V 02/18

OptiStar CG08(-C) Table of contents •1

Table of contents

General safety regulations 3

Safety symbols (pictograms)...................................................................................3

Proper use...............................................................................................................3

Product-specific safety measures ........................................................................... 4

OptiStar CG08 Gun control unit.................................................................4

About this manual 5

General information ................................................................................................5

Software version .....................................................................................................5

Product description 7

Field of application ..................................................................................................7

Technical data.........................................................................................................8

OptiStar CG08 - versions...........................................................................8

Connectable guns ......................................................................................8

Electrical data ............................................................................................ 8

Pneumatic data ..........................................................................................9

Dimensions ................................................................................................9

Powder output (guide values) ....................................................................9

Air flow rates ............................................................................................10

Design and function ..............................................................................................11

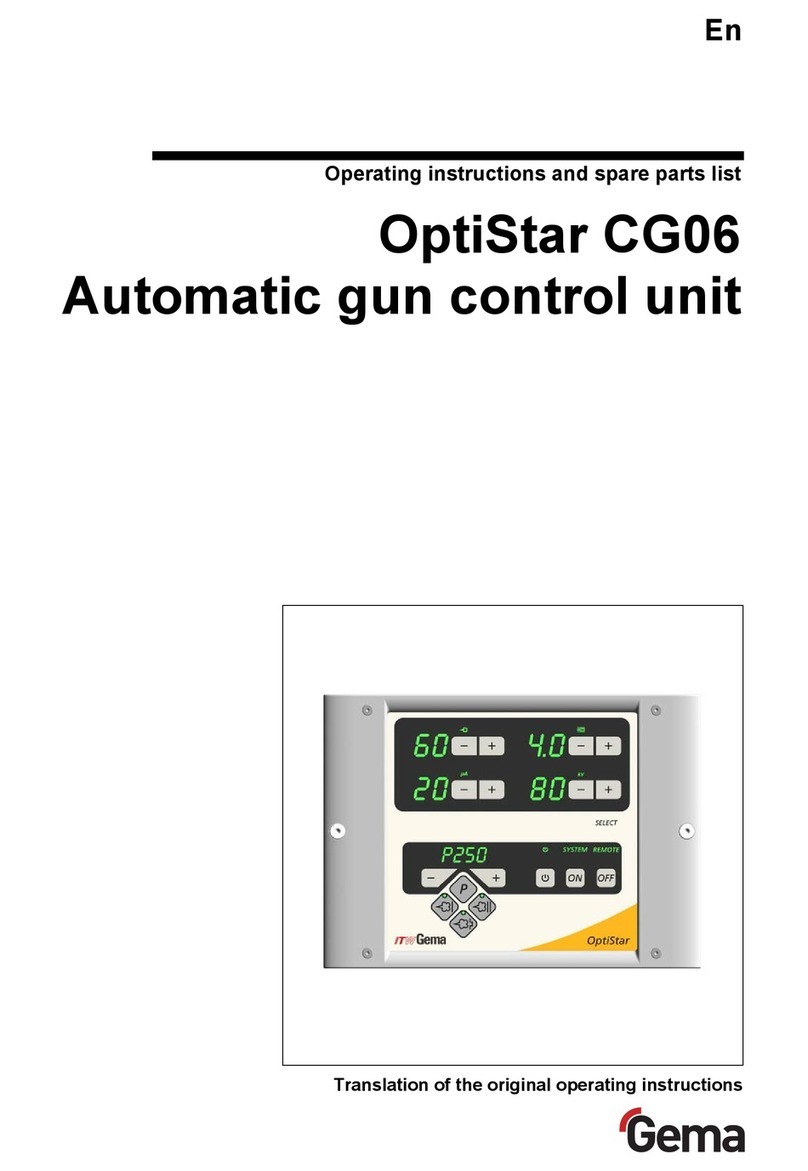

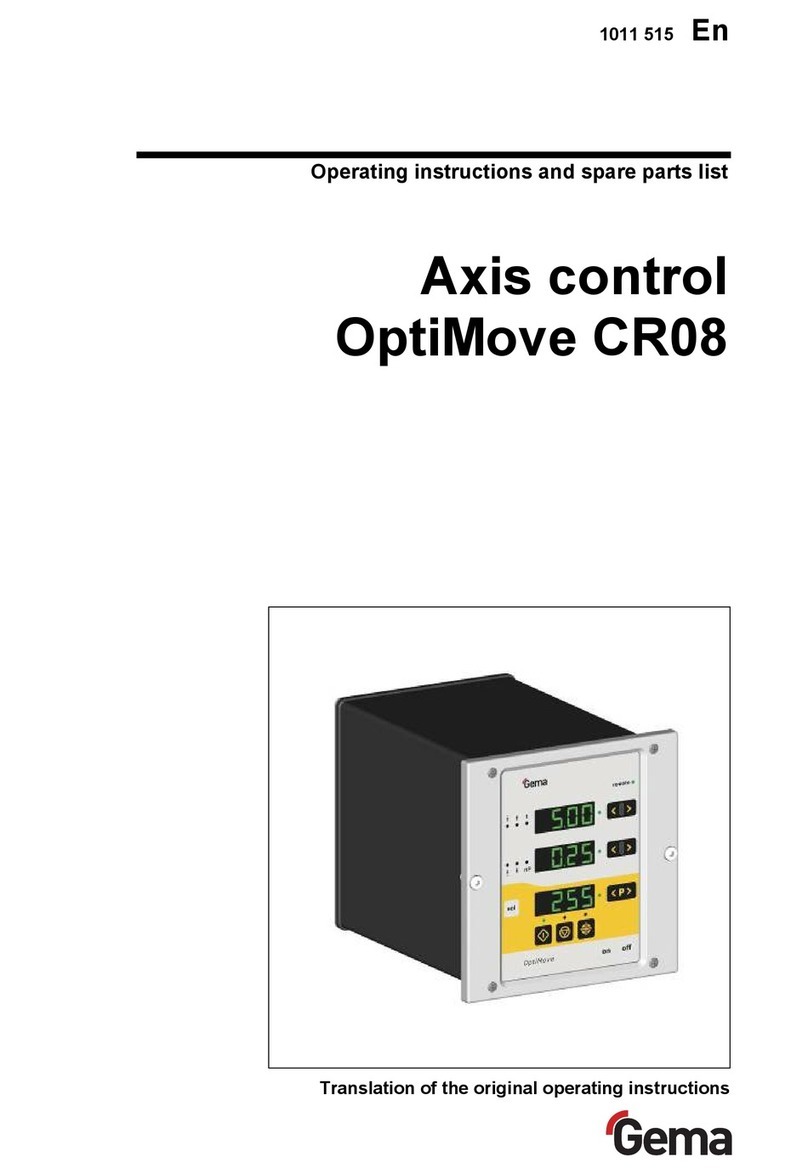

General view ............................................................................................11

Operating elements..................................................................................12

Input keys and switches...........................................................................14

Connections .............................................................................................15

Pin assignment ........................................................................................16

CG08-C pin assignment...........................................................................16

Scope of delivery ..................................................................................................16

Typical properties – Characteristics of the functions ............................................17

Operating modes .....................................................................................17

Rinsing mode ...........................................................................................18

Monitoring of wearing parts......................................................................19

Keyboard lock ..........................................................................................20

Background illumination...........................................................................20

Correction factor for the powder output ...................................................21

Commissioning 23

Preparation for start-up .........................................................................................23

Basic conditions .......................................................................................23

Mounting instructions ............................................................................................23

Connection instructions.........................................................................................24

Initial start-up 27

System parameters...............................................................................................27

Entering the system parameters..............................................................27

Operation ..............................................................................................................31