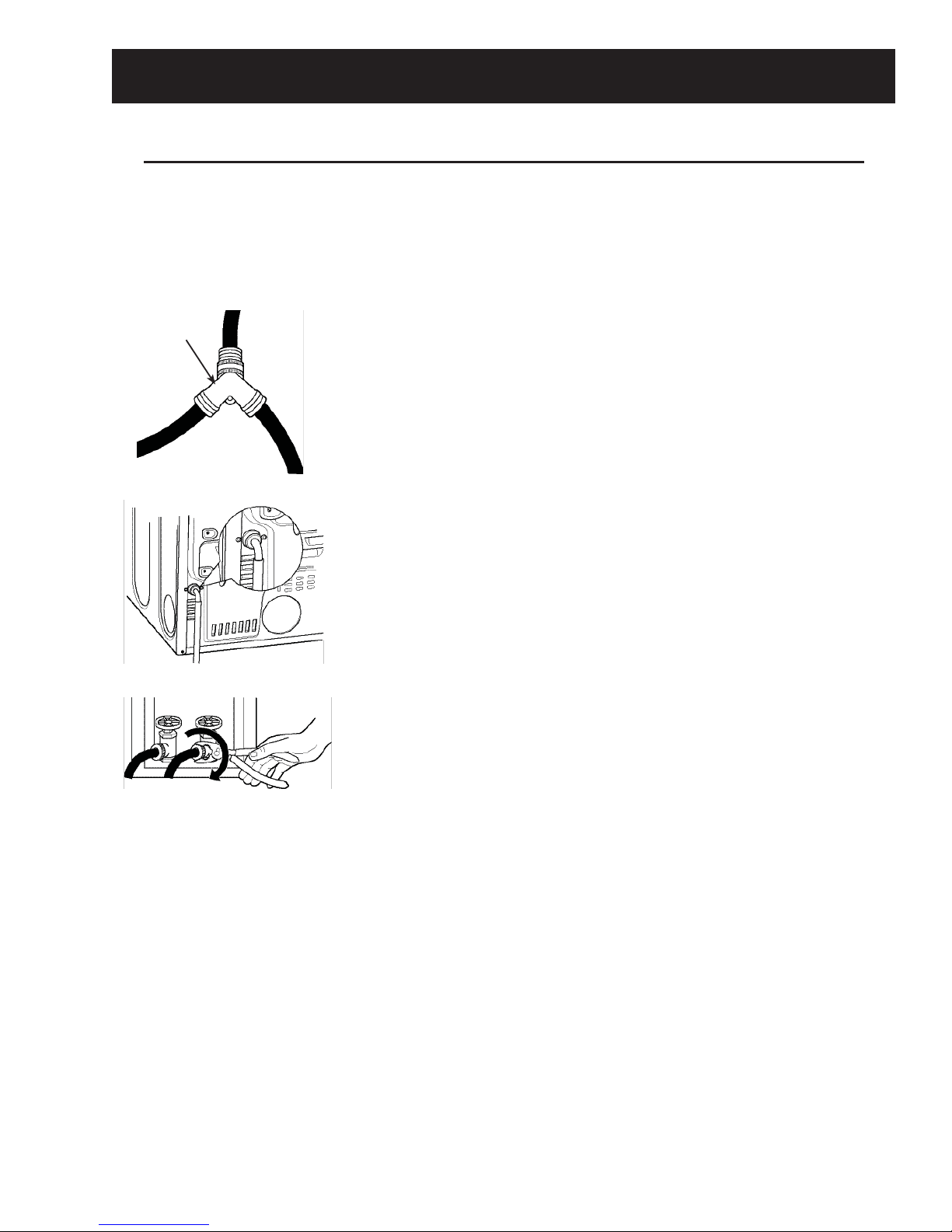

Introduction......................................................................................................................................................................... 5

Moisture Sensor ................................................................................................................................................................31

Motor and Blower Wheel...............................................................................................................................................34

