6

Chapter 4

0041-44Ce160604.docx hu-gm © Copyright by GEDORE Automotive GmbH, Germany

Instruction Manual

2. Product Description

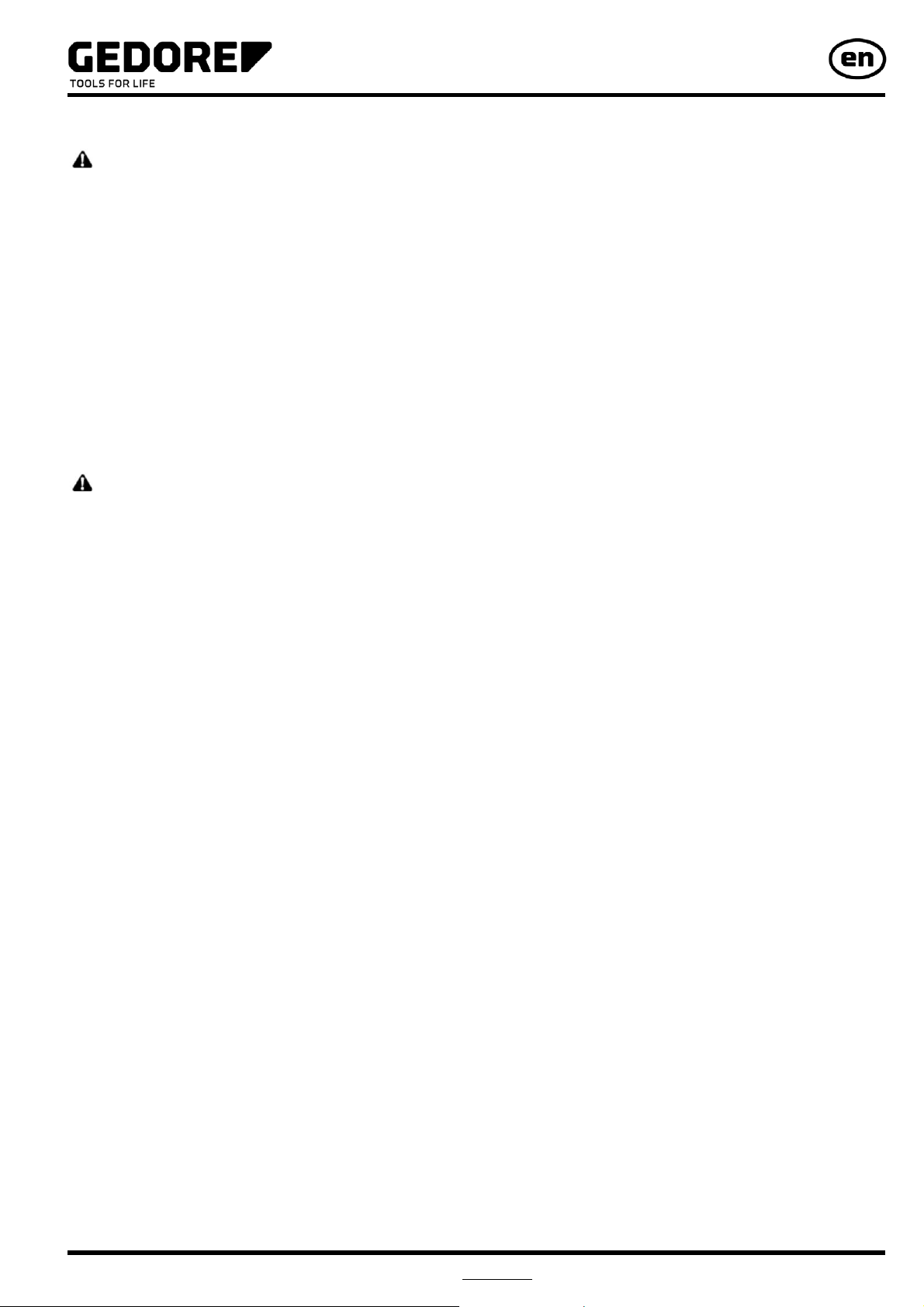

2.1 KL-0041-44 C - Wheel Bearing Tool

with 17t Hydraulic Cylinder (Pat.)

Suitable for use on vehicles with bearing Ø of 72mm (both

with and without snap ring [such as SKF bearings]); e.g.

Audi A2 (from 2000 onwards), Seat Ibiza (from 2002

onwards), Škoda Fabia (from 2000 onwards) and VW Polo

(from 2002 onwards), Fox, etc.

The KL-0041-44 Cwheel bearing tool enables the quick and

safe installation of wheel hub bearing units without the risk of

damaging them.

Due to the particular design of the wheel hub bearing units,

conventional installation by means of a thrust piece under a

workshop press or by using standard wheel bearing tools is no

longer feasible. This is because, with this type of bearing, the

outer bearing race is covered by the wheel hub. GEDORE

Automotive have now come up with a solution to this problem

with the specifically designed clamping shells which are

mounted against the wheel bearing outer race behind the wheel

hub, thus allowing for professional installation of the wheel hub

bearing units.

