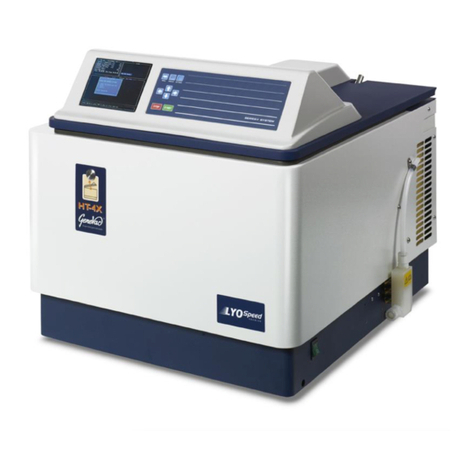

Genevac HT-8 & HT-12 Series II Evaporating Systems

04-4541 Issue 1-9 – June 2008 Page 3 of 64

Contents

1Introduction ........................................................................................................................................ 5

Amendment Control Form .................................................................................................................... 6

1.1 Safety symbols ..................................................................................................................................... 6

Genevac Evaporators and Combustible Solvents ............................................................................................. 6

2System description and options ....................................................................................................... 7

3Scope of delivery and installation ..................................................................................................... 8

3.1 Checking the delivery ........................................................................................................................... 8

3.2 Arranging commissioning ..................................................................................................................... 8

3.3 Training ................................................................................................................................................ 8

3.4 Positioning the evaporator .................................................................................................................... 8

3.5 Fitting the vacuum pump ...................................................................................................................... 9

4Safety ................................................................................................................................................ 10

4.1 Safe loading of rotor ........................................................................................................................... 10

4.2 Safe loading of rotor – General Document ......................................................................................... 11

Nomenclature ..................................................................................................................................... 11

Use of Correct Accessories ................................................................................................................ 11

Adherence to Mass Limit .................................................................................................................... 12

Safe loading of sample holders into swings ........................................................................................ 12

Incorrect – Sample Holder rotated ...................................................................................................... 12

Correct – Sample Holder well seated ................................................................................................. 12

Incorrect – Sample Holder on edge of swing ...................................................................................... 12

Series I vs Series II Swings: ............................................................................................................... 13

Balancing of swings and sample holders. ........................................................................................... 13

Good procedural practice ................................................................................................................... 14

4.3 Safe door operation ............................................................................................................................ 15

4.4 Limitations of use ............................................................................................................................... 15

5Getting started .................................................................................................................................. 15

5.1 How to switch on the pump ................................................................................................................ 16

5.2 How to switch on the evaporator ........................................................................................................ 16

5.3 Using the keypad ............................................................................................................................... 17

5.4 What the screens do .......................................................................................................................... 18

Sample Holder Type ........................................................................................................................... 19

Sample Volume .................................................................................................................................. 19

Solvent ............................................................................................................................................... 20

SampleGuard Control Temperature ................................................................................................... 22

SampleGuard Control Channel .......................................................................................................... 22

Coolheat Enable Pressure ................................................................................................................. 22

Chamber Temperature Control ........................................................................................................... 22

Rotor Speed ....................................................................................................................................... 23

Heat-Off Option .................................................................................................................................. 23

During a run ....................................................................................................................................... 24

5.5 How to enter control data ................................................................................................................... 27

5.6 How to use SampleGuard .................................................................................................................. 32

5.7 How to use the condenser .................................................................................................................. 34

5.8 How to start a run ............................................................................................................................... 36

6Getting the best from your system ................................................................................................. 39

6.1 Routine Checks .................................................................................................................................. 39

6.2 Problem prevention ............................................................................................................................ 40

6.3 Optimising a run ................................................................................................................................. 41

6.4 Pre-programmed Runs ....................................................................................................................... 42

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com