Grease Separator for Mobile Rinsing Equipment

Under Table Model

Installation, operating and maintenance instructions

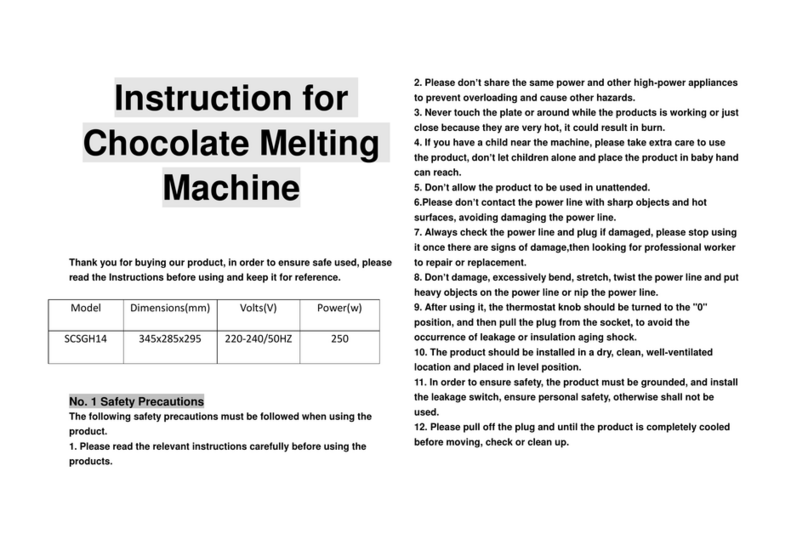

The grease separator for mobile rinsing equipment is designed for use under the following conditions:

- Connection of a commercially available dishwasher with a maximum water requirement of 5 litres per washing

cycle and a minimum washing time of 1 minute.

- In addition to a washing machine a maximum of one device can be connected for pre-rinsing of dishes and

short-term operation.

Installation

Set up in a freely accessible location to facilitate basic weekly cleaning. The unit should be installed on a rm

support and horizontally aligned.

- The grease separator intake (DN 50) at a higher level should be connected to the waste water feeder line using

a commercially available double socket. Ensure that the connection is watertight.

- The grease separator discharge (DN 50) at a lower level should be connected to the waste water line to the

channel using a commercially available plug-in socket, ensuring the connection is watertight (please note: do

not establish a permanent connection on the drainage system). Ensure there is an adequate gradient of 1 to

min. 2 cm/m.

Operating and maintenance instructions

Following connection of the supply and discharge lines at both ends, check the system for damage, tightness

and accessibility for inspection.

Initial use

The sludge and grease separator chamber should be lled with water prior to initial use until the water level in

the separator no longer rises or the water poured in begins to ow out. The cover should then be closed. Note as

a precaution that an odour trap should be tted to the grease separator feeder to avoid unpleasant smells from

the dishwasher or sink. This is provided on site as a standard feature in the majority of cases in accordance with

applicable regulations.

Operation

The unit can be commissioned after lling with fresh water. Only waste water containing vegetable or animal

fats or oils should be fed to the grease separator Mixing of grease from grease separators and other organic

fats (e.g. from fryers) should be avoided in all cases.

The grease which accumulates should be removed daily, collected in an airtight container and disposed of cor-

rectly. Flawless function is ensured through timely removal of grease.

The grease separator should be drained completely and cleaned after operation, or at least once a week and

when the location of use is changed. This is realised after grease removal. Unpleasant odours may emerge

when the system is opened.

The volume of water required for complete draining (water, grease, sludge) is approx. 60 litres. The unit should

be lled with fresh water prior to recommissioning. The system is now ready for operation again.

Grease Separator for Mobile Rinsing Equipment

Under Table Model

Installation, operating and maintenance instructions

The grease separator for mobile rinsing equipment is designed for use under the following conditions:

- Connection of a commercially available dishwasher with a maximum water requirement of 5 litres per washing

cycle and a minimum washing time of 1 minute.

- In addition to a washing machine a maximum of one device can be connected for pre-rinsing of dishes and

short-term operation.

Installation

Set up in a freely accessible location to facilitate basic weekly cleaning. The unit should be installed on a rm

support and horizontally aligned.

- The grease separator intake (DN 50) at a higher level should be connected to the waste water feeder line using

a commercially available double socket. Ensure that the connection is watertight.

- The grease separator discharge (DN 50) at a lower level should be connected to the waste water line to the

channel using a commercially available plug-in socket, ensuring the connection is watertight (please note: do

not establish a permanent connection on the drainage system). Ensure there is an adequate gradient of 1 to

min. 2 cm/m.

Operating and maintenance instructions

Following connection of the supply and discharge lines at both ends, check the system for damage, tightness

and accessibility for inspection.

Initial use

The sludge and grease separator chamber should be lled with water prior to initial use until the water level in

the separator no longer rises or the water poured in begins to ow out. The cover should then be closed. Note as

a precaution that an odour trap should be tted to the grease separator feeder to avoid unpleasant smells from

the dishwasher or sink. This is provided on site as a standard feature in the majority of cases in accordance with

applicable regulations.

Operation

The unit can be commissioned after lling with fresh water. Only waste water containing vegetable or animal

fats or oils should be fed to the grease separator Mixing of grease from grease separators and other organic

fats (e.g. from fryers) should be avoided in all cases.

The grease which accumulates should be removed daily, collected in an airtight container and disposed of cor-

rectly. Flawless function is ensured through timely removal of grease.

The grease separator should be drained completely and cleaned after operation, or at least once a week and

when the location of use is changed. This is realised after grease removal. Unpleasant odours may emerge

when the system is opened.

The volume of water required for complete draining (water, grease, sludge) is approx. 60 litres. The unit should

be lled with fresh water prior to recommissioning. The system is now ready for operation again.