Ⅶ. Maintenance

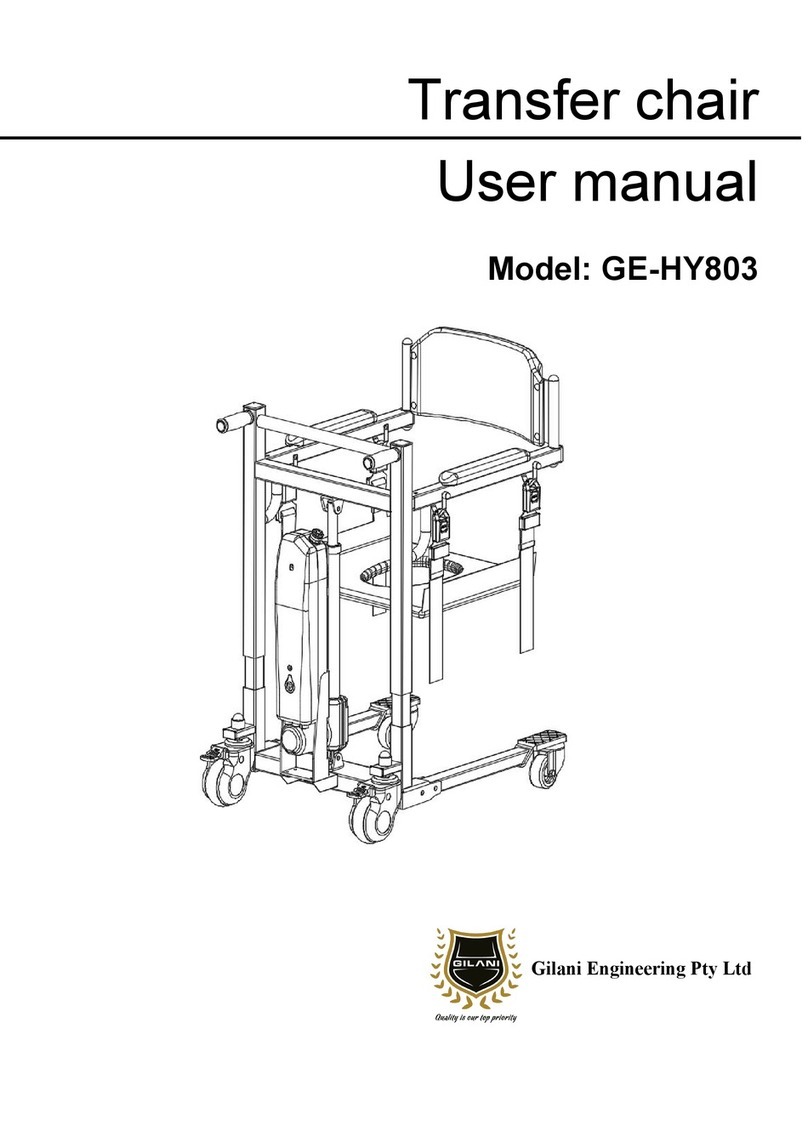

For safe operation, please check and test before use.

