Table of Contents

Updated 1/12/23

INTRODUCTION 1

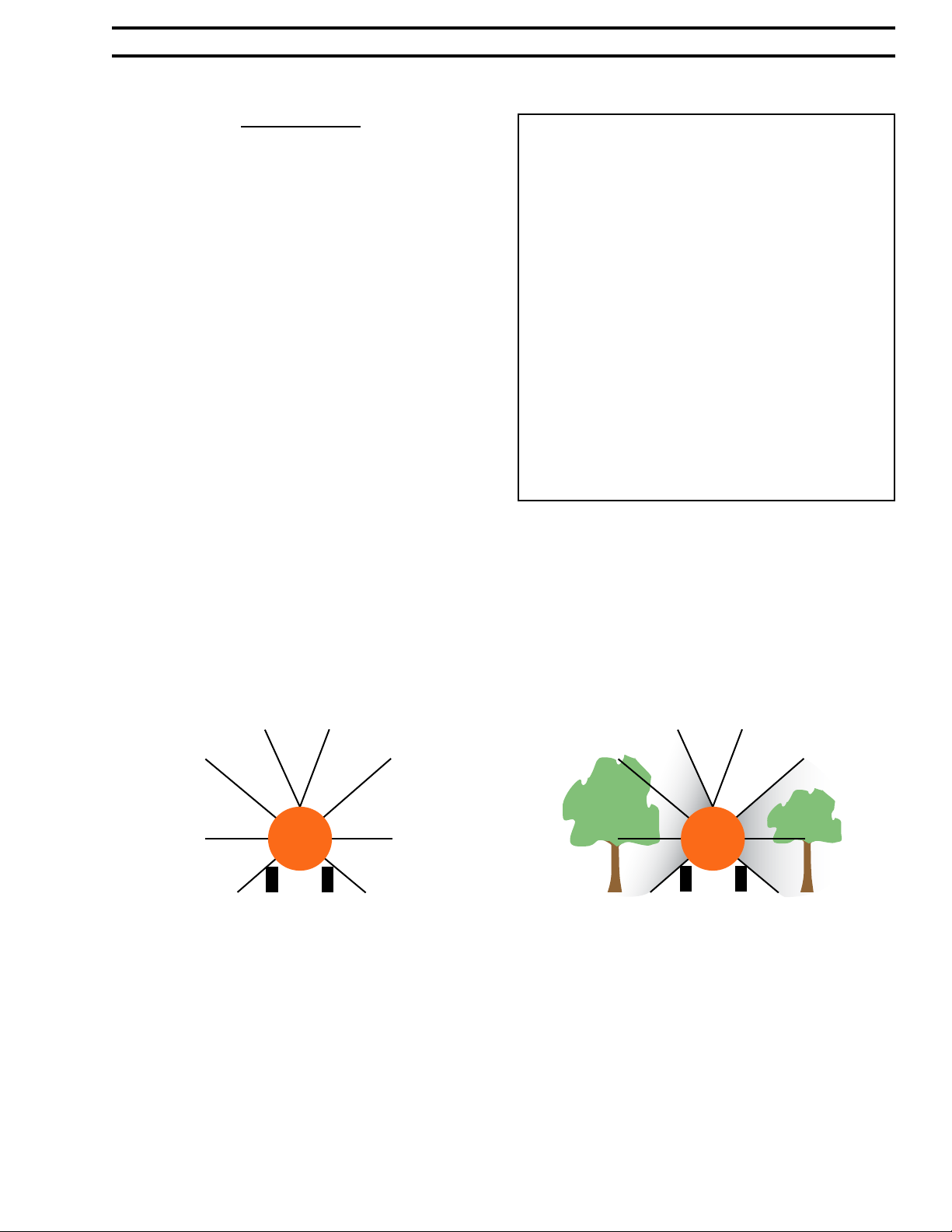

About Sonic Spray’s Zones 1

OPERATOR INTERFACE DISPLAY 2

Overview of Sonic Spray’s Operator Interface 2

OPERATION 11

MAINTENANCE 12

Basic 12

Maintenance of Solenoid Valves 13

Winterizing 12

INSTALLATION ON TRACTOR 14

KIT INSTALLATION ON SPRAYER 15

Display Controller CAN Tool 19

Front of Sprayer Electrical Connecons 22

Speed Sensor and Parts 20

Speed Sensor Harness to Main Connecon 21

Ultrasonic Electrical Connecons 16

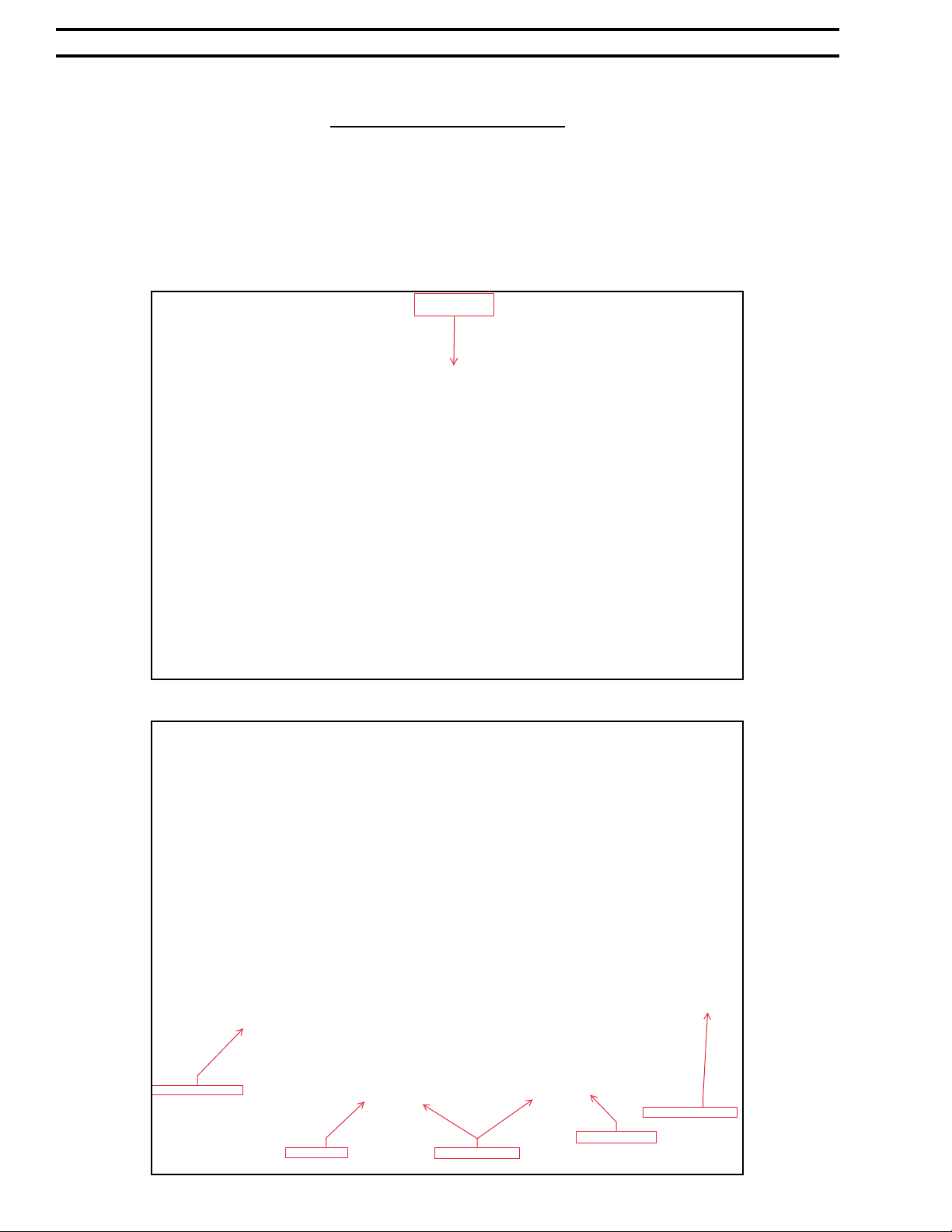

Valve Installaon 18

Valve Mounng Reference 17

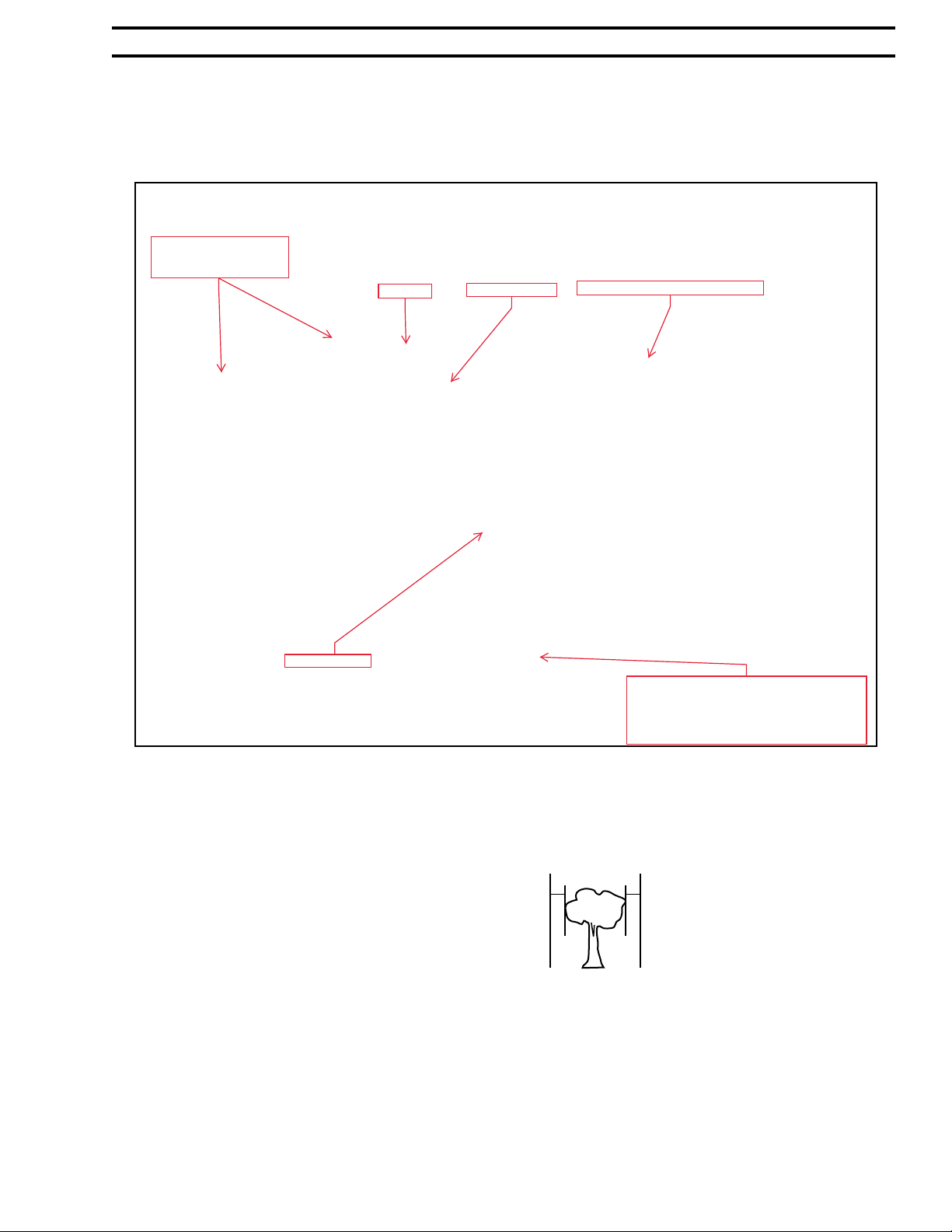

Zone Diagram 15

TROUBLESHOOTING 23

Ground speed not working 23

No Sync Warning 24

Power ON Status 23

Power to control on green light illuminated but display not

working 23

Sonic Spray will not power up 23

Target Indicator Funcons 24

Target Status & Near MIN 23

Ultrasonic 1 not working 23

Ultrasonics 23

Valve not opening 23

Valve not shung o 23

ELECTRICAL 25

Baery to Controller 32

Harness Display to Controller 29

HARNESS, VALVE 6 ZONE FOR AIR-O-FAN ENGINE DR 30

HARNESS, VALVE 8 ZONE FOR AIR-O-FAN ENGINE DR 31

Power Supply 25

Speed Sensor 28

Ultrasonics 26

Valve Harness Sprayer, 6 Zone 33

Valve Harness Sprayer, 8 Zone 34

Valve Harness Sprayer to Control 35

Valves 27

PARTS 36

ASCO Valves & Repair Kit GTS 11006 39

Baery Connecon Parts 46

Clamps 36

Display Controller and Parts 44

Harnesses 42

Harness, Proximity & parts 43

Mount for Display Controller and Parts 45

Rears Front Panel and Parts Reference 50

Rears Front Panel and Parts Reference connued 51

Sensors for 50 Long Range Sonic Spray 38

Sensors for Standard Range Sonic Spray 37

Sonic Spray Main Enclosure 47

Speed Sensor and parts 49

Tork Valve & DIN Harness GTS 11350 40

Tork Valve Repair Kit 41

Wheel Speed Assembly 48

GVF WARRANTY 52