Rev. 00 02/21

4

Table of contents OptiCenter OC09

Sieve machine PS07-1**......................................................................... 24

Displacer**............................................................................................... 25

Powder feed to guns**............................................................................. 25

Level sensor** ......................................................................................... 25

Principle of operation............................................................................... 26

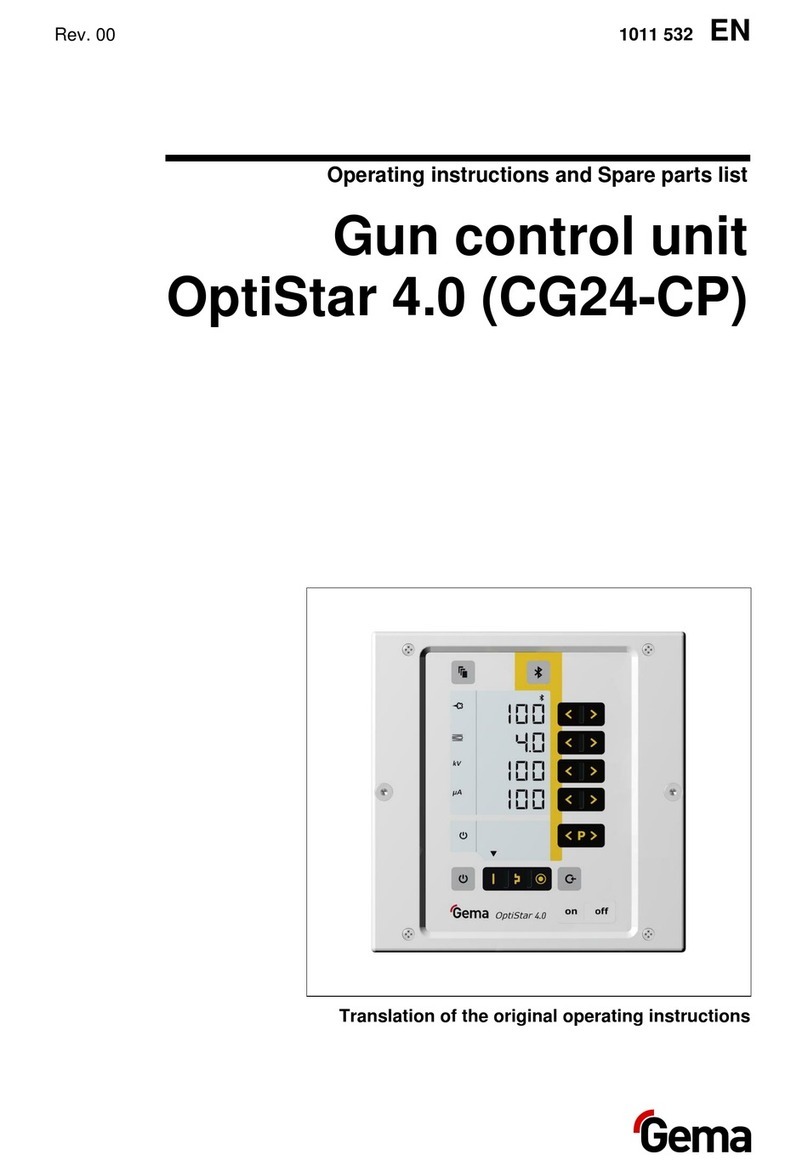

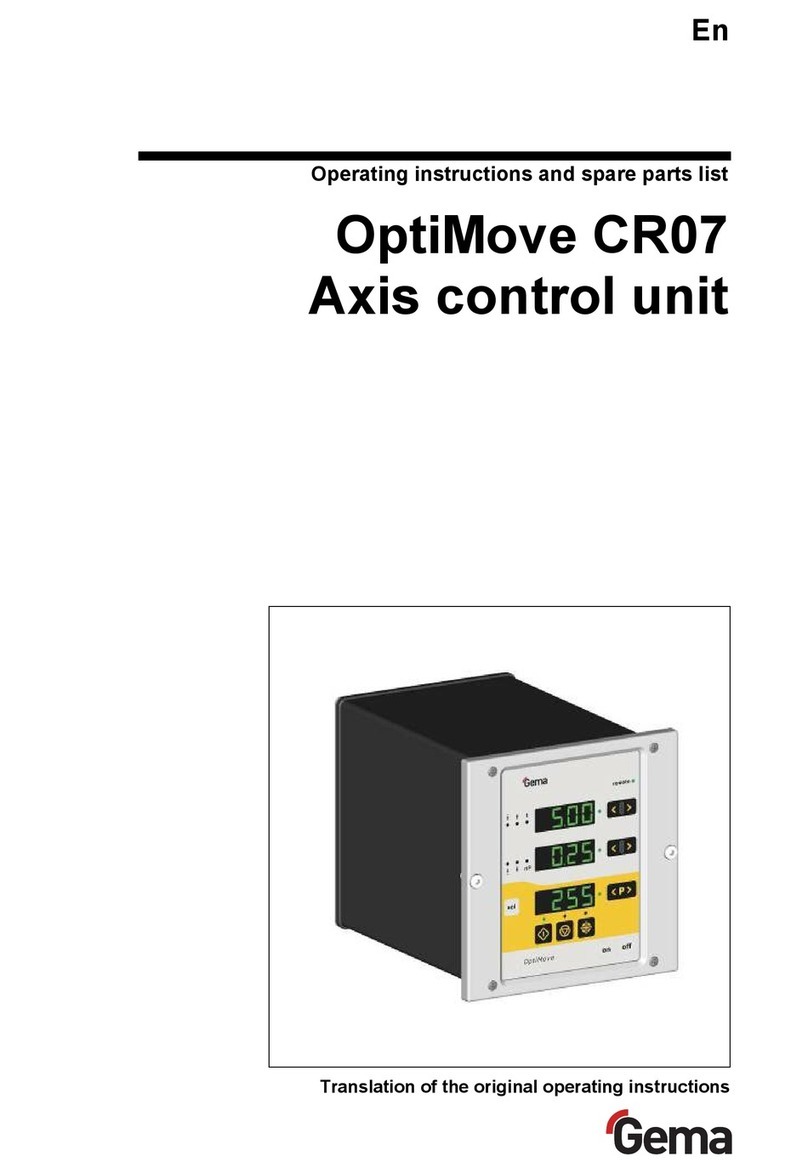

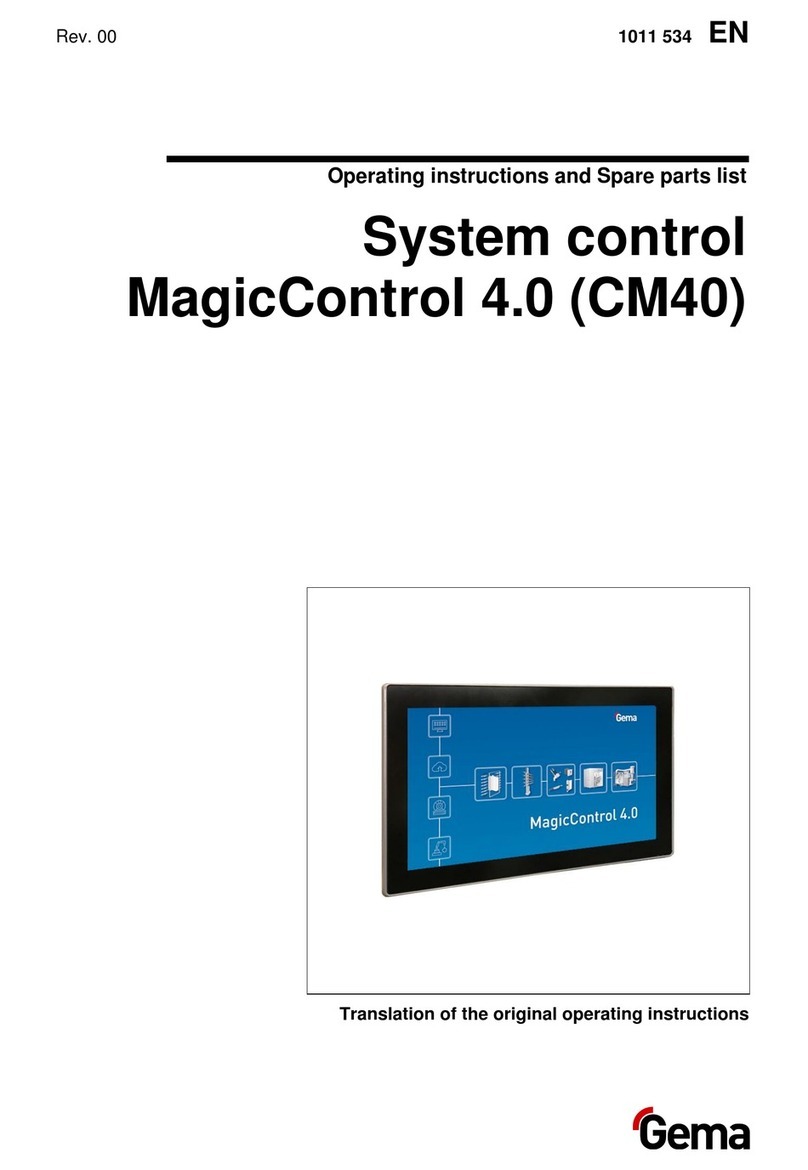

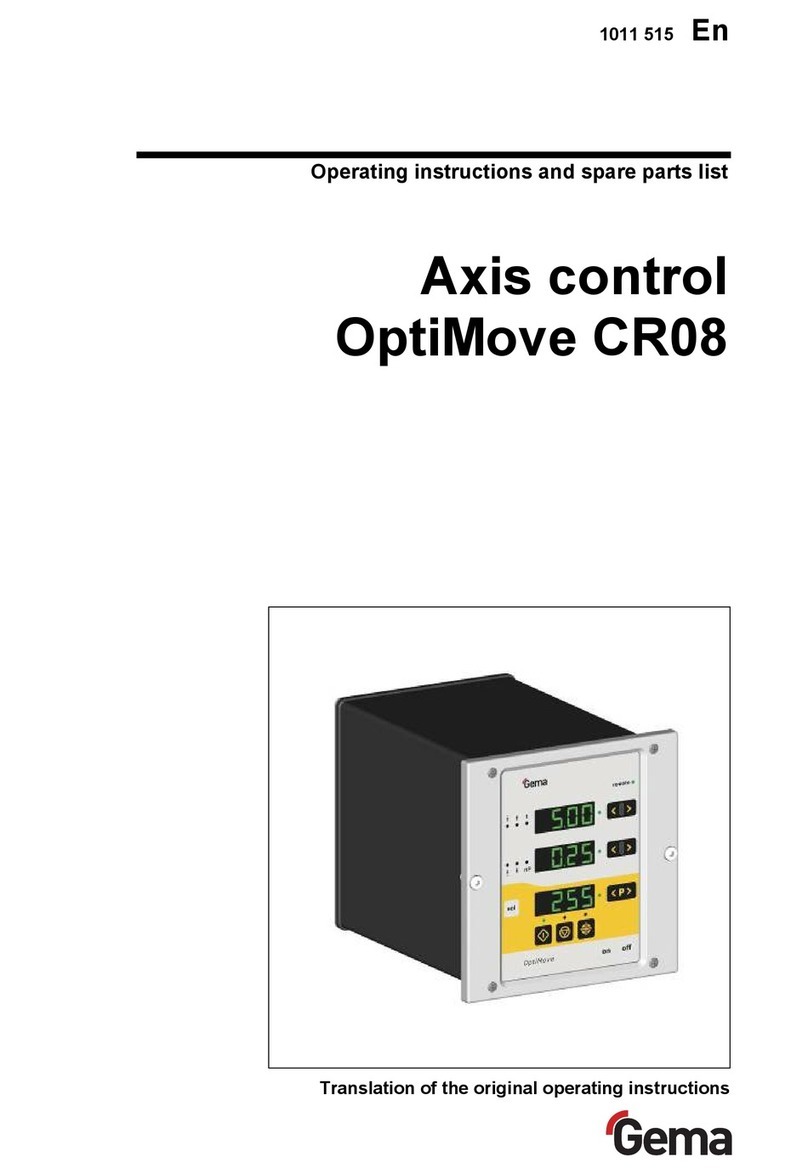

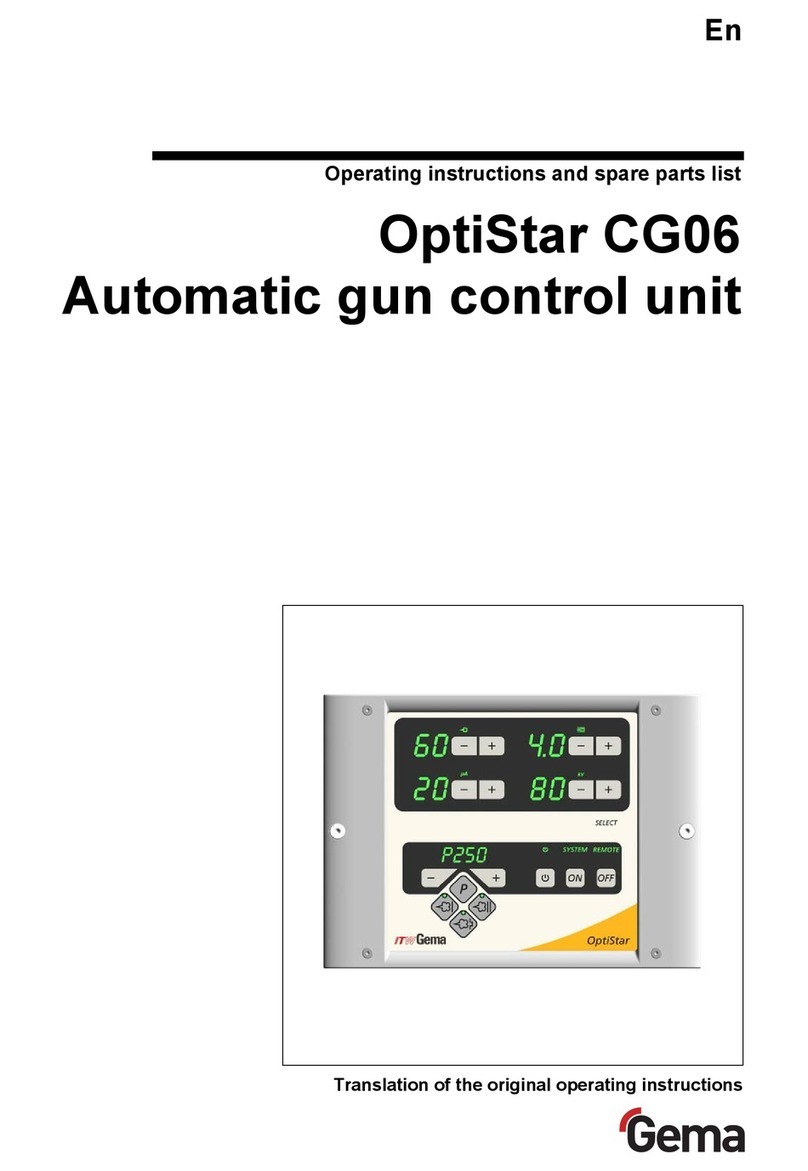

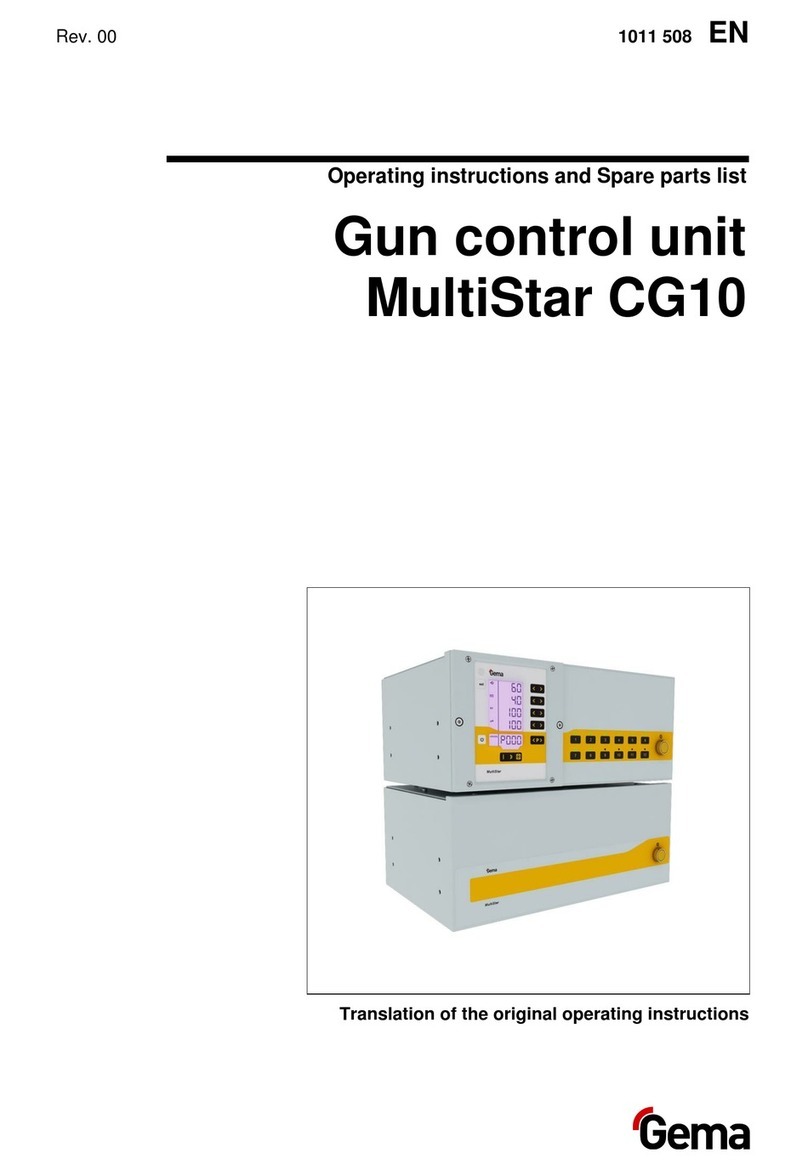

Touch panel / operating panel 27

Typical characteristics.......................................................................................... 27

Technical Data...................................................................................................... 28

System..................................................................................................... 28

