2716

12345678

17 18 19 20 21 22 23 24

9

25

10

26

11 12

28

13

29

14

30

15

Test Test

Description

The NRS 1-50 level switch is used in conjunction with

NRG 1...-50 level electrodes as a water level limiter for steam

boilers and hot water installations.

Water level limiters switch off the heating when the water drops

below the set low water level (LW).

The NRS 1-50 level switch can be combined in a circuit with

the level electrodes stipulated by the standards below:

Standard Type of level electrode

UL 60730-2-15,

CAN/CSA E60730-2-15

NRG 16-50

NRG 17-50

NRG 19-50

Function

The NRS 1-50 level switch is designed for different boiler water

conductivities and for the connection of two level electrodes.

If the water falls below the minimum level, the level elec-

trodes are exposed and an alarm is triggered in the level

switch. This switchpoint is determined by the length of the

electrode extension.

When the off delay has elapsed, the two output contacts of

the level switch open the safety circuit for heating. The heating

cut-off is interlocked in the external safety circuit and this

interlock can only be deactivated again when the level electrode

is immersed once more. The NRS 1-50 level switch must be

used in combination with an external manual reset when used

as a protective device per ASME CSD-1.

In addition, two signal contacts for external signaling devices

close without a delay.

An alarm is also triggered if faults occur in a level electrode

and/or the electrical connection.

The manufacturer recommends connection pipes of ≥ 1.57in

(40mm) for steam and ≥ 3.94in (100mm) for water. If smaller

connection pipes or fittings are used, these shall not be smaller

than 1-inch NPS. The level pot must have a suitable flushing

device at its lowest point. This device flushes the connection

pipes to the boiler and enables the function of the water level

limiter to be tested.

No shut-off valves of any type shall be placed in the piping

between the boiler and the low water cutoff.

An automatic self-test monitors the safety functions in the level

switch and the level electrode. In the event of a fault, the safety

circuit opens without a delay and switches the heating off.

Alarm and fault indications are displayed by LEDs and an alarm

can be simulated by pressing a button.

