2

Contents

Usage for the intended purpose ..............................................................................................................4

Function .................................................................................................................................................4

Safety note .............................................................................................................................................5

Important notes

Page

Directives and standards

VdTÜV Bulletin “Wasserstand 100” (= Water Level 100)..........................................................................6

LV (Low Voltage) Directive and EMC (Electromagnetic Compatibility) .......................................................6

ATEX (Atmosphère Explosible).................................................................................................................6

Note on the Declaration of Conformity / Declaration by the Manufacturer .........................................6

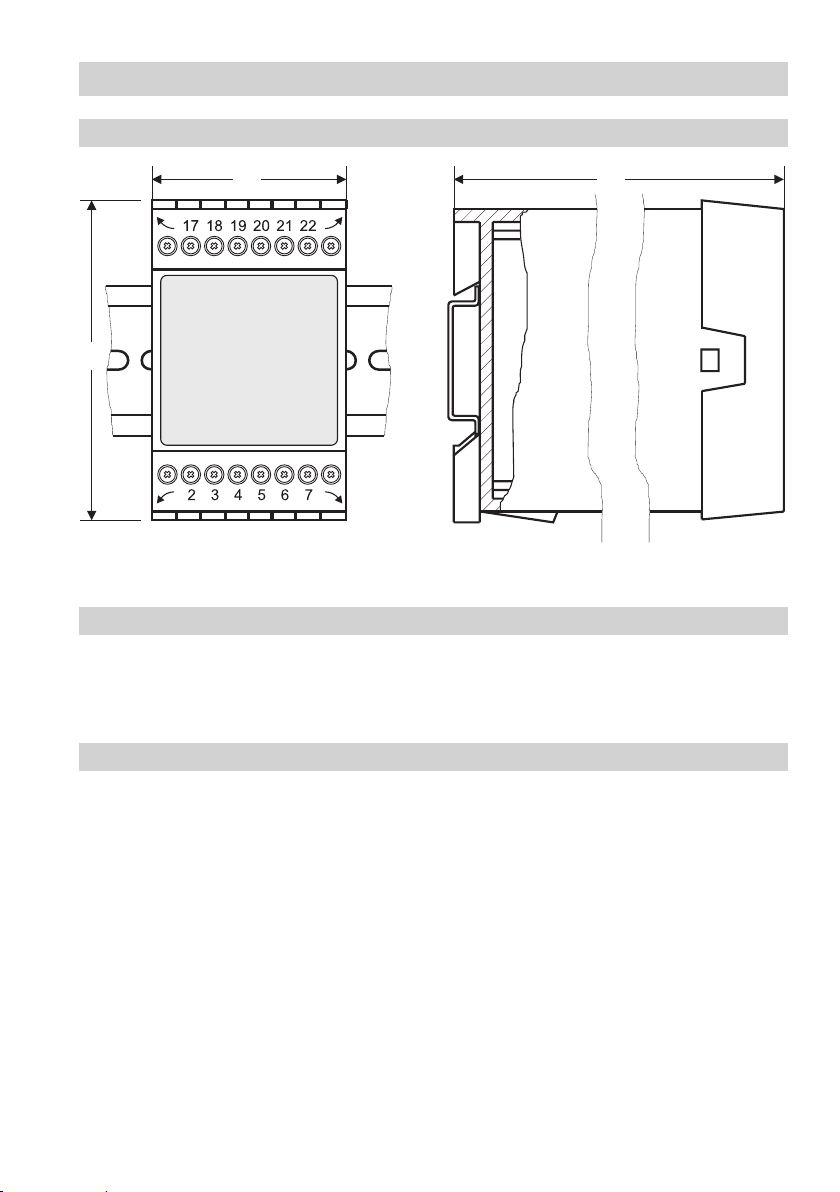

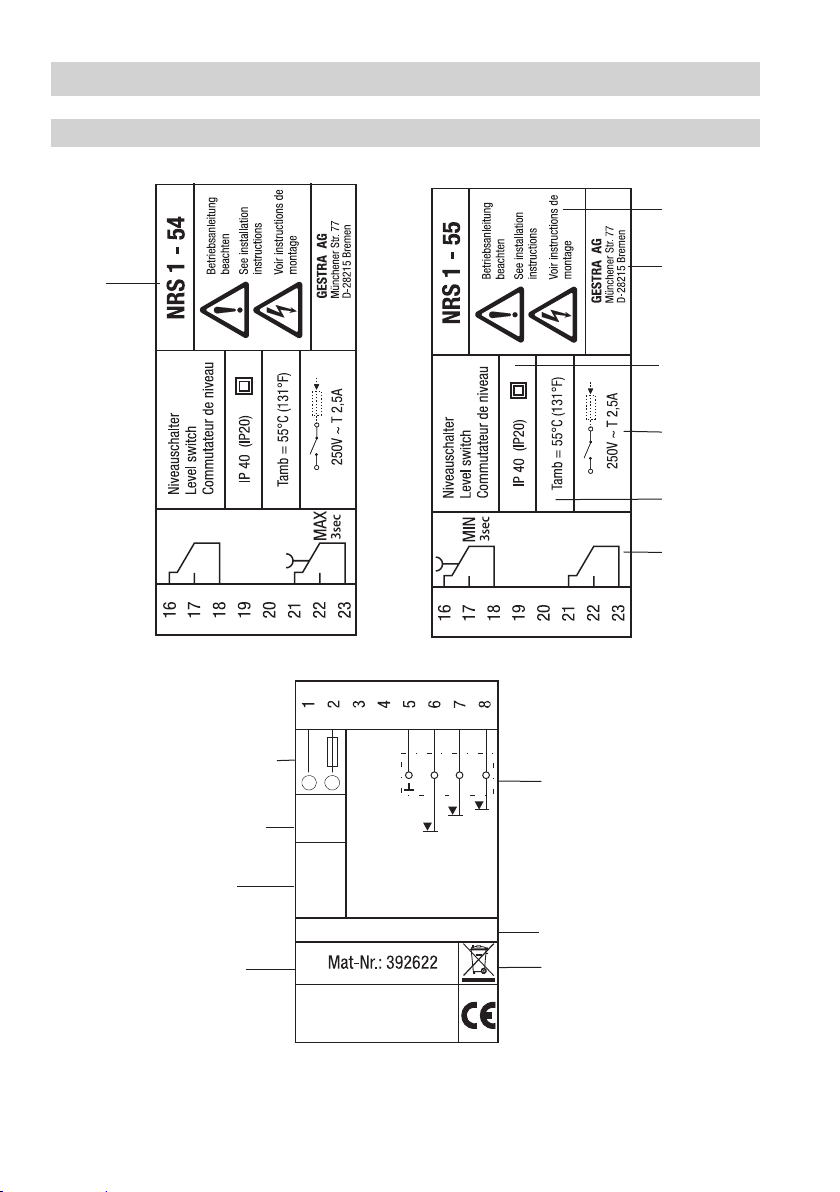

Dimensions NRS 1-54, NRS 1-55............................................................................................................9

Key.........................................................................................................................................................9

Installation in control cabinet ..................................................................................................................9

Name plate / marking ...........................................................................................................................10

In control cabinet: Mounting level switch

Wiring diagram for level switch NRS 1-54, NRS 1-55............................................................................11

Key.......................................................................................................................................................11

Connecting supply voltage ....................................................................................................................12

Connecting output contacts .................................................................................................................12

Connecting level electrode....................................................................................................................12

Tools.....................................................................................................................................................12

In control cabinet: Wiring level switch

Level switch NRS 1-54: Connecting several level electrodes (fill control)...............................................13

Key.......................................................................................................................................................13

Level switch NRS 1-55: Connecting several level electrodes (fill control)...............................................14

Key.......................................................................................................................................................14

Connecting level electrode....................................................................................................................15

In the plant: Wiring level electrode

NRS 1-54, NRS 1-55.........................................................................................................................7 – 8

Scope of supply......................................................................................................................................8

Technical data