6 - EN © Copyright by GEDORE Automotive GmbH, Germany

0500-45KAe200201.indd

Operating instructions

(Translation of the operating instructions)

EN

2. Product description

2.1 KL-0500-45 KA - SAC clutch tool set in plastic case

Fits universally for almost all SAC clutches with 3- and 4-hole pitch available on the market. Installed, for example, in

VW-Audi, BMW, Mercedes, Volvo, Opel, Renault etc.

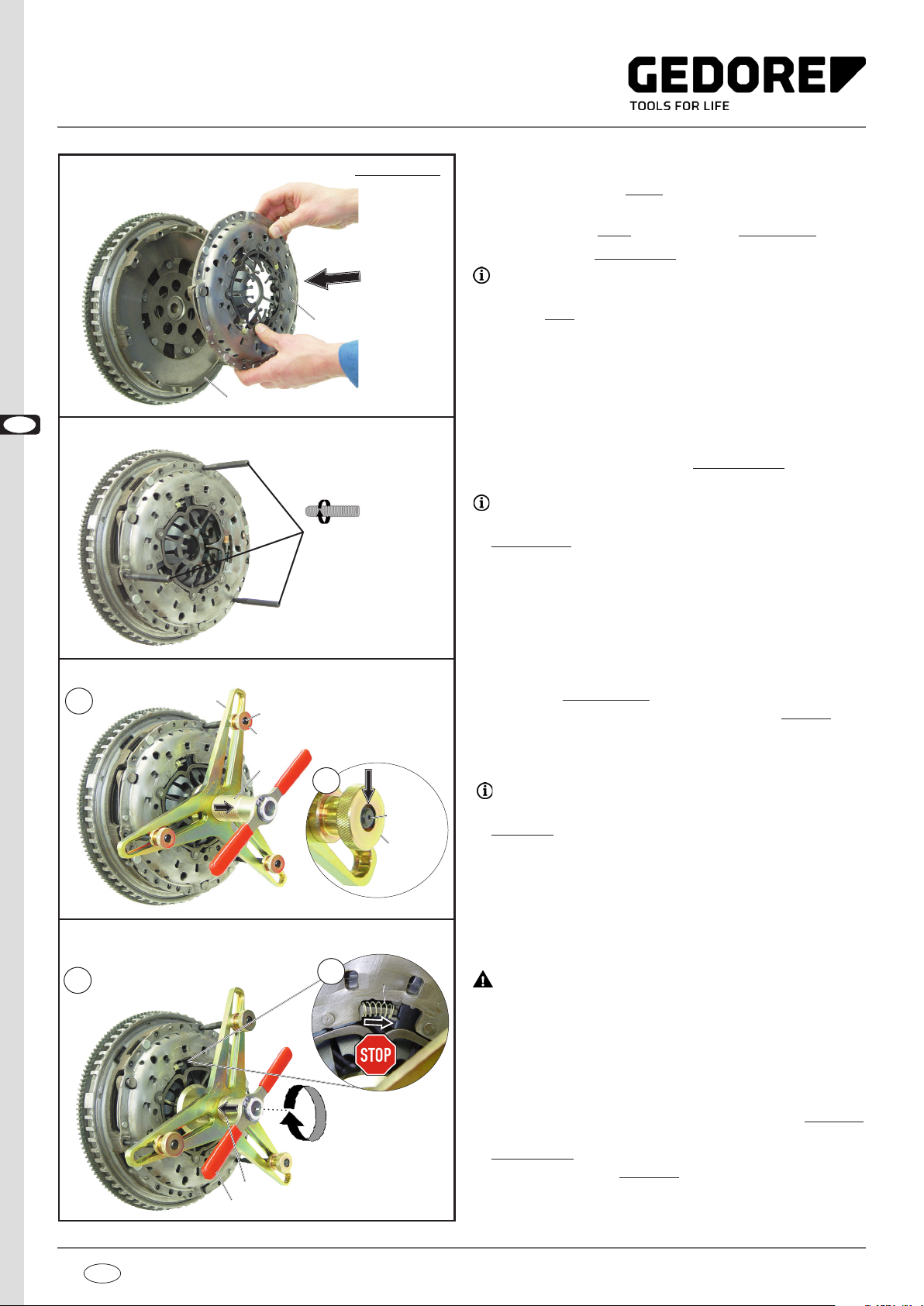

This SAC clutch tool kit is absolutely necessary for professional and damage-free removal and installation of SAC clutches (Self-

Adjusting Clutch). It also permits the SAC adjusting ring in the clutch pressure plate to be reset.

