www.GenieCompany.com/commercial | 800.843.4084

Model GCL - T / J / H

Standard-Duty Specifications

PART 1 – GENERAL

1.01 WORK INCLUDED

A. Provide electric door operator(s) of size and capacity recommended for door(s)

as provided by door manufacturer with electric motor and factory pre-wired

motor controls, starter, reduction unit, disc brake (option for no brake on 1/2

HP), clutch, control devices, and accessories required for proper operation.

1.02 RELATED WORK

A. Opening preparation, miscellaneous or structural metal work, access, field

electrical wiring, wire conduit, fuses and disconnect switches are in the

Scope of Work of other divisions or trades.

1.03 QUALITY ASSURANCE

A. In accordance with accepted quality assurance guidelines for motor-operated

doors, both the door and electric operator shall be manufactured by a single-

source producer of door systems.

PART 2 - PRODUCT

2.01 GENERAL

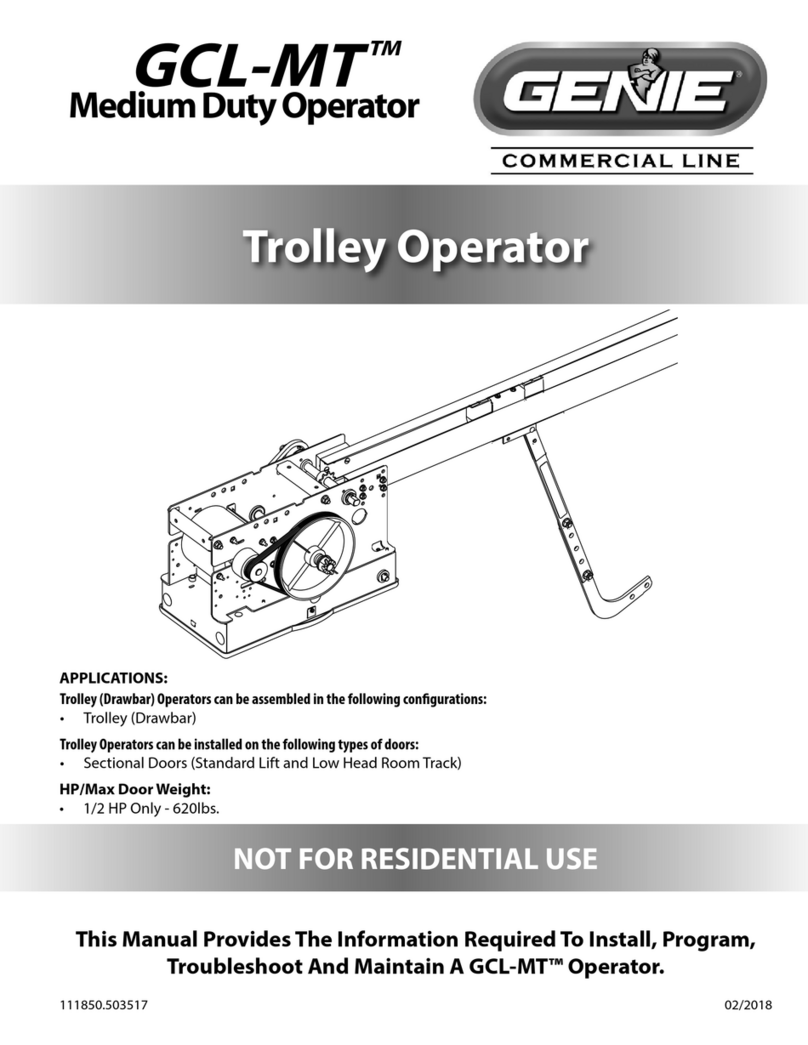

A. The electric door operator shall be the Model GCL Standard-Duty door control

system for a (standard lift) (lift-clearance), (full-vertical) sectional door and /

or (rolling steel door) and /or (rolling steel grille) as manufactured by The

Genie Company and suitable for the type and size of door specified.

B. The electric operator shall be (single phase) (three phase) with MultiVolt™ -

the ability to adjust to the correct voltage of (115/208/230 for single phase)

(208/230/460 for three phase) without removal or addition of any parts. (The

electric operator shall be 575VAC three phase).

