V 02/16

OptiMove CR08 Table of contents • 1

Table of contents

About this manual 3

General information ................................................................................................3

Keeping the Manual ................................................................................................3

Presentation of the contents ...................................................................................3

Figure references in the text ......................................................................3

Safety symbols (pictograms)...................................................................................3

Software version .....................................................................................................4

Safety 5

Basic security instructions.......................................................................................5

Product specific security regulations ......................................................................5

Product description 9

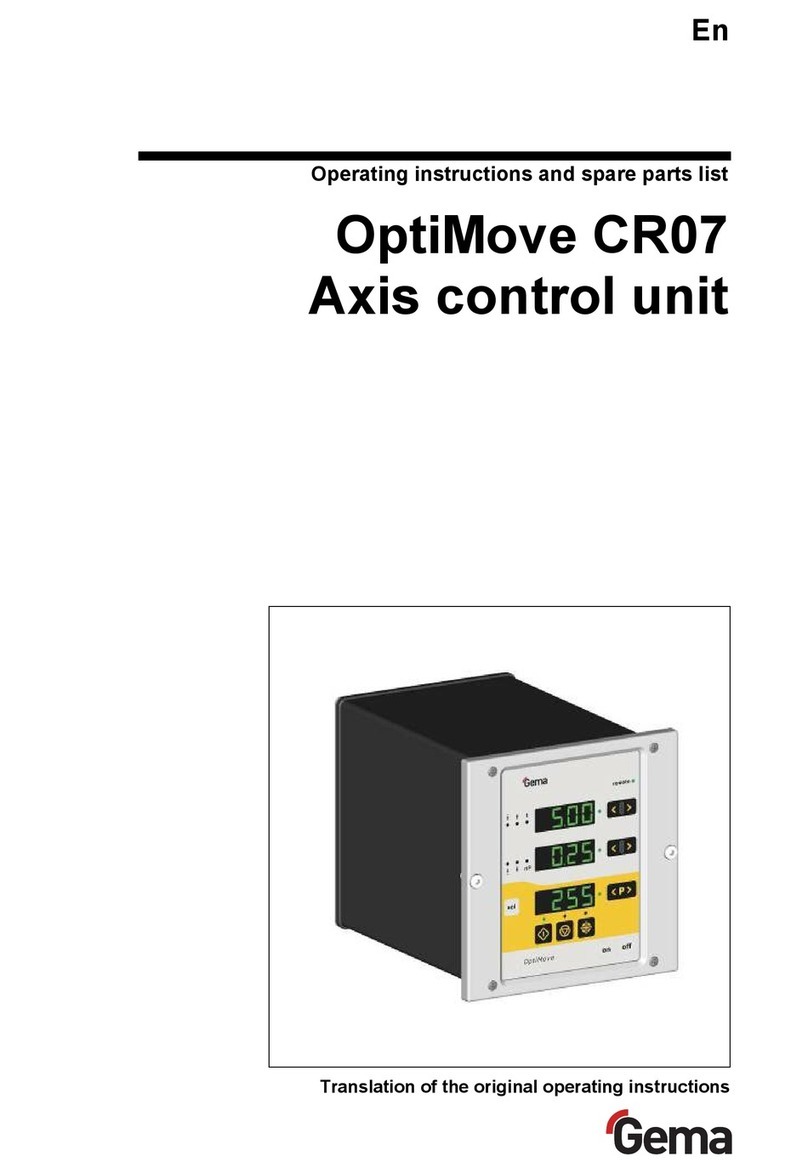

OptiMove CR08 axis control unit ............................................................................9

Operating panel .........................................................................................9

Intended use .........................................................................................................10

Reasonably foreseeable misuse...........................................................................10

Technical data.......................................................................................................10

Connectable axes ....................................................................................10

General data ............................................................................................10

Electrical data ..........................................................................................11

Dimensions ..............................................................................................11

Design and function 13

Structure................................................................................................................13

Function description..............................................................................................13

Configuration............................................................................................14

Operating and display elements, operating modes 15

Display and input buttons...................................................................................... 15

Operating modes ..................................................................................................18

"Manual" operating mode.........................................................................18

Keyboard lock ..........................................................................................18

Start-up 19

Connections – rear side ........................................................................................19

Initial start-up.........................................................................................................20

Measures before initial start-up................................................................20

Electrical wiring and screening concept...................................................20

Setting the system parameters .............................................................................20

System parameters – overview................................................................21

System parameter P1 – setting the upper stroke limit.............................22

Operation 23

Operating the axis control unit ..............................................................................23

Switch on/off the axis control unit .........................................................................23