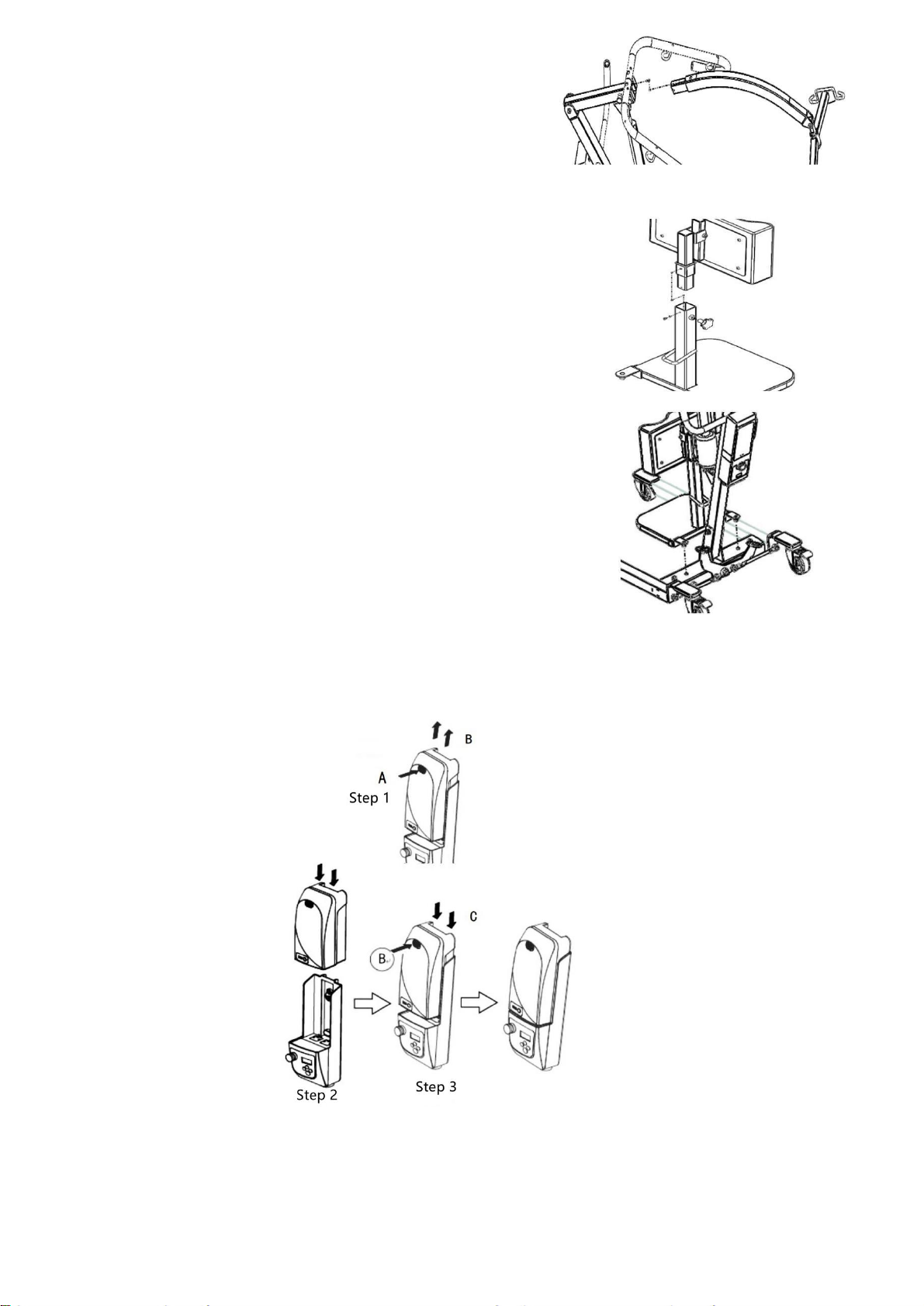

1. Check that the screws and fixing nuts on the boom are tight;

2. Check control handle, lift and width adjustment movement;

3. Check the emergency drop function(electric and manual);

4. Check that the safety hook on the boom is normal.

Attention! Chemical substances containing phenol and chlorine should not be used to wipe the shift

machine, which will damage the plastic powder and plastic materials.

Transportation and Storage

When the device is not used for a long time, press the stop button. Storage ambient

temperature above 0℃, normal relative humidity (≤60 )

Inspect

Have a complete checkup at least once a year. Pay special attention to areas where wear occurs,

such as joints, bolts, etc.