C. All components to have corrosion resistant coatings.

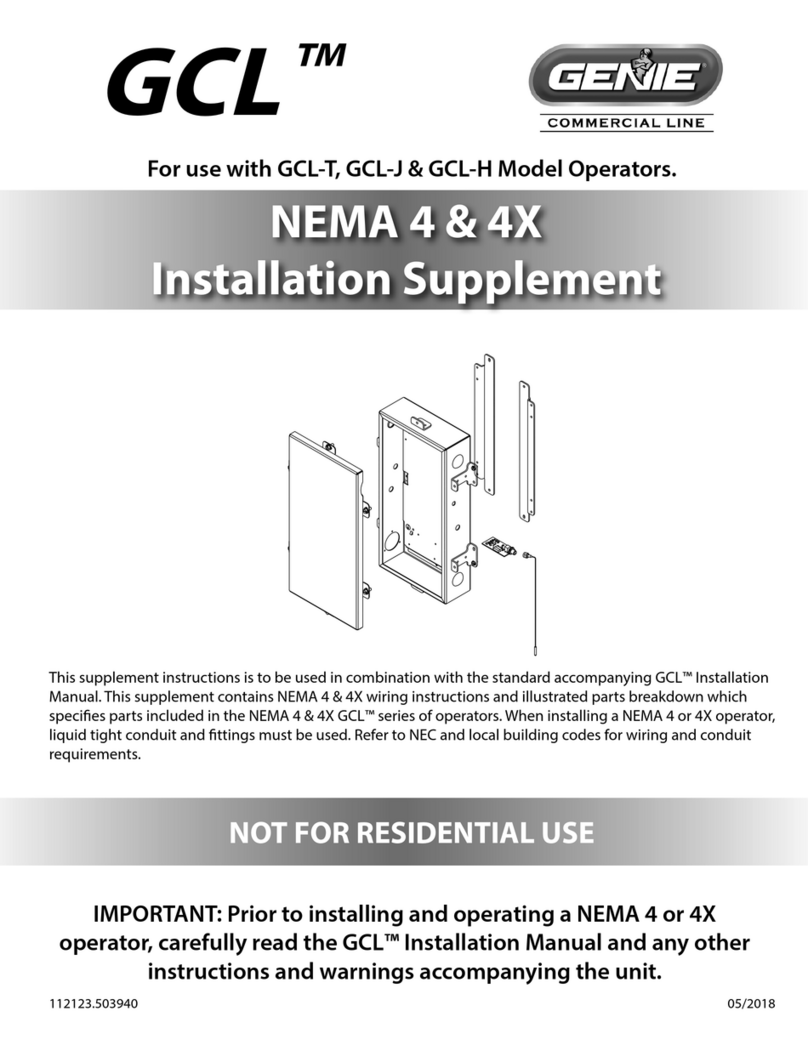

D. The operator shall be suited for NEMA ICS 6 Type 1 (NEMA ICS 6 Type 4)

(NEMA ICS 6 Type 4X) environment.

2.02 MOTOR

A. Motor shall be:

a. (1/2 horsepower single phase or three phase with automatic thermal

reset overload)

b. (3/4 horsepower or 1 horsepower single phase with manual reset

overload)

c. (3/4 horsepower or 1 horsepower three phase with automatic thermal

reset overload)

Motor frame shall comply with NEMA (48 for ½ HP single phase) (56 for

½ HP three phase, ¾ & 1 HP all phases), (open drip-proof construction)

(Totally Enclosed Non Ventilated – TENV construction) (Totally Enclosed Fan

Cooled – TEFC construction).

2.03 REDUCTION

A. Primary reduction is TensiBelt™, an auto-tensioning poly-V flex belt that does

not require adjustment. Secondary reduction is by chain and sprocket.

2.04 DUTY CYCLE

A. Duty cycle shall accommodate standard usage, up to 30 cycles per hour, not

to exceed 100 cycles per day.

2.05 BRAKE

A. Brake shall be a DC Disc type with selectable Progressive Braking for

smooth stopping.

2.06 CLUTCH

A. Clutch shall be adjustable friction disc type standard on all versions.

2.07 LIMIT SYSTEM

A. The EZ Limit™ system shall be magnetic type providing absolute positioning

with push to set capabilities. The Limit System shall remain synchronized

with the door during manual operation and supply power interruptions.

2.08 CONTROL SYSTEM

A. The control system shall be microprocessor-based with relay motor controls

on a single board. This system will incorporate a 16-character liquid crystal

display (LCD) to display the system status. This system shall be capable

of monitoring and reporting on a variety of operating conditions, including:

current operating status, current command status, motor movement status,

current error status (if applicable), hoist Interlock status (if applicable),

external Interlock status, and 24VDC status.

B. The control system shall feature a delay-on-reverse operating protocol.

C. The system shall include maximum run timers in both directions of travel that

limit motor run time in the event a clutch slips or some other problem occurs.

D. It shall include provisions for the connection of a 2-wire monitored photocell

system or a 2-wire monitored edge sensor, as well as non-monitored 2-wire

sensing edges, photocells or other entrapment protection devices.

