Page 3 av 64

<Doc_TEC><Doc_503712400><Rel_B><Lang_EN>

Contents

PREFACE_______________________________________________4

SAFETY REGULATIONS _________________________________5

General safety regulations ___________________________________ 5

In an emergency ___________________________________________ 5

Product liability ____________________________________________ 5

Isolator switch _____________________________________________ 5

INTRODUCTION ________________________________________6

Intended use of the machine_________________________________ 6

Attention symbols __________________________________________ 6

RCD ______________________________________________________ 6

Description _____________________________________________7

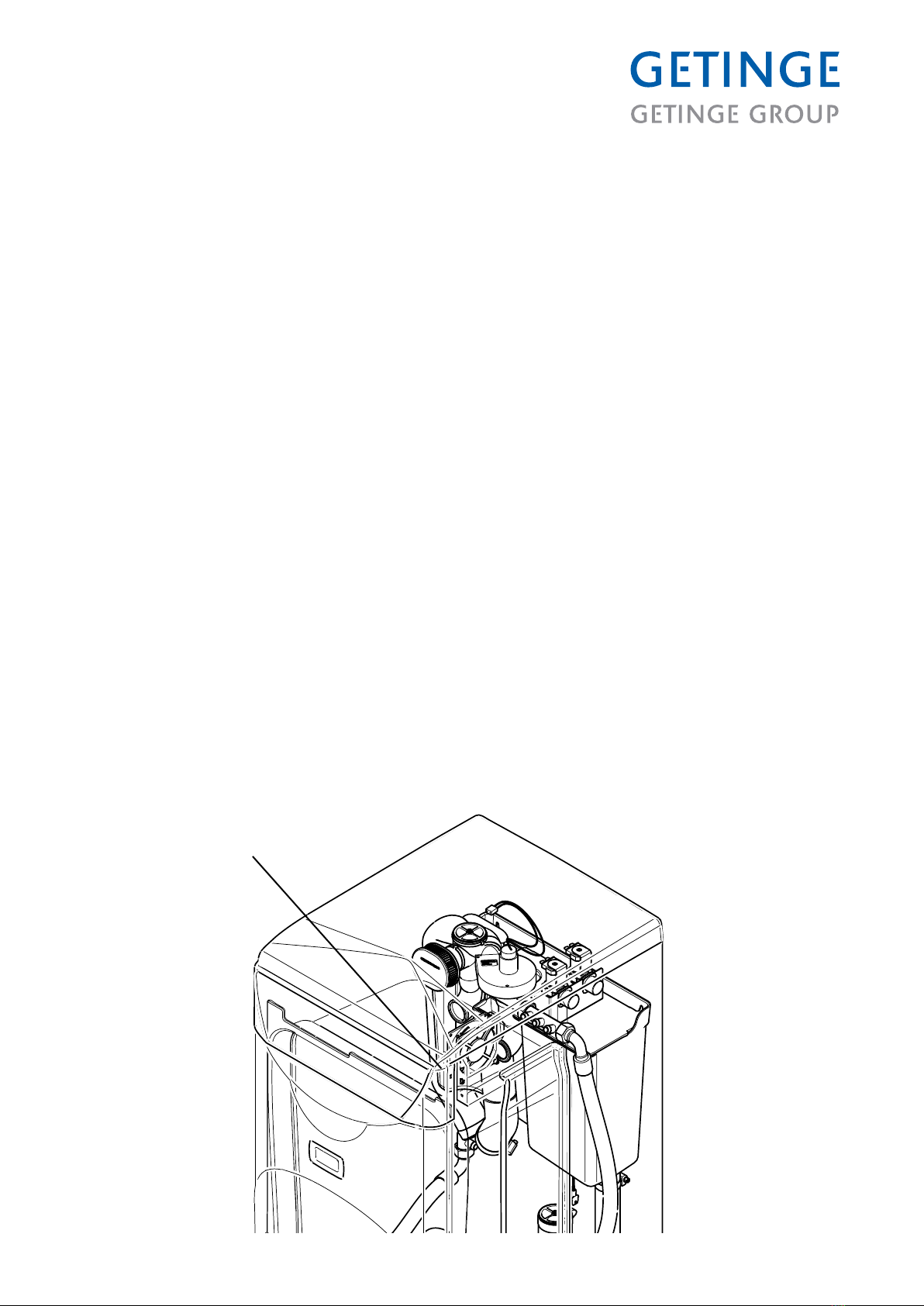

General ___________________________________________________ 7

Function __________________________________________________ 7

P&I diagram _______________________________________________ 8

Cooling ___________________________________________________ 9

Inspection hole ____________________________________________ 9

Service program ________________________________________11

Function __________________________________________________ 11

Table of line numbers and line information _____________________ 13

The service program________________________________________ 19

Machine-independent variables, lines 00-09 ___________________ 22

Interval disinfection, line 31 __________________________________ 28

Inspection request, line 32___________________________________ 29

Dosage, line 33 ____________________________________________ 30

Empty container alarm, line 34 _______________________________ 30

Disinfection, lines 35 - 49____________________________________ 30

Tank and water, lines 50 - 55_________________________________ 32

Fault statistics, lines 60 - 63 _________________________________ 34

Program statistics, lines 70 - 74 ______________________________ 35

Function test, lines 80 - 83 __________________________________ 36

Fault indications ________________________________________42

Fault message _____________________________________________ 42

Acknowledging a fault message______________________________ 43

Resetting the machine ______________________________________ 43

Table of faults and possible actions___________________________ 44

PREVENTIVE MAINTENANCE ____________________________45

Periodic maintenance_______________________________________ 45

Function check ____________________________________________ 47

Draining the machine _______________________________________ 60

Opening the door in the event of a power failure________________ 61

Component list ____________________________________________ 62