6

1022EN March 2020

Metering systeMs

Heat interface unit witH Heat excHanger for cooling

ge556Y174

ge556-1 series

047U58428

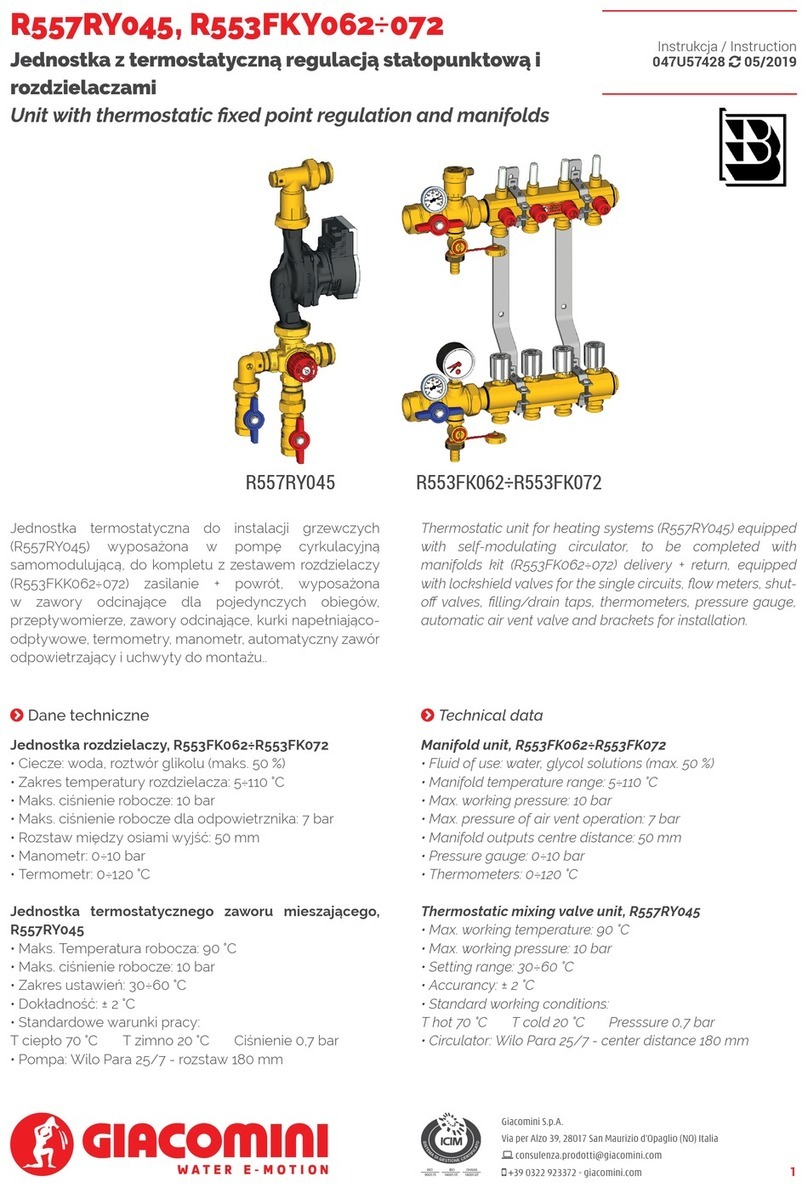

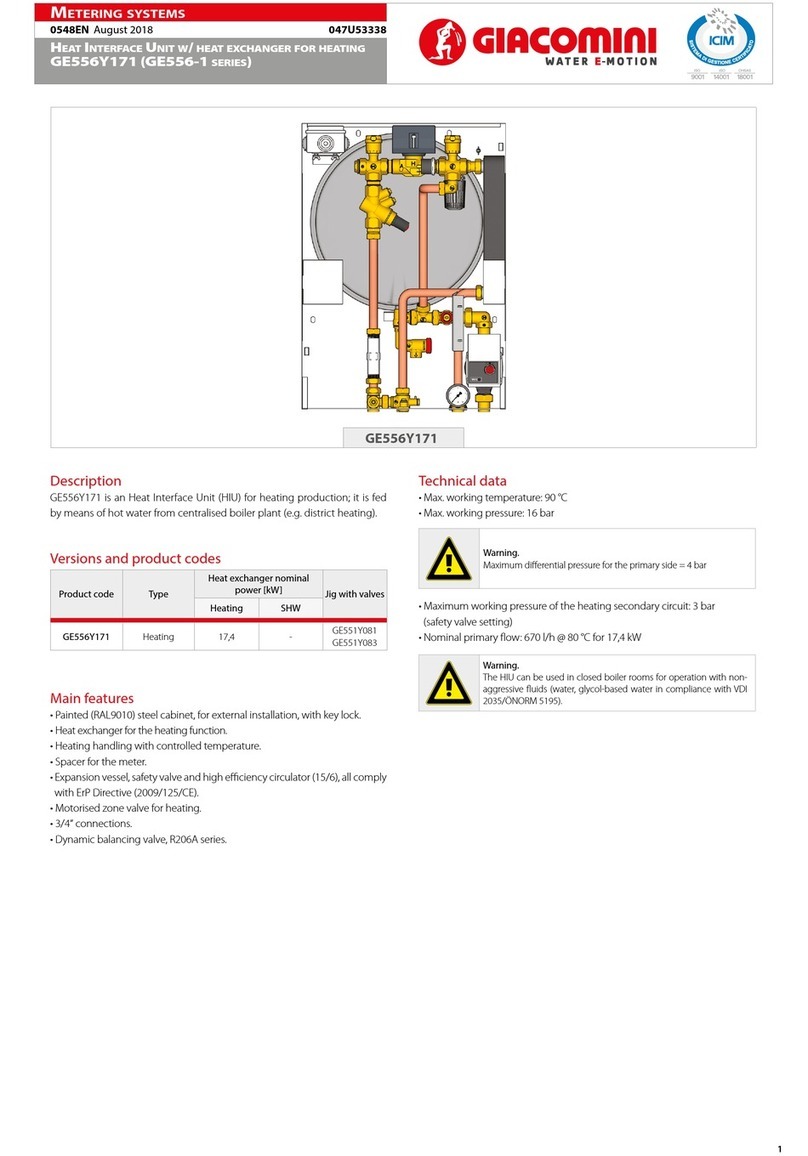

Dimensions

450

450

65 92 55 57 49

157

180

630

180

C

DF

GXY

Legenda

C: Primary outlet

D: Primary inlet

F: Cooling delivery

G: Cooling return

X: Hole for safety valve drain

Y: Hole for electrical cables

Dimensions in mm

Normative references

• UNI EN 1434

• EN 60751

• EN 61107

• Measuring Instruments Directive 2014/32/EU (MID)

• ErP Directive 2009/125/CE

Safety Warning

Installation, commissioning and periodical maintenance of the product must be carried out by qualied operators in compliance with national regulations and/or local standards. A qualied installer must take

all required measures, including use of Individual Protection Devices, for his and others’safety.

An improper installation may damage people, animals or objects towards which Giacomini S.p.A. may not be held liable.

Product Disposal

Do not dispose of product as municipal waste at the end of its life cycle.

Dispose of product at a special recycling platform managed by local authorities or at retailers providing this type of service.

Package Disposal

Carton boxes: paper recycling.

Plastic bags and bubble wrap: plastic recycling.

Additional information

For

mor

e

information,

go

to

www.giacomini.com

or

contact

our

technical

assistance

service:

'+39

0322

923372

6+39

0322

923255