E. Control action will be constant contact close until a monitored entrapment

device is installed, allowing for selection of momentary contact.

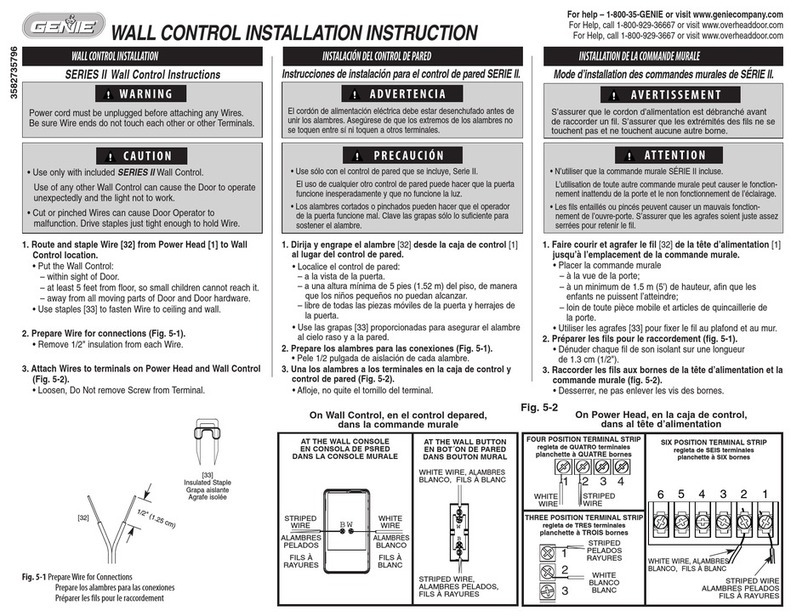

F. The system shall include provisions for connection of single and/or 3-button

control stations.

G. The system shall include provisions for connection of an external 3-wire

radio control and related control devices.

H. The control system shall include on board open, close and stop control keys

for local operation.

I. Trolley operators shall include an inherent, secondary reversal system.

J. The control system will include an IntelliCode® I radio receiver that is

315Mhz and capable of storing 50 single button and/or 50 open-close-stop

transmitters with the ability to add and/or delete transmitters individually,

identify and store activating transmitter ID(s).

2.09 MOUNTING

A. Mounting for sectional doors shall be side (center) by chain/sprocket on

(jackshaft) (hoist) models.

B. Mounting for sectional doors via drawbar coupling for (trolley)(side-mount

trolley) (dual trolley).

C. Mounting for rolling steel doors shall be (front of hood) (wall-mount)

and chain/sprocket coupling to door.

D. Mounting for hoist models shall be ordered from factory (left hand) (right

hand).

2.10 RELEASE

A. (Release shall be a pull and hold type mechanism with single cable operation

and an integrated interlock switch on hoist units.) (Release shall consist of a

manual disconnect door arm on trolley units).

2.11 HOIST

A. Chain hoist shall consist of chain pocket wheel, chain guard and smooth

hand chain on hoist units. Standard on hoist models (optional on trolley as

side mount kit).

2.12 SECONDARY REVERSAL

A Trolley version only shall include an integral electronic reversing system that

will stop and reverse a closing door upon detection of an obstruction and

designed to accept an optional external reversing device.

B. (Jackshaft)(Hoist) models shall be designed to accept an optional external

reversing device.

NOT FOR RESIDENTIAL USE.

2.13 OPTIONAL CONTROL ACCESSORIES

A. Control accessories: In (lieu of) (addition to) (interior push-button control

station) (exterior push-button control station) (interior key switches) (exterior

key switches) (radio control) (Genie monitored photo electric eyes)

(commercial photo electric eyes) (floor loops) (motion sensors).

B. Operator accessories shall be timer to close and will provide auxiliary control

inputs, auxiliary safety inputs, auxiliary timer hold input, and an automatic

door closing feature with a user selectable time delay. Safety inputs are to be

enabled or disabled using the on board keypad.

C. Operator accessories shall be Auxiliary Output Module and will provide

several auxiliary sets of dry contacts that are microprocessor controlled.

Provides contacts for (up) (down) (mid-stop) limit. Provides contacts to be

configured using the on board keypad to activate (lights)(horn)(strobes) while

door is running (up)(down)(both up and down).

PART 3 - EXECUTION

3.01 The Model GCL Standard Duty™ shall be installed in accordance with The

Genie Company instructions and standards. Installation will be by trained

and authorized Genie Company distributors or dealers.

©2012 The Genie Company. All Rights Reserved.

A copyright license to reproduce this specification is hereby granted to non-

manufacturing architects, engineers and specification writers.

Note to specifier:

This specification is a suggested guide. Available options are shown in parentheses.