The clutch centring tool included in the scope of delivery permits clutch discs with a hub Ø of 15 - 28 mm and a guide bearing or

crankshaft bore Ø of 12 - 28 mm to be centred. Vehicles without guide bearings in the crankshaft are not a problem either.

The two clamping / centring elements ensure precise centring in the clutch disc on the rst clamping element, and precise

centring in the guide bearing or crankshaft hole on the second clamping element. Even clutches with a crankshaft bore diameter

exceeding the clutch hub diameter can be centred neatly and precisely.

2.2 Scope of delivery/spare parts:

KL-0500-45 KA - SAC clutch tool set

Item Part no. Description Qty

1KL-0500-401-1 Clutch pretensioning device 1

1.1 KL-0500-4002 Spindle 1

1.2 KL-0032-0012 Retaining ring A28 1

1.3 KL-0500-4003 Toggle with protective handle 1

1.4 KL-0500-4005 Thrust piece 1

1.5 KL-0500-4001 Base plate(3-hole pitch) 1

- KL-0500-1007 Steel ball set 1

- KL-0500-1008 Spring ring A24 1

2 KL-0500-4006 Knurled nut 4

3 KL-0500-4007 Threaded pin M6 4

4 KL-0500-4008 Threaded pin M7 4

5KL-0500-4009 Threaded pin M8 4

6KL-0500-4011 Base plate(4-hole pitch) 1

7 KL-0500-405 Clutch centring tool 1

7.1 KL-0500-4053 Clamping segment set Ø 15.5mm 1

7.2 KL-0500-4055 Cone attachment 1

7.3 KL-0500-4054 Clamping segment set Ø 20mm 1

7.4 KL-0069-0005 Clamping cone size 1, 15mm 1

7.5 KL-0069-0006 Clamping cone size 2, 22mm 1

7.6 KL-0500-4051 Base body pipe 1

7.7 KL-0500-4103 Knurled nut 1

7.8 KL-0500-4052 Clamping crew 1

7.9 KL-0500-4057-1 Centring mandrel Ø 12mm 1

7.10 KL-0500-4057-2 Centring mandrel Ø 14mm 1

7.11 KL-0500-4057-3 Centring mandrel Ø 15mm 1

7.12 KL-0500-4056-1

Sliding cone Ø 15mm, 30 m

1

7.13 KL-0500-4056-2

Sliding cone Ø 15mm, 40mm

1

7.14 KL-0500-4056-3

Sliding cone Ø 15mm, 67mm

1

7.15 KL-0500-4056-4

Sliding cone Ø 15mm, 75mm

1

7.16 KL-0500-4056-5

Sliding cone Ø 18mm, 67mm

1

7.17 KL-0500-4056-6

Sliding cone Ø 18mm, 75mm

1

8 KL-0500-11

Clutch centring mandrel Ø 23mm

1

9 KL-0500-12 Clutch centring mandrel Ø 28mm 1

10 KL-0500-21

Clutch centring mandrel Ø 32.5mm

1

11 KL-0500-403 Reset tool 1

- KL-0500-4590 Plastic case 1

2.3 Specications:

Weight: ................................................................................................7.0kg

1

1.5

For 4-hole pitch

1.3

1.1

2 2 2 3 3 3 4 4 4 5 5 5

7

7.9 7.14

7.12

7.15

7.16

7.17

7.10

7.11

7.8

7.2 7.3 7.5

7.7

7.6

7.4

7.1

8

11

9

10

3 4 5

2

6

1.4

1.2

7.13