<Doc_INS><Doc_502404200><Rel_A><Lang_GB>

Page 4 of 24

SAFETY REGULATIONS

This machine has been designed with a number of built-in safety devices. To avoid in-

jury, it is highly important not to bypass or disable these safety devices.

If the equipment is used in a manner not specied by the manufacturer this can impair

the safety equipment on the machine.

Operators and maintenance personnel must undergo safety training for the machine.

All personnel who handle chemicals for washing and disinfection must understand the

washing process, possible health hazards and ways of detecting leaks of toxic chemicals.

Operators and maintenance personnel must undergo regular training in the operation and

maintenance of the equipment. There must be a documented list of personnel who have been

trained on the machine. Trained personal must be tested to verify the training programme.

Important

Take care when handling the chemical agents used in the machine.

Read the instructions on the pack or contact the manufacturer before using the ma-

chine for instructions about:

- what to do if the substance comes into contact with the eyes or skin or if

vapors are inhaled.

- storage of packs and sorting of empty packs for disposal.

The machine must be connected in accordance with the instructions given in the instal-

lation manual.

The machine may only be used by adults.

Installation and servicing may only be done by personnel trained for this machine.

Never bypass door safety switches.

Leaks in the system caused by worn seals in the door, for example, must be re-

paired immediately.

Before doing any repair or servicing work, the personnel concerned must study the

relevant handbooks and service manuals.

Before any welding is done, all cables connected to the control system via connec-

tors and sockets must be disconnected.

Before doing any servicing or maintenance work on the machine, isolate it from the

electric power supply and drain all tanks.

Do not wash down or hose down the machine with water.

Take care when using corrosive substances.

Observe safety measures for steam and hot water.

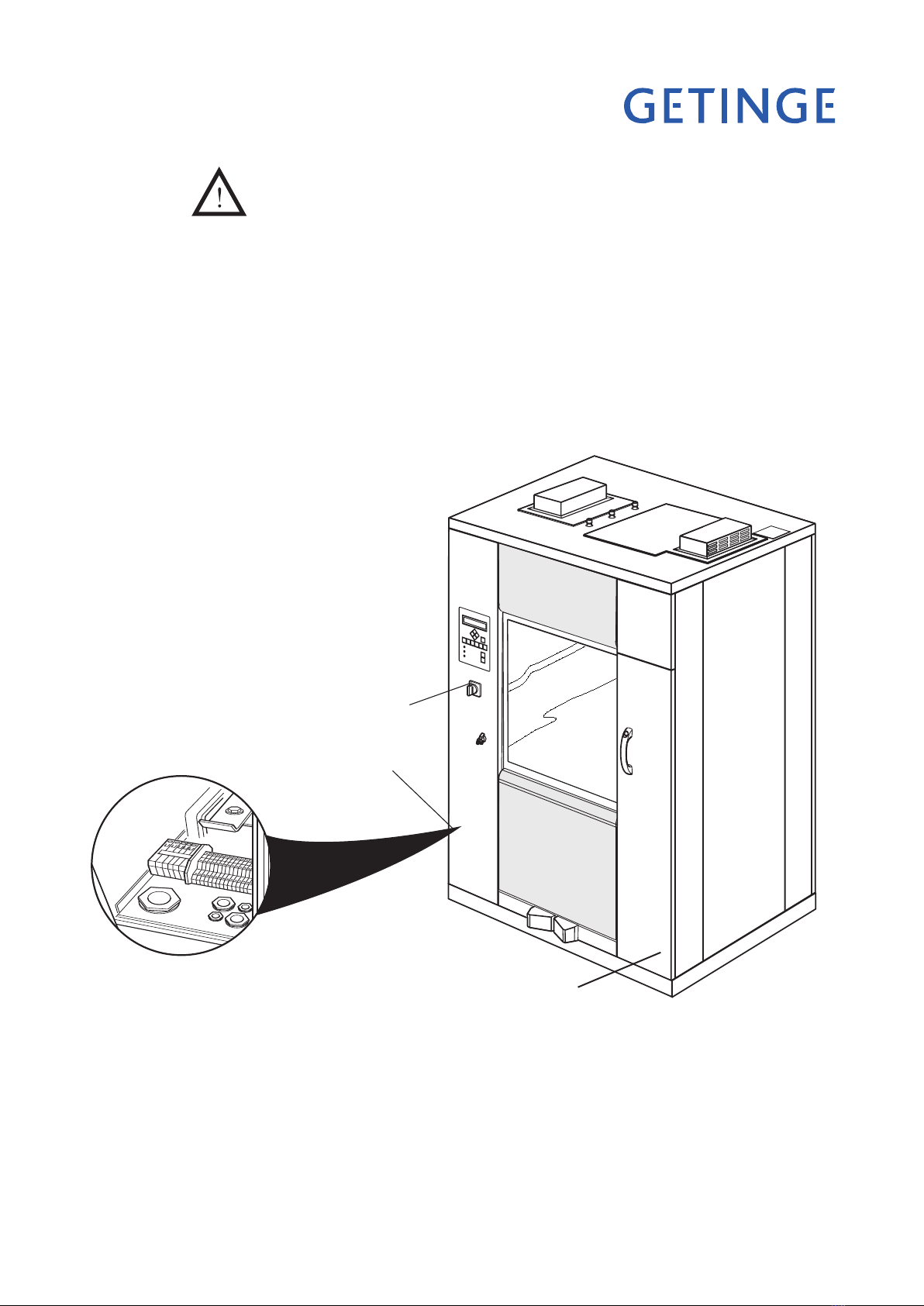

The machine must not be operated with cladding plates, roof and plinths removed.

Doing this puts at risk the safety and functioning of the machine.

The electrical cabinet may only be opened by authorized and trained personnel.

Spare parts may only be obtained from Getinge EDC.

The machine must be assembled and installed:

by qualied personnel.

in accordance with current local regulations and rules.

Warning!

To avoid the risk of back injury, this equipment should be assembled and

installed by two people.

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•