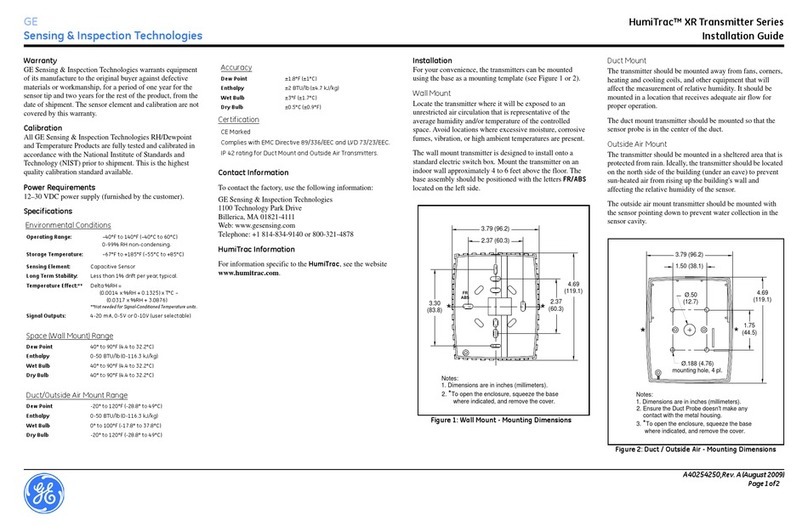

GE HygroPro User manual

Other GE Transmitter manuals

GE

GE DewPro MMY30 User manual

GE

GE Masoneilan 12420 Installation and operating manual

GE

GE DewPro MMY31 User manual

GE

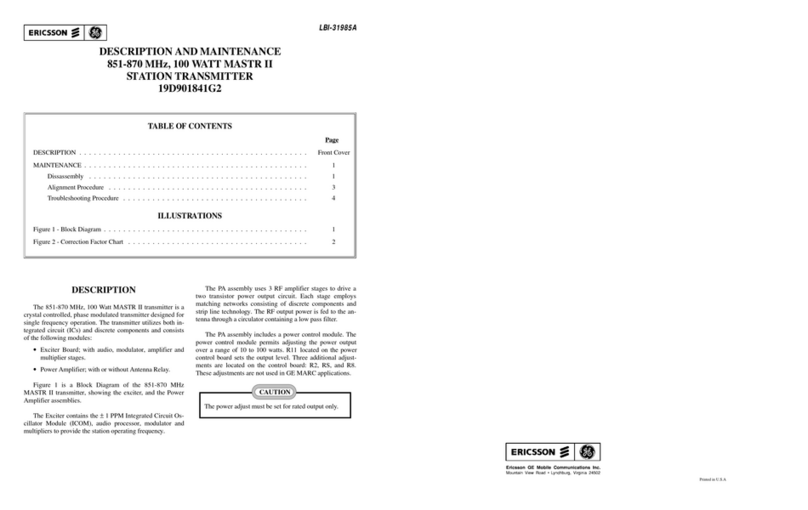

GE BC-375-E User manual

GE

GE XGS868 Owner's manual

GE

GE VT6010 Installation instructions

GE

GE 97651 User manual

GE

GE XMO2 User manual

GE

GE HygroTrace User manual

GE

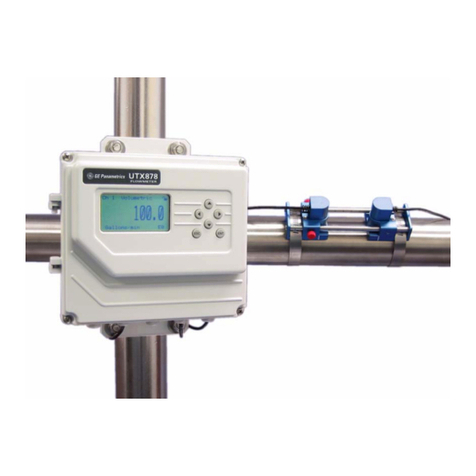

GE UTX878 Ultrasonic User manual

Popular Transmitter manuals by other brands

Dejero

Dejero EnGo 3x manual

Rosemount

Rosemount 4600 Reference manual

Speaka Professional

Speaka Professional 2342740 operating instructions

trubomat

trubomat GAB 1000 instruction manual

Teledyne Analytical Instruments

Teledyne Analytical Instruments LXT-380 instructions

Rondish

Rondish UT-11 quick start guide