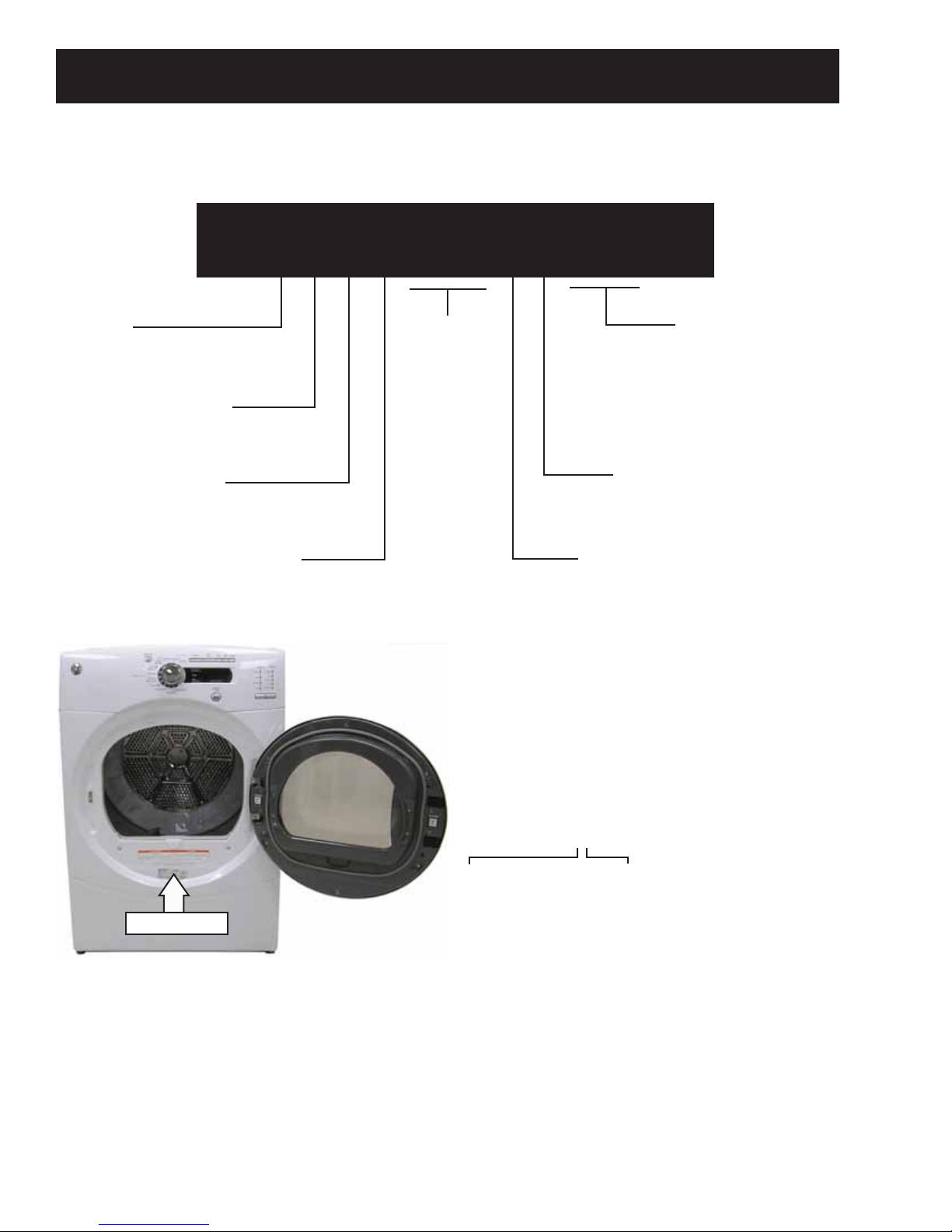

Nomenclature .................................................................................................................................................................... 6

Operation Overview.........................................................................................................................................................21

(Continued Next Page)