7

Chapter 3 0145-120Ae170116.docx hu-gm

© Copyright by GEDORE Automotive GmbH, Germany

Instruction Manual

4. Example of Use:

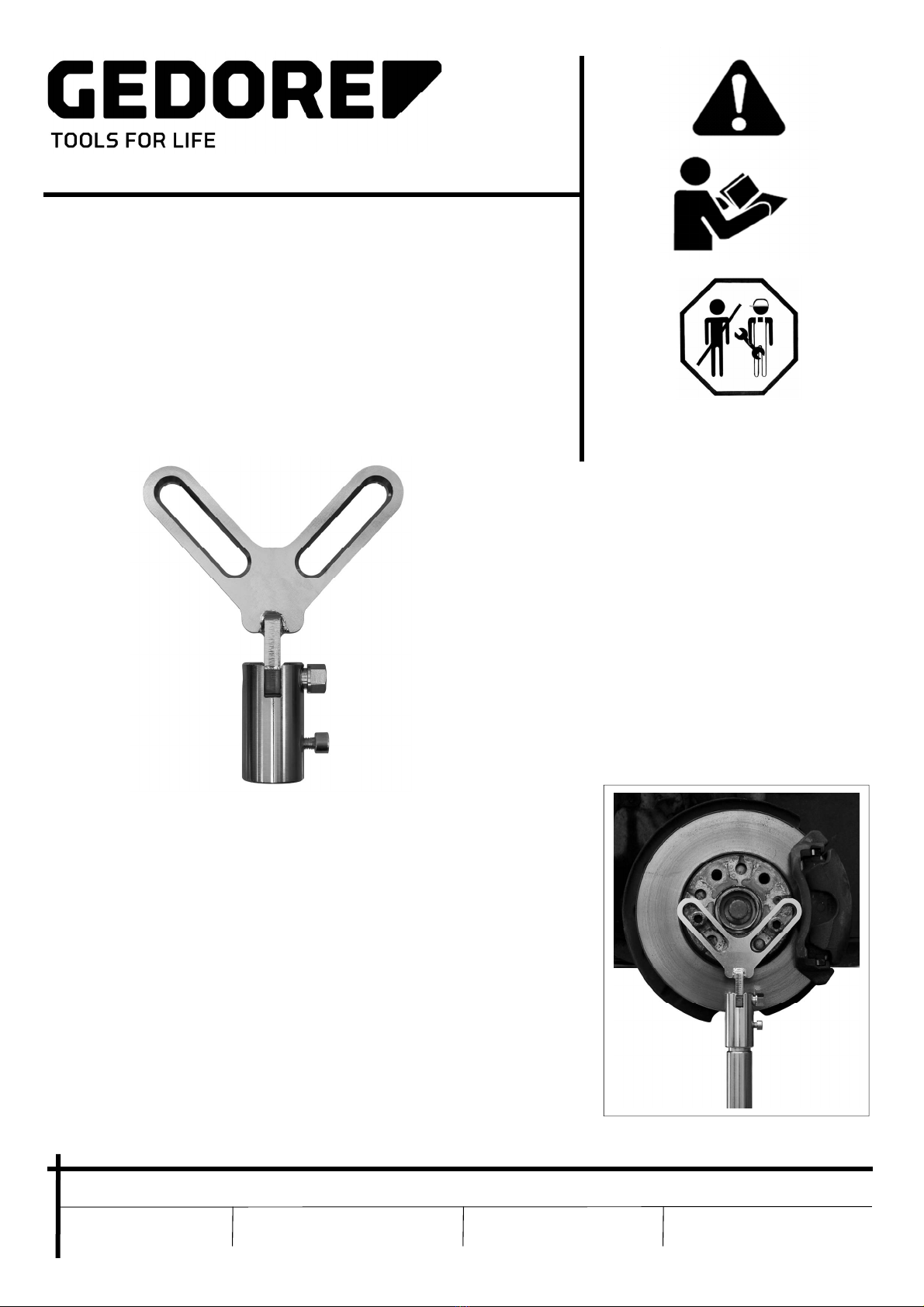

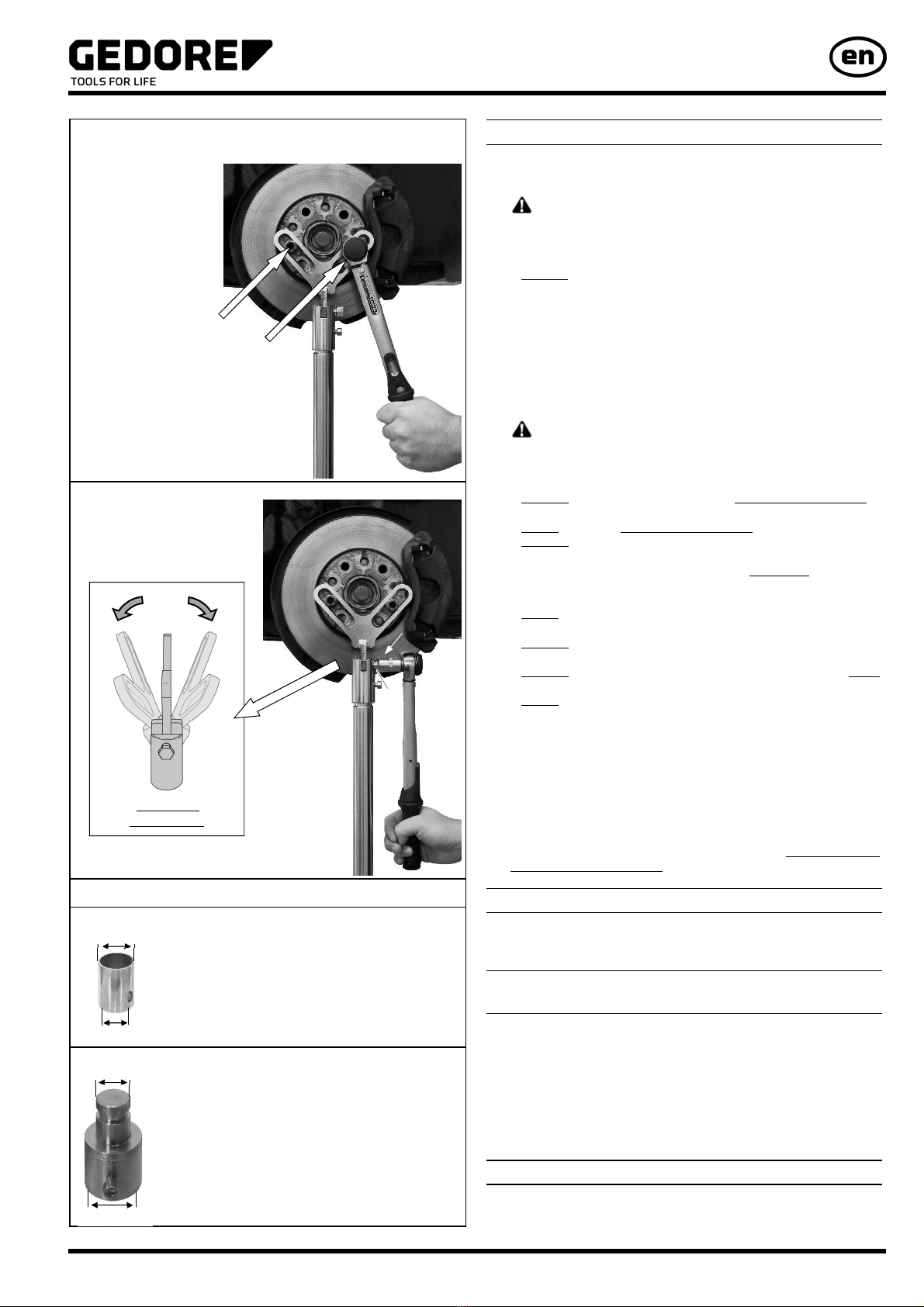

The following instructions describe how to support and secure a control arm at

the front axle with the aid of the supporting device for control arm in

conjunction with an appropriate transmission jack.