*[email protected]This document provides only general indications. Giacomini S.p.A. may change at any time, without notice and for technical or commercial reasons, the items included herewith.

The information included in this technical sheet do not exempt the user from strictly complying with the rules and good practice standards in force.

Giacomini S.p.A. Via per Alzo, 39 - 28017 San Maurizio d’Opaglio (NO) Italy

IT

AVVERTENZE PER IL CORRETTO SMALTIMENTO DEL PRODOTTO

Questo prodotto rientra nel campo di applicazione della Direttiva 2012/19/UE riguardante la

gestione dei riuti di apparecchiature elettriche ed elettroniche (RAEE). L’apparecchio non deve

essere eliminato con gli scarti domestici in quanto composto da diversi materiali che possono

essere riciclati presso le strutture adeguate. Informarsi attraverso l’autorità comunale per quanto

riguarda l’ubicazione delle piattaforme ecologiche atte a ricevere il prodotto per lo smaltimento

ed il suo successivo corretto riciclaggio. Si ricorda, inoltre, che a fronte di acquisto di apparecchio

equivalente, il distributore è tenuto al ritiro gratuito del prodotto da smaltire. Il prodotto non è

potenzialmente pericoloso per la salute umana e l’ambiente, ma se abbandonato nell’ambiente

impatta negativamente sull’ecosistema. Leggere attentamente le istruzioni prima di utilizzare

l’apparecchio per la prima volta. Si raccomanda di non usare assolutamente il prodotto per

un uso diverso da quello a cui è stato destinato, essendoci pericolo di shock elettrico se usato

impropriamente.

