3 / 66 1436 cPos

Contents

1 General safety information 4

1.1 General information 4

1.2 Explanation of symbols and signs 4

1.3 Safety notes 4

1.4 Correct use 5

1.5 Information on use in damp conditions 5

1.6 Mounting position 5

1.7 Tools required for installation and assembly 5

2 Manufacturer's information 5

2.1 Transport 5

2.2 Delivery and performance 5

2.3 Storage 5

2.4 Function 5

2.5 Fail safe function 5

3 Diagrammatic view of the inputs and outputs 6

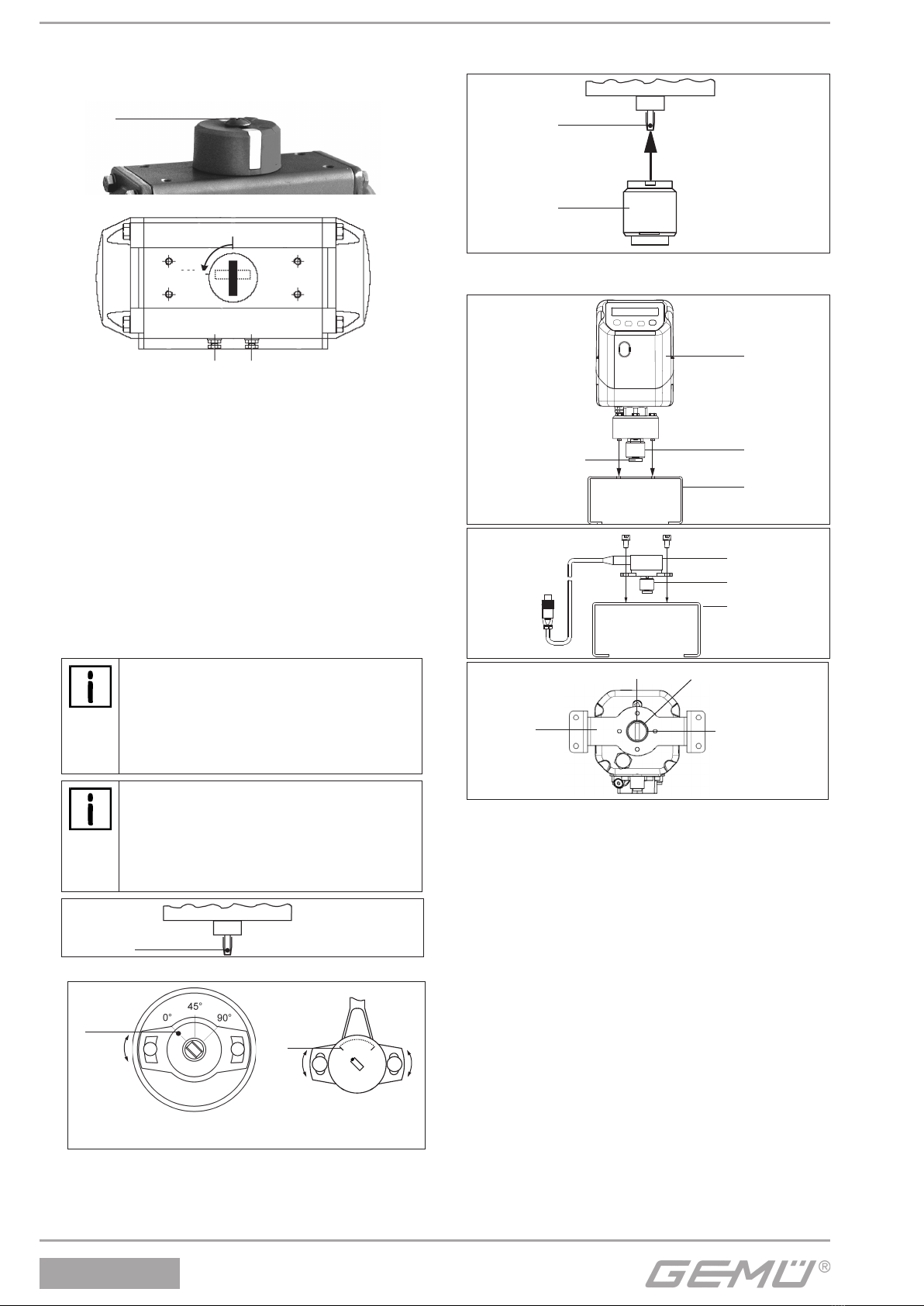

4 Mechanical mounting 7

4.1 Mounting to linear actuators 7

4.1.1 Preparation of the valve actuator 7

4.1.2 Assembling the travel sensor 7

4.1.3 Mounting the positioner 7

4.1.4 Mounting the external travel sensor

(only for version with remote mounting) 7

4.2 Mounting to quarter turn actuators 8

4.2.1 Preparation of the valve actuator 8

4.2.2 Assembling the travel sensor 8

4.2.3 Mounting the positioner 9

4.2.4 Mounting the external travel sensor

(only for version with remote mounting) 9

4.2.5 Checking the mounted assembly 9

4.3 Remote mounting to linear or quarter turn actuators 10

4.3.1 Preparation of the valve actuator 10

4.3.2 Assembling the travel sensor 10

4.3.3 Mounting the external travel sensor

(only for version with remote mounting) 10

4.3.4 Checking the mounted assembly 10

4.3.5 Mounting the mounting bracket 10

4.3.6 Connecting the travel sensor 10

5 Pneumatic connections 10

6 Electrical connections 10

6.1 Version with external actual value potentiometer

(code S01) 11

6.2 Supply voltage 11

6.3 Set value input

(only eective for AUTO operating mode) 11

6.4 Actual value input

(sensor signal when operating as a process controller) 11

6.5 Actual value output 11

6.6 Outputs 11

6.7 Digital inputs 11

6.7.1 Use of actual value and set value inputs as digital

inputs 12

6.8 Digital inputs (optional) 12

6.9 RS232 – Interface 12

7 Operation 13

7.1 Operating and display elements 13

7.2 Menu levels 13

7.2.1 Working level (Mode) 13

7.2.2 Conguration level (Setup) 13

8 Changing parameters 13

9 Commissioning 14

9.1 General information 14

9.2 Initial commissioning without factory setting

(when supplied without a valve) 14

9.2.1 Automatic initialisation 14

9.2.2 Manual initialisation 14

9.2.3 Menu structure automatic and manual initialisation 15

9.2.4 Error messages during initialisation 16

9.2.5 Initialisation parameters 17

9.3 Initial commissioning with factory setting

(positioner supplied mounted to the valve) 17

10 Operating modes 19

10.1 Operating mode selection 19

10.2 Automatic operation (A:) 19

10.3 Manual operation (M:) 19

10.4 Manual operation with exible

set value specication (F:) 19

10.5 Test mode (T:) 19

10.6 Pause mode (OFF) 19

11 Congurationmenu(Setup) 20