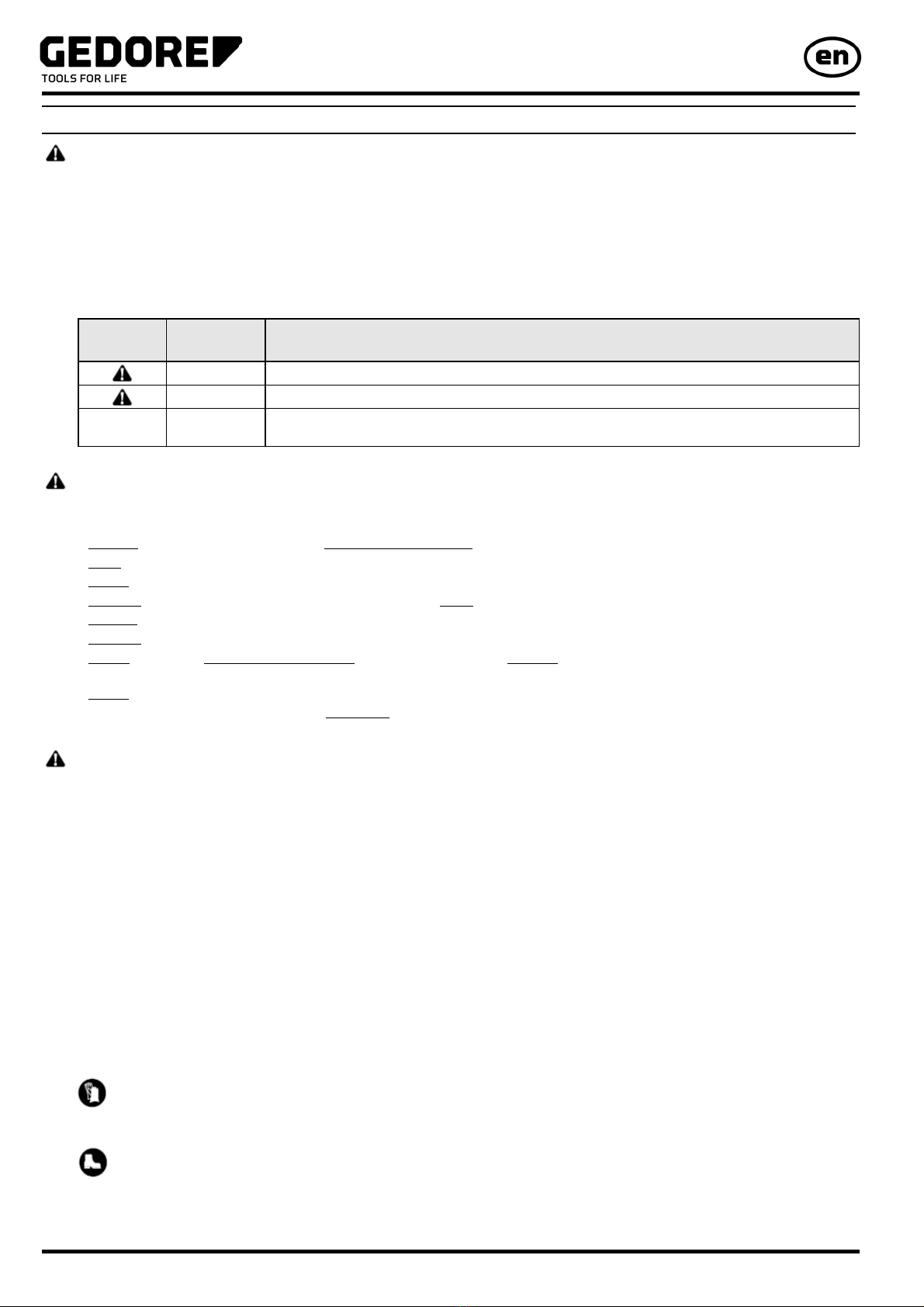

1.

DANGER

When raising axle components, high forces come into play. As a result,

there is a risk of the supporting device for control arm breaking and falling

to pieces. This will lead to parts becoming projectiles.

ALWAYS ensure that the supporting device for control arm is secured to

the wheel hub with either 2x wheel bolts or lug nuts as appropriate.

Bolt supporting device for control arm and wheel hub together using

2x wheel bolts or lug nuts as shown in Fig.

2.

Note: Tighten wheel bolts or lug nuts to 10Nm.

2. Fix supporting device for control arm at camber angle position.

To do this, tighten clamp screw “2“ as shown in Fig.

3.

Notes: Tighten clamp screw “2“ to 25 Nm.

3. DANGER

When raising axle components, high forces come into play. As a result,

there is a risk of the supporting device for control arm breaking and falling

to pieces. This will lead to parts becoming projectiles.

ALWAYS observe and do not exceed the maximum load capacity of

the supporting device for control arm!

NEVER exceed the maximum load capacity of the transmission jack.

ALWAYS consult and adhere to the safety regulations and

specifications of the respective transmission jack!

The supporting device for control arm must only be used in

conjunction with a transmission jack that has been approved in

accordance with the Machinery Directive 2006/42/EC.

NEVER raise/lower a vehicle by means of a car lift when working with

the supporting device for control arm.

ALWAYS ensure that the supporting device for control arm is

protected from damage due to external force such as hammer blows.

ALWAYS check the supporting device for control arm prior to EACH

use to ensure that it is in good order and condition.

NEVER use the supporting device for control arm for raising vehicles!

ONLY use the original spare parts from GEDORE Automotive.

ATTENTION

Risk of damage to vehicle and supporting device for control arm.

Any work on vehicles should only be performed by qualified specialist

personnel observing and complying with the directions, provisions, and

safety regulations specified by the vehicle manufacturer.

Always refer to the vehicle manufacturer’s data and instructions as only

these apply to all work that is carried out on the vehicle.

Carry out repair/maintenance work on the vehicle according to the

manufacturer’s instructions.

6. Care and Storage

ATTENTION Always clean all parts after their use with a clean cloth only. In

order to protect against corrosion, lightly lubricate all metal parts after their use

with oil and store them in a clean and dry place.

7. Maintenance and Repair by

the GEDORE Automotive Service Centre.

For safety reasons, as soon as damage is noticed on the supporting device

for control arm, immediate steps must be taken to prevent it from being

used. For professional inspection and repair of the supporting device for

control arm, please contact the GEDORE Automotive Service Centre.

Address: GEDORE Automotive GmbH

Breslauerstraße 41 // 78166 Donaueschingen

Phone: 0771 83 22 371 / Email: info@gedore-automotive.com

For additional information concerning the use of our supporting device for

control arm, please contact the GEDORE Automotive Service Centre.

8. Environmentally Safe Disposal

Recycle/dispose of the supporting device for control arm and its packaging

material in compliance with the legal rules and regulations in force.

Fig. 2: Bolt supporting device for control arm

and wheel hub together.

Fig. 3: Fix supporting device at camber angle position.

5. Accessories:

KL-0040-2571 Adaptor Sleeve, Ø 25mm

KL-0040-2588 - Adaptor Sleeve, VW, Ø 36 mm

Ø 30mm

Ø 25mm

Adjustable

camber angle

Ø 36mm

Ø 30mm

This adaptor is needed to use the KL-0145-120A

supporting device for control arm in conjunction with a

transmission jack having a plunger with Ø of 25mm.

This adaptor is needed to use the retaining device

KL-0040-258 or the supporting device KL-0145-120 A

in conjunction with the VW Transmission Jack.

Tighten wheel bolts

or lug nuts to 10Nm.

+/- 45°

2

25 Nm