Water Level Limiter

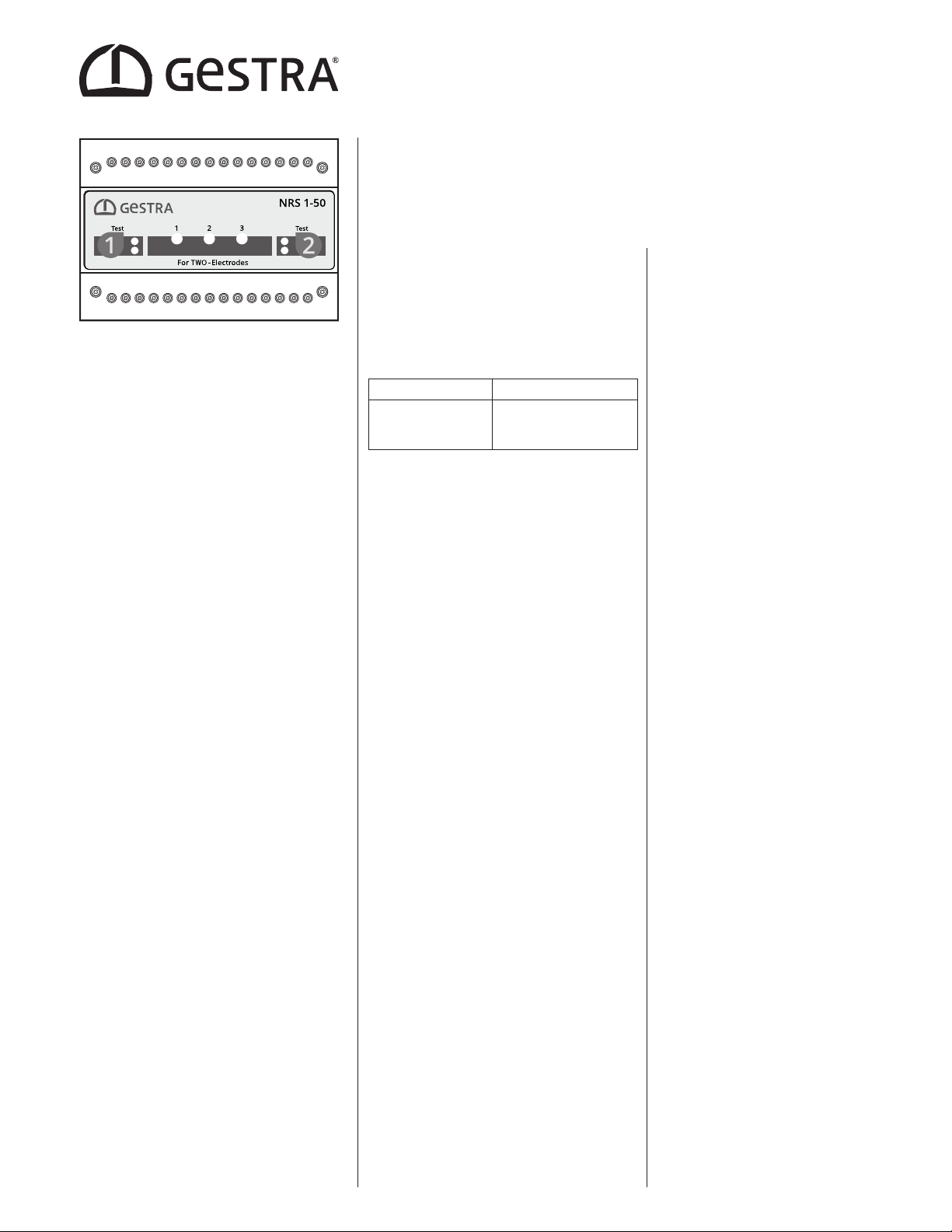

Level Switch

NRS 1-50

For TWO electrodes

Data sheet 850711-00

Issue date: 09/21

USA

Technical data

Supply voltage

24 VDC +/–20%, 0.3 A; SELV / PELV / CLASS2

100 – 240 VAC +10/-15%, 47 – 63 Hz, 0.2 A (optional)

Fuse

External 0.5A; UL category JDYX, e.g., RND 170-00012

Power consumption

7 W

Response sensitivity [Water conductivity at 77°F (25°C)]:

> 5 ... < 5000 ppm (> 10 ... < 10000 µS/cm)

Connecting the level electrode

Please use the following to connect the level electrode(s):

nA shielded, multi-core TC-ER control cable with a minimum

wire size of AWG18, e.g., OELFLEX CONTROL TM CY 5G1.

Max. length 328ft (100m).

Safety circuit

2 volt-free NO contacts, 6 A 250 V AC / 30 V DC cos ϕ= 1.

Off delay 3 seconds. Inductive loads must have interference

suppression (RC combination) in accordance with the manu-

facturer's specification.

Signal output

2 volt-free outputs for external signaling without a de-

lay, 24 V DC, max. 100 mA (semiconductor output).

Connection of control cables 2 x AWG20 (0.5 mm2).

Indicators and controls

2 buttons for testing and diagnosis, 4 red/green LEDs for indi-

cating operating state and alarm. 3 red LEDs for fault diagnosis,

2 2-pole code switches for setting the number of electrodes.

Terminal box

Terminal box material: base of black polycarbonate, front of

gray polycarbonate. Terminal strips can be removed separately

Terminal box attachment: Mounting clip on support rail

TH 35, EN 60715.

Electrical safety

Pollution degree 2, overvoltage category II according

to UL 60730-1.

Protection

Terminal box: IP 40 according to EN 60529

Terminal strip: IP 20 according to EN 60529

As a UL open type, the equipment must be installed in a

control cabinet.

Weight

Approx. 1.1 lb (0.5 kg)

Ambient temperature

at power-on 32° ... 131°F (0° … 55°C),

in operation 14° … 131°F (-10° … 55°C)

Transport temperature

-4°F ... +176°F (-20°C ... +80°C) (<100hours),

defrosting time of de-energized equipment before it can be

put into operation: 24 hours.

Storage temperature

-4°F ... 158°F (-20°C ... +70°C),

defrosting time of de-energized equipment before it can be

put into operation: 24 hours.

Relative humidity

Max. 95%, non-condensing

Site altitude

Max. 6560 ft (2000 m)