11.1 Changes in the conguration menu 20

11.2 Access authorisation in the conguration menu 20

11.3 Menu structure 1 Service 21

11.4 Menu structure 2 SetBasics 22

11.5 Menu structure 3 SetFunction 23

11.6 Menu structure 4 SetCalibration 24

11.7 Menu structure 5 Communication 25

12 Parameter table 26

13 Explanation of parameters 30

13.1 1 Service 30

13.1.1 Scanning the input and output signals 30

13.1.2 Activating or deactivating the user access 31

13.1.3 Reading out, deleting and deactivating error

messages 32

13.1.4 Display serial number, software version and ID and

enter TAG no. 32

13.2 2 SetBasics 33

13.2.1 Denition of actual value and set value inputs 33

13.2.2 Reset 33

13.2.3 Initialisation 33

13.2.4 Making the display settings 33

13.3 3 SetFunction 34

13.3.1 Setting the process controller parameters (optional) 34

13.3.2 Setting the positioner parameters 35

13.3.3 Setting the dead zone 35

13.3.4 Setting the optional digital input parameters 35

13.3.5 Setting output functions and switch points 36

13.3.6 Setting the error time and error action 37

13.3.7 Storing parameter sets 37

13.3.8 Dening the actual value output 37

13.4 4 SetCalibration 38

13.4.1 Determining the direction of actual value and set

value 38

13.4.2 Dening the characteristics of the control curve 38

13.4.3 Dening the direction of the travel sensor 39

13.4.4 Dening the actual value output signal 39

13.4.5 Determining switch points for error monitoring 39

13.4.6 Scaling the actual value and set value display 39

13.5 5 Communication 40

13.5.1 Setting the eldbus parameters 40

13.5.2 Setting the communication parameters 40

14 Error messages 41

15 Quick guide 42

15.1 Changing the set value signal and actual value

signal 42

15.2 Switching the process controller on or o (optional) 42

15.3 Changing the control parameters

(Proc P, Proc I, Proc D and Proc T) 43

16 General information regarding control

engineering 44

16.1 The control circuit 44

16.2 Control engineering terminology 44

16.3 Control parameters 44

16.4 Adaptation of the controller to the controlled system 45

16.5 Dierential equation for the GEMÜ 1436 cPos 45

16.6 Eects of the control parameters on the control

system 45

16.7 Control characteristics and transitory responses 46

17 Table for changes to the factory settings 47

17.1 Changed control parameters 47

17.2 Set values for the freely programmable

characteristic curve 49

18 Disposal 49

19 Returns 49

20 Information 49

21 Technical data 50

22 Order data 51

23 Fail safe function 61

24 Application examples 62

24.1 GEMÜ 1436 cPos as process controller with

4-wire transmitter (GEMÜ 3021) 62

24.2 GEMÜ 1436 cPos s process controller with

2-wire transmitter (GEMÜ 3020) 62

25 EU Declaration of Conformity 63

List of terms 64