1

0850EN May 2020

User and maintenance manUal

HigH or low temperature HiuswitH tHermostatic

control ge556Y320-321-322-323

ge556-4 series

1. General information

GE556Y320, 321, 322 and 323 HIUs enable metering thermal energy consumptions when heating and the production of Domestic

Hot Water (DHW) in modern autonomous systems with heat centralized production (eg. teleheating).

HIUs are controlled thermostatically by means of a 3-way priority valve.

Thermostatic control provides for the lowest return temperature when producing hot water.

1.1 Warnings

• Installation must be carried out by qualied personnel authorized by the building administration body. Comply with the regulations

in terms of use (installation, tting, etc...), operation, re-gauging and replacement of metering units. Also refer to assembly instructions

included with every metering unit.

• Risk of scalds and electric shocks. Only qualied personnel authorized by the building administration body should access the HIU.

Misuse may cause serious injuries to people and damage the system.

• An excessive temperature of the Domestic Hot Water may cause scalds to people; too cold water may lead to undesired bacterial

growth within the hot water system.

• Some HIU parts may overheat, do not touch them.

• Before connecting the HIU to the power line, make sure it has been properly lled with water. Starting the HIU without water inside

may damage the circulator and the HIU.

• When starting up the HIU, make sure no one uses the system water till the water temperature has been adjusted in order to prevent

scalds.

• To prevent polluting agents from entering the system, rst open the primary circuit valves and then the return valves when starting

up the HIU. Open the valves slowly to prevent pressure peaks.

• Do not cut o the electric power from the control panel. This may damage the circulator, the valve actuators, etc...

• The cleaning frequency of the sanitary water exchanger strongly depends on the hardness of the supply Domestic Cold Water.

• With water hardness values higher than 15°f we recommend using anti-scaling devices to be selected based on water characteristics.

• To enhance the resistance to limestone crusting, we recommend adjusting the sanitary water temperature at a value very close to

the value of actual use.

• When installing the HIU to control a low temperature zone, include a low-temperature safety thermostat on the controlled zone.

• Clean the sanitary water exchanger at the end of the rst year; then, based on the limestone crusting status, this period can be

extended to two years.

• The HIU can be used in closed boiler rooms for operation with non-aggressive uids (water, glycol-based water in compliance with

VDI 2035/ÖNORM 5195).

• The electrical installation must be done by qualied personnel, respecting the current legislation and Standards.

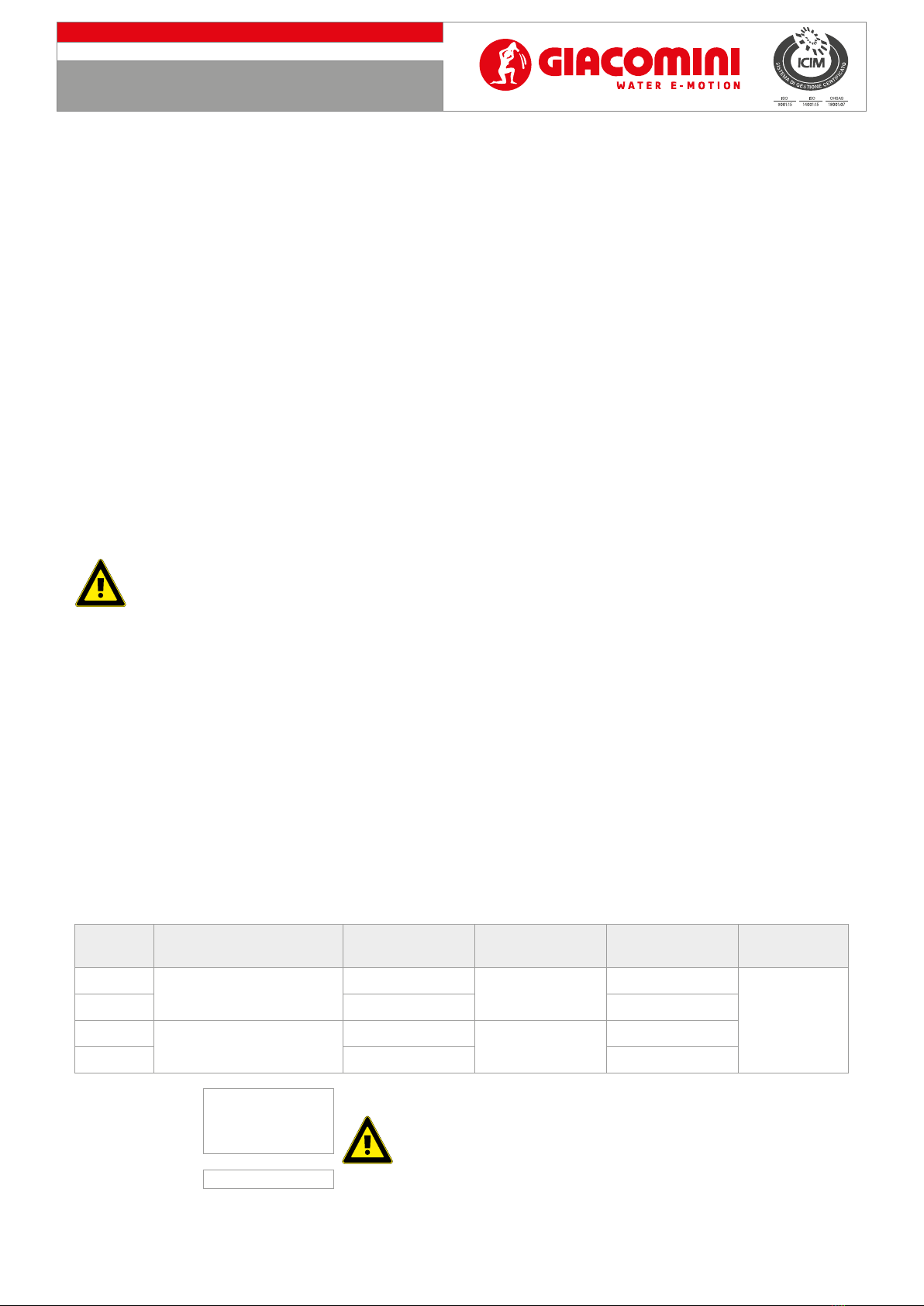

1.2 Versions and product codes

Product code Type Number of

exchanger plates Heating side power DHW exchanger

nominal power

Template with

valves

GE556Y320 High temperature heating and

DHW production

30 plates 21 kW 56 kW

GE551Y075

GE556Y321 40 plates 67 kW

GE556Y322 Low temperature heating and

DHW production

30 plates 10 kW 56 kW

GE556Y323 40 plates 67 kW

Warning.

• Every HIU includes:

- a label with the HIU model identication data;

- a label proving its compliance with electric and hydraulic tests;

• Every HIU is identied by a serial number both inside and on the packaging.