Electrical data.......................................................................................... 28

Dimensions.............................................................................................. 28

Display..................................................................................................... 28

Connections............................................................................................. 29

Environmental conditions ........................................................................ 29

Rating plate ............................................................................................. 29

Design and function.............................................................................................. 30

Operating and display elements.............................................................. 30

Connections and interfaces..................................................................... 31

Symbols................................................................................................... 32

Meaning of the colors.............................................................................. 33

Operating modes.................................................................................................. 34

Coating .................................................................................................... 34

Cleaning/color change operating mode................................................... 34

Configuration........................................................................................... 35

Settings.................................................................................................... 35

User levels and access......................................................................................... 35

Functions available at user level............................................................. 36

CAN bus ............................................................................................................... 36

General.................................................................................................... 36

User administration............................................................................................... 36

Status display.......................................................................................... 36

Login........................................................................................................ 36

Log-out..................................................................................................... 40

Change user............................................................................................ 40

User profile .............................................................................................. 40

Diagnostic............................................................................................................. 49

Operating data......................................................................................... 50

Checking the software version ............................................................................. 51

Assembly / Connection 53

Set-up................................................................................................................... 53

Grounding of the powder management center..................................................... 53

Compressed air supply............................................................................ 54

Start-up 55

Preparation for start-up......................................................................................... 55

Basic conditions....................................................................................... 55

Basic information..................................................................................... 55

Inserting the SD card............................................................................................ 56

Inserting SD card..................................................................................... 56

Removing SD card .................................................................................. 56

Parameter description .......................................................................................... 56

Operation 59

Operation.............................................................................................................. 59

Starting the OptiCenter......................................................................................... 59