The clamping shells feature a securing collar designed to ensure

that wheel hub bearing units without snap ring are pressed in

completely/into deepened position.

For the removal of wheel hub bearing units, the wheel hub puller

KL-0041-38 is needed.

2.2 Scope of Delivery:

Pos. Part No. Description Qty

1 KL-0040-2500 Hydraulic Cylinder (17t) 1

2 KL-0040-3009 Clamping Nut, M20 1

3 KL-0039-1920-1 Pull Spindle, M20 1

4 KL-0039-1002 Retaining Adaptorwith O-Rings,

for Clamping Nut and Pressure Spindle 1

5 KL-0039-1003 Retaining Adaptor with O-Rings, for

Hydraulic Cylinder 1

6 KL-0041-4400 C Clamping Shells (Pair), Ø 72mm 1

7 KL-0041-3931 Pressure Screw, M14x1.5 5

8 KL-0039-1802 CentringSleeve, long, Ø 27.4mm 1

9 KL-0039-1265 Pressure Ring, Ø 65mm 1

10 KL-0039-1674 Pressure-/Support Sleeve, short, Ø 74mm 1

2.3 Technical Data

Maximum load capacity of the pull spindle: ......................... 20t

Maximum load capacity of the hydraulic cylinder:................ 17t

Weight: .......................................................................... 15.8kg

3. Preparatory Work

Before the first commissioning of the wheel bearing tool, check

and confirm you have all the parts listed in the scope of delivery.

Then, read and follow the mounting instructions.

