2

Getinge9900-series Serviceinstructions

0103

Contents

Safety rules ________________________________________________ 4

General safety rules _______________________________________ 4

Service in washing chamber ________________________________ 4

Power cut-off device ______________________________________ 4

Caution symbols _________________________________________ 4

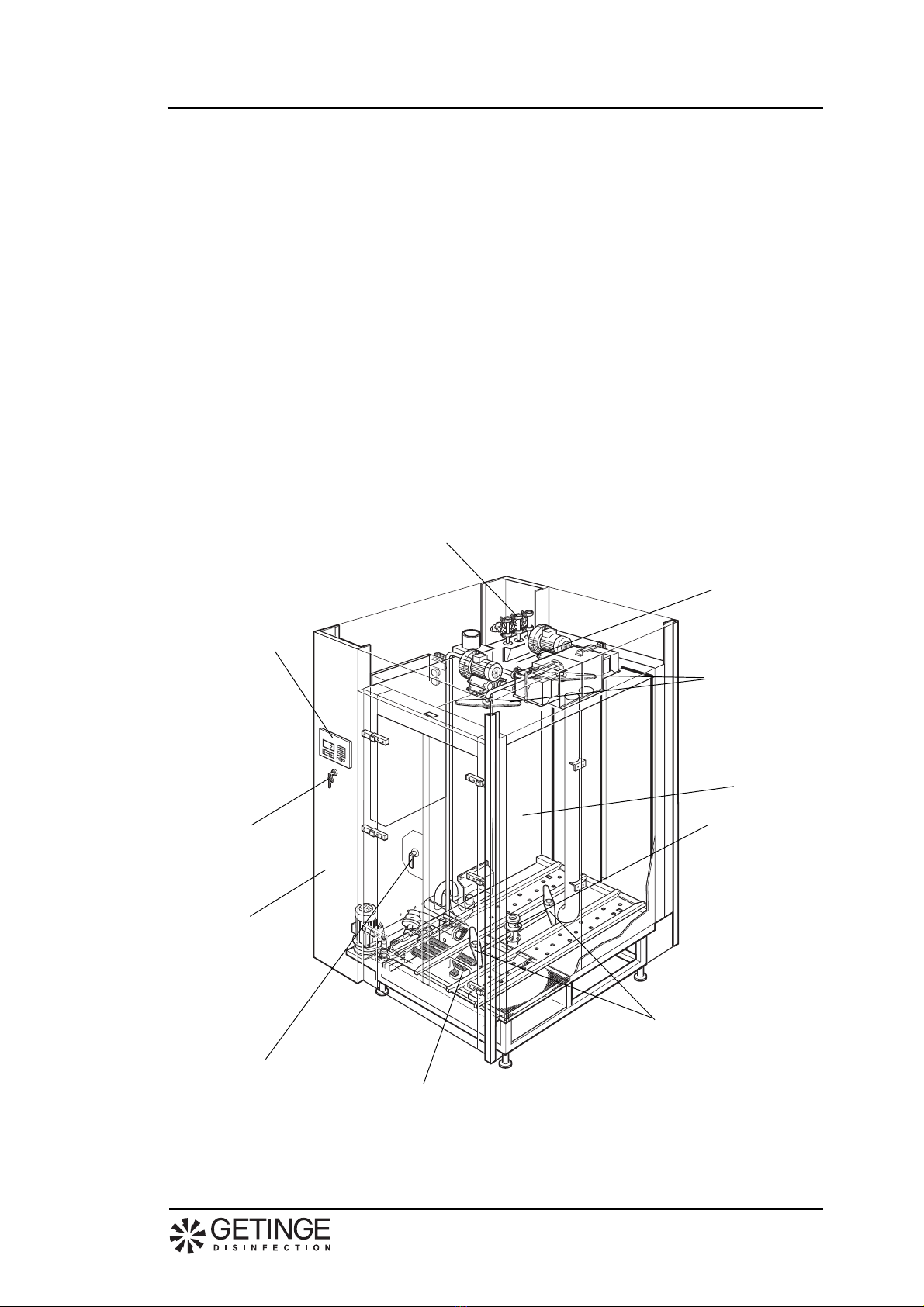

Description ________________________________________________ 5

rcuit diagram (steam heating)________________________________ 6

Safe and simple __________________________________________ 7

Simple service and installation ______________________________ 7

Door function ___________________________________________ 7

Dispenser system ________________________________________ 8

Programming device ______________________________________ 9

Aborting a process start ________________________________ 9

Aborting a process that is running _______________________ 10

Stepping quickly in a program ___________________________ 10

Resetting the machine RAM (Read Only Memory) ___________ 10

Calibrating the temperature while a process is running ________ 11

Technicaldata _____________________________________________ 12

Maintenance ______________________________________________ 14

Periodic maintenance _____________________________________ 14

Functional inspection ____________________________________ 15

Operating instructions, cable, switches ____________________ 15

Filters and valves _____________________________________ 15

Controls ____________________________________________ 15

Inserts for goods _____________________________________ 15

Door _______________________________________________ 16

Dosing the agents ____________________________________ 16

Flushing system ______________________________________ 16

Temperature check ____________________________________ 16

Dryer unit ___________________________________________ 16

Printer ______________________________________________ 16

Programming _____________________________________________ 17

Push-button functions ___________________________________ 17

Moving in the menu tree __________________________________ 19

Menu tree _____________________________________________ 20

Example and definition of program when programming ___________ 21

Creating a new program ___________________________________ 22

Phases and parameters ________________________________ 22

New program with existing program as basis (copying) _______ 24

Altering an existing program _______________________________ 26

Altering parameters and characters _______________________ 27

Adding a phase ______________________________________ 27

Deleting a phase _____________________________________ 27

Deleting a program ______________________________________ 28

Selecting a program with the program select keys _______________ 29

Program printout ________________________________________ 29

Choice of printer ________________________________________ 30

Choice of supply frequency _______________________________ 30

Choice of language ______________________________________ 31

Test __________________________________________________ 32