Ⅷ. Trouble Shooting

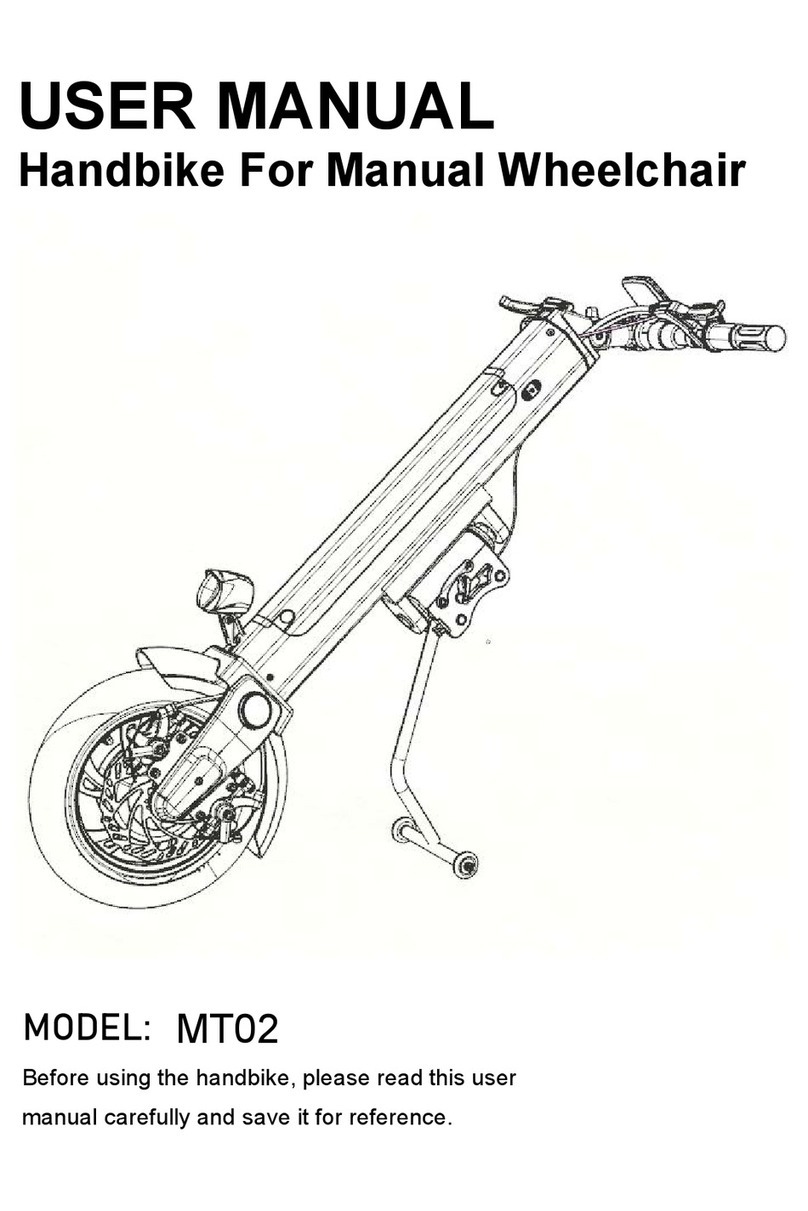

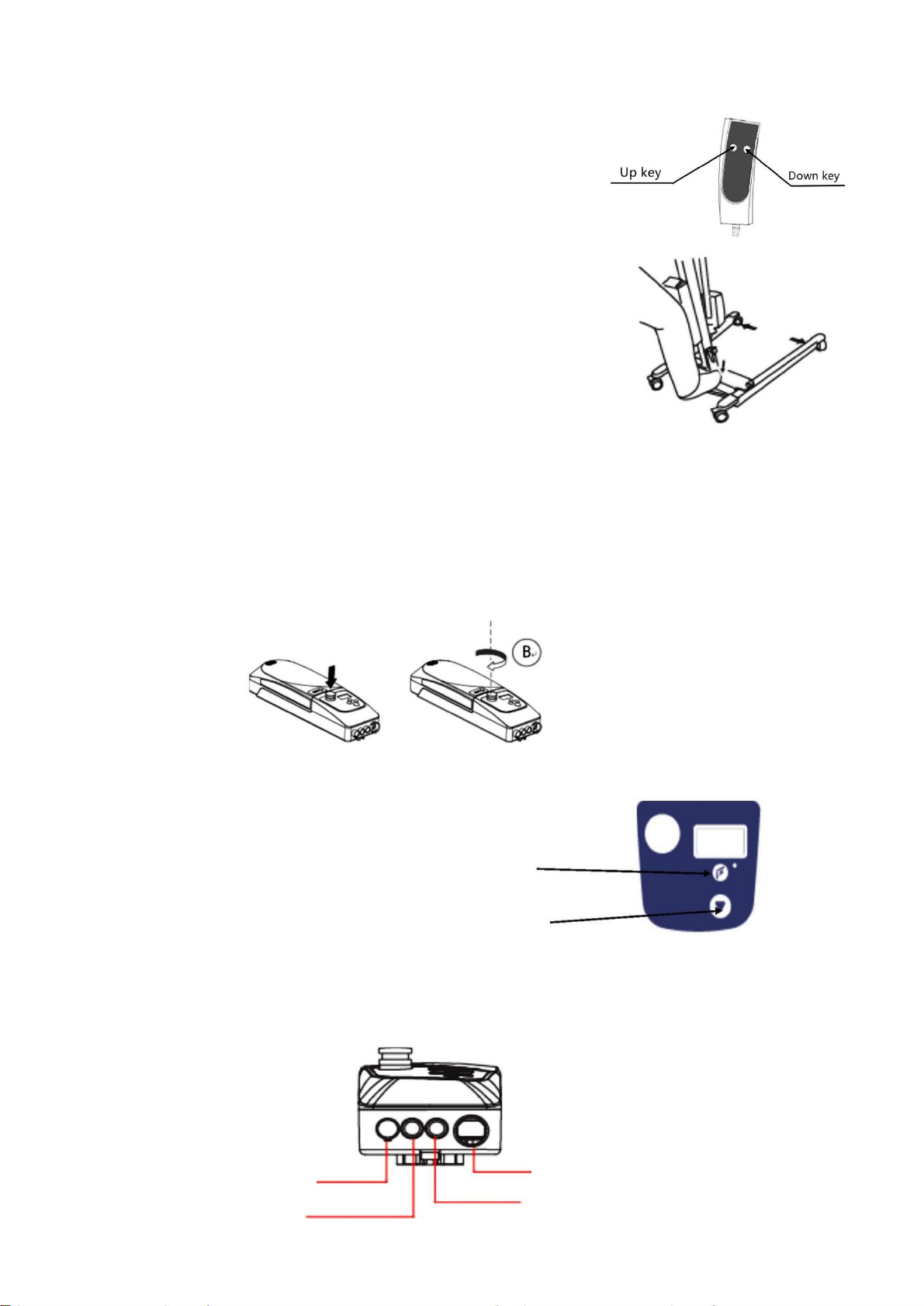

1. Check whether the emergency stop button is pressed

2. Check whether the wire of is connected correctly

3. Check battery power

4. Check whether the battery contact panel has problems or damages

5. If the electric shift machine is not working, please contact the

after-sales service

1. Check whether the charger is plugged into the socket

2. Check the battery contact panel for problems or damage

3. If the charger still does not charge, please contact after-sales

service

1. Check whether the emergency stop button is pressed

2. Use an emergency descent device

3. If the electric shift machine is not working, please contact the

after-sales service.