4

Important notes

Usage for the intended purpose

The level electrode NRG 10-52 / NRG 16-52 in conjunction with level switch NRS 1-.. is designed for

signalling up to four different water levels and used for instance in steam boiler plants and (pressurized)

hot-water installations or in condensate and feedwater tanks, e. g. as water level limiter with MIN/MAX

alarm.

The level electrode is designed for use in conjunction with the following level switches: NRS 1-52,

NRS 1-53, NRS 1-54 and NRS 1-55 or NRS 1-1, NRS 1-2, NRS 1-3 and NRS 1-5.

Function

The electrode operation is based on the conductive measuring principle using the electrical conductiv-

ity of the water for signalling water level. The length of the individual electrode rods determines the

switchpoints for the respective water levels.

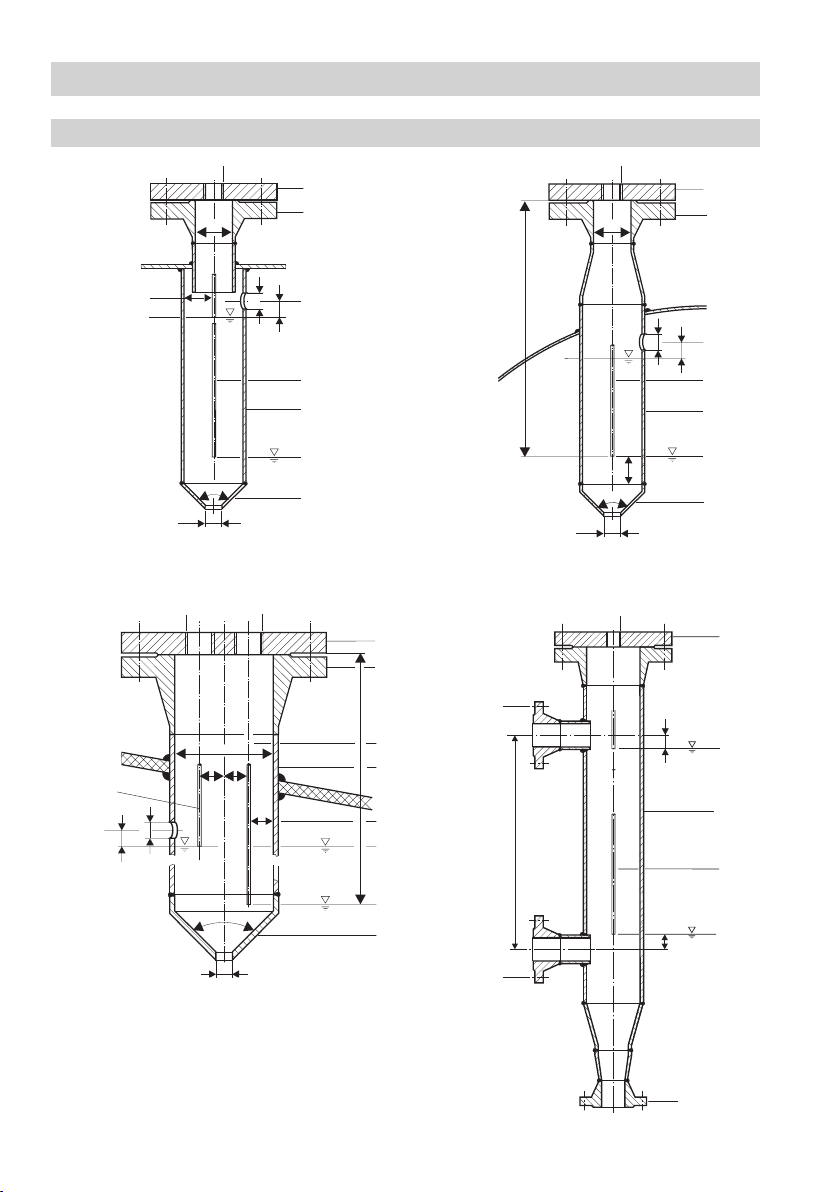

The level electrode is installed inside steam boilers, vessels or in an external level pot. If the electrode

is installed inside the boiler or vessel, a protection tube provided on side ensures correct functioning.

(see section Examples of installation on page 10).

The level electrode can be installed together with one GESTRA level electrode for water level limiting or

for high-level alarm in a single protection tube or external level pot.

Safety note

Danger

When loosening the electrode steam or hot water might escape!

This presents the risk of severe scalding all over the body!

It is therefore essential not to dismantle the electrode unless the boiler pressure is

verified to be 0 bar.

The electrode becomes hot during operation.

Risk of severe burns to hands and arms.

Before carrying out installation and maintenance work make sure that the equipment is

cold.

Attention

The name plate specifies the technical features of the equipment. Do not commission or

operate any item of equipment that does not bear its specific name plate.

The equipment must only be installed, wired and commissioned by qualified and competent staff.

Retrofitting and maintenance work must only be performed by qualified staff who - through adequate

training - have achieved a recognised level of competence.