3.1 Checking the Delivery.

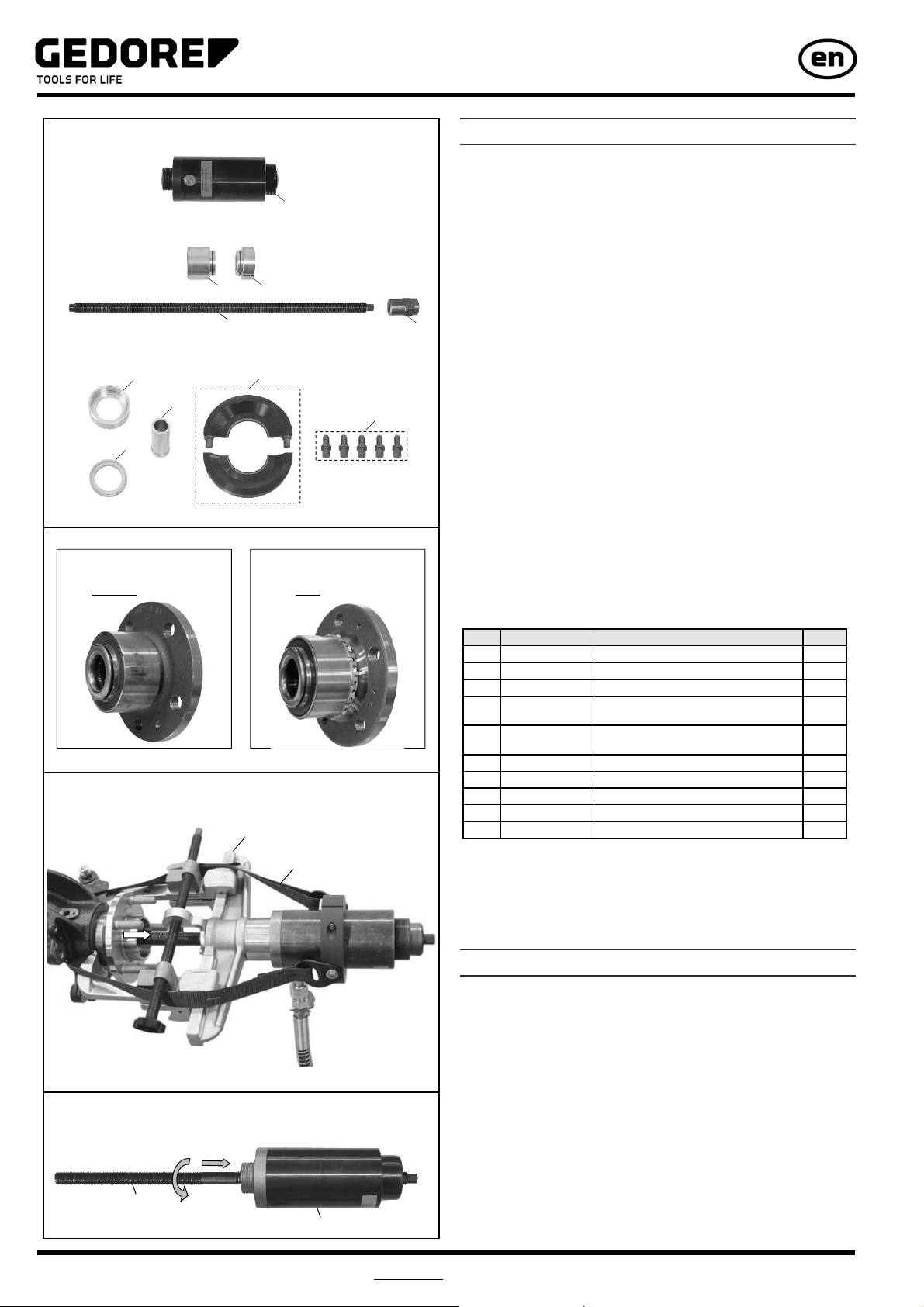

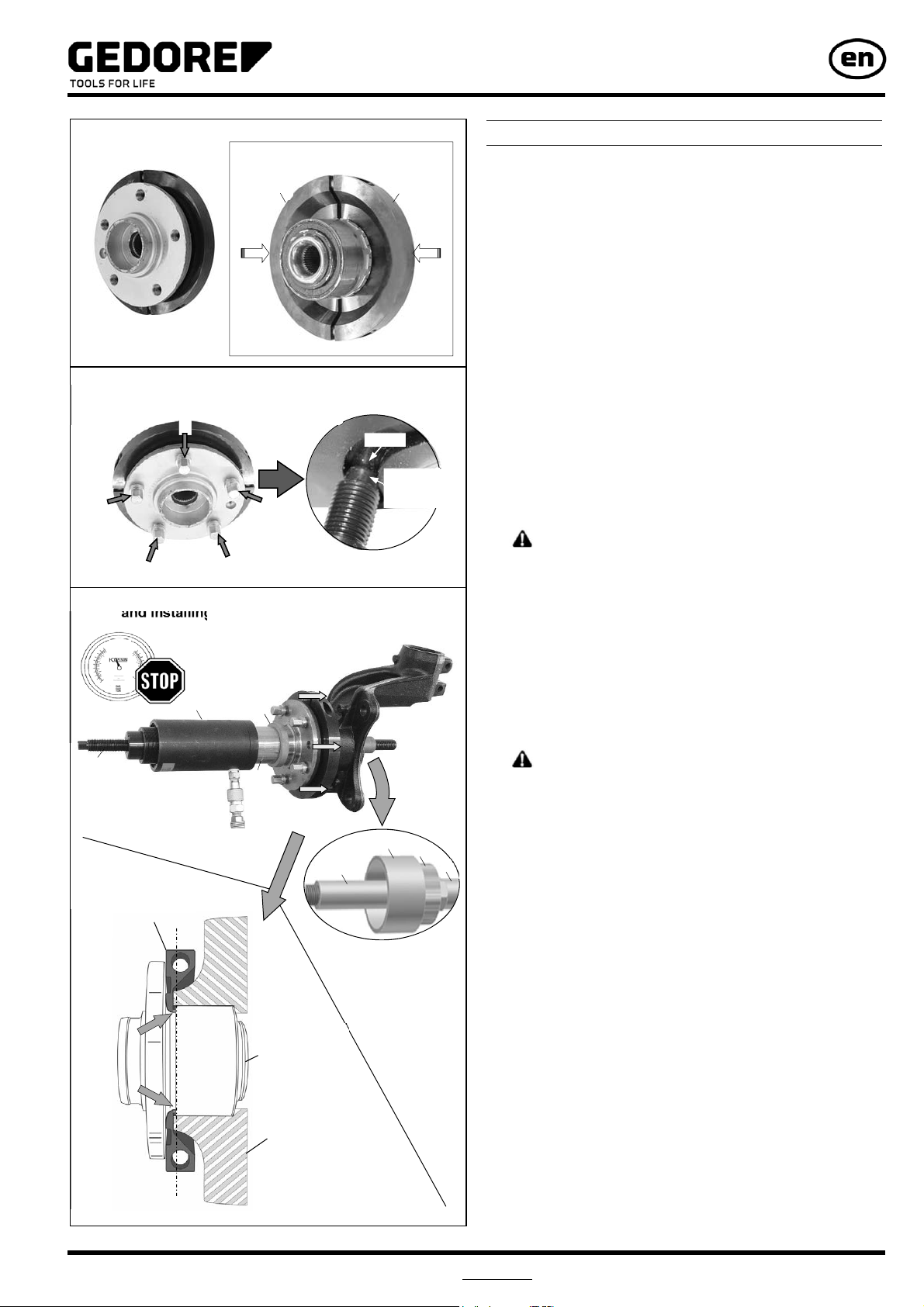

3.2 Preparing the Vehicle.

1. Loosen and/or remove components as necessary.

Remove wheel hub bearing unit using the KL004138 wheel

hub puller (accessory). (Fig. 1)

Note: Secure tool with safety belt KL-0040-2590

(accessory) to prevent it from falling.

3.3 Preparing the Tool.

1. Screw pull spindle “3“ into hydraulic cylinder “1“. (Fig. 2)

KL-0041-44 C

Wheel Hub Bearing Unit:

Fig. 1: Removing the wheel hub bearing unit.

Fig. 2: Screwing the pull spindle into hydraulic cylinder.

KL-0041-38 (accessory)

KL-0040-2590 (accessory)

1

3

10

9

8

7

1

6

3 2

5 4

Wheel hub bearing unit

without snap ring

Wheel hub bearing unit

with snap ring