Il simbolo del bidone barrato, presente sull’etichetta posta sull’apparecchio, indica la

rispondenzaditaleprodottoallanormativarelativaairiutidiapparecchiatureelettriche

ed elettroniche.

L’abbandononell’ambientedell’apparecchiaturaolosmaltimentoabusivo della stessa

sono puniti dalla legge.

EN

IMPORTANT INFORMATION FOR CORRECT DISPOSAL OF THE PRODUCT

Thisproductfalls intothescopeoftheDirective2012/19/EUconcerningthemanagement ofWaste

Electrical and Electronic Equipment (WEEE). This product shall not be dispose in to the domestic

waste as it is made of dierent materials that have to be recycled at the appropriate facilities.

Inquire through the municipal authority regarding the location of the ecological platforms to

receivethe productfordisposalanditssubsequentcorrectrecycling.Furthermore,uponpurchase

of an equivalent appliance, the distributor is obliged to collect the product for disposal free of

charge. The product is not potentially dangerous for human health and the environment, but if

abandonedinthe environmentcan have negative impactonthe environment.Read carefully the

instructions before using the product for the rst time. It is recommended that you do not use

the product for any purpose rather than those for which it was intended, there being a danger

of electric shock if used improperly.

The crossed-out wheeled dustbin symbol, on the label on the product, indicates the

complianceofthisproductwiththeregulationsregardingWasteElectricalandElectronic

Equipment. Abandonment in the environment or illegal disposal of the product is

punishable by law.

FR

AVERTISSEMENTS POUR L’ÉLIMINATION CORRECTE DU PRODUIT

Ce produit entre dans le champ d’application de la directive 2012/19 / UE relative à la gestion des

déchets équipements électriques et électroniques (DEEE). L’appareil ne doit pas être jeté avec les

ordures ménagères car il est fait de diérents matériaux pouvant être recyclés dans des centres

appropriés. Renseignez-vous auprès de l’autorité locale concernant l’emplacement des plates-

formes écologiques appropriées pour recevoir le produit pour sa destruction et son recyclage

correct ultérieur. Il convient également de rappeler que, en cas d’achat d’un appareil équivalent,

le distributeur est tenu de collecter le produit à détruire. Le produit n’est potentiellement pas

dangereuxpourlasantéhumaineetl’environnement,maiss’ilestabandonnédansl’environnement,

ilaunimpactnégatifsurl’écosystème.Lisezattentivementlesinstructionsavantd’utiliserl’appareil

pour la première fois. Il est interdit d’utiliser le produit pour un usage diérent de celui auquel il

était destiné, il y a risque de choc électrique si utilisé incorrectement.

Lesymbole delapoubellebarréesurl’étiquettede l’appareilindiquesacorrespondance

produitàla législationrelativeauxdéchetsd’équipementsélectriquesetélectroniques.

L’abandon dans l’environnement de l’équipement ou l’élimination illégale de

l’équipement est punissable par la loi.

DE

WICHTIGE HINWEISE ZUR KORREKTEN ENTSORGUNG DES PRODUKTS

Dieses Produkt fällt in den Anwendungsbereich der Richtlinie 2012/19/EU über die Entsorgung

vonElektro-und Elektronik-Altgeräten(WEEE).DiesesProduktdarf nichtindenHausmüllentsorgt

werden, da es aus verschiedenen Materialien besteht, die in entsprechenden Einrichtungen

recyceltwerdenmüssen.Erkundigen siesichbeiihrerGemeindenachdem Standortdesnächsten

Recyclinghofs bzw. der nächsten Annahmestelle, um das Produkt dem Recycling zuzuführen

bzw. fachgerecht zu entsorgen. Darüber hinaus ist der Händler verpichtet, das Produkt beim

Kauf eines gleichwertigen Geräts kostenlos zu entsorgen. Das Produkt ist für die menschliche

Gesundheit und die Umwelt potenziell nicht gefährlich. Diese können sich aber, falls sie in der

Umwelt gelangen, negativ auf diese auswirken. Lesen Sie daher vor dem ersten Gebrauch des

Produkts die Inbetriebnahme-, Bedienungs- und Entsorgungsanweisungen sorgfältig durch.

Es wird empfohlen, dass Sie das Produkt nur für den vorgesehenen Zweck verwenden. Bei

unsachgemäßer Verwendung bzw. Fehlgebrauch besteht die Gefahr eines elektrischen Schlags.

Das Symbol der durchgestrichenen Mülltonne auf dem Etikett des Produkts weist auf

dieKonformitätdiesesProduktszudenVorschriftenfürElektro-undElektronik-Altgeräte

hin. Das Ablagern in der Umwelt oder die illegale Entsorgung des Produkts ist strafbar.