6GIROVAP - USER’S GUIDE

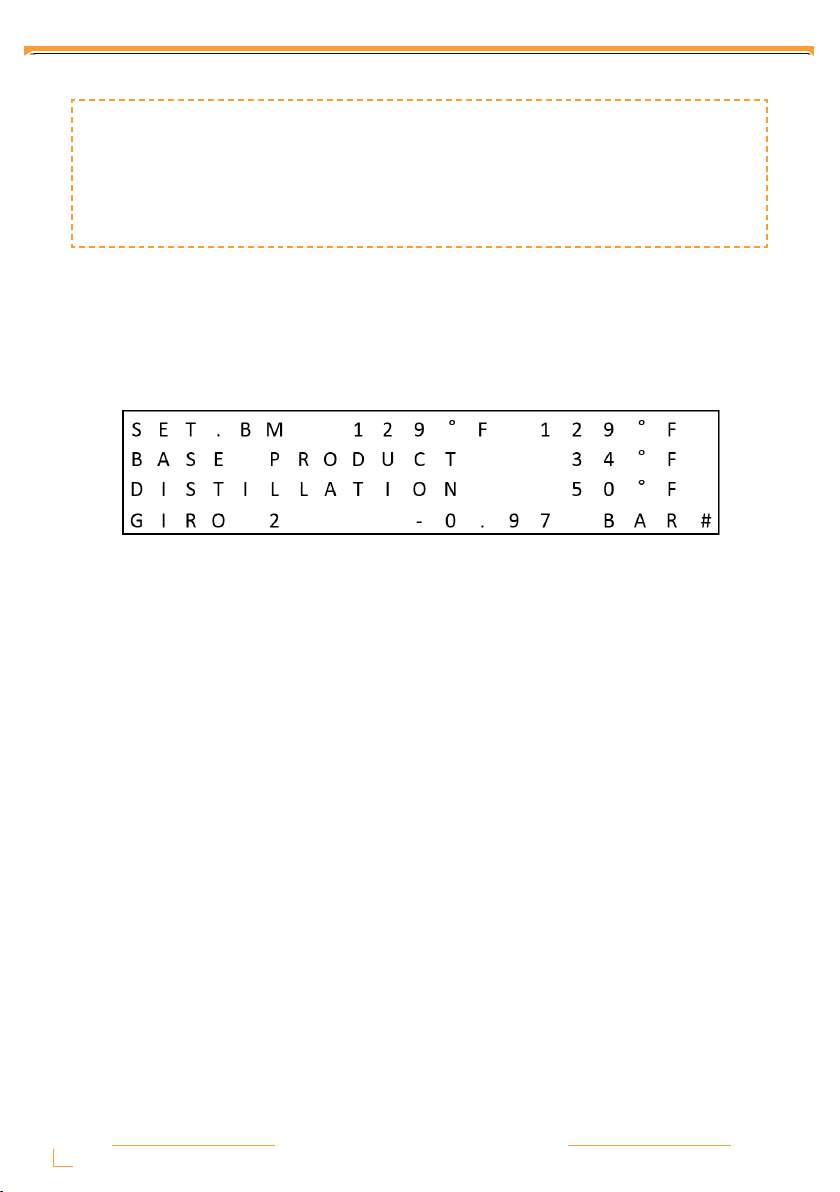

Girovap is equipped with a double-bodied

diaphragm vacuum pump that achieves a

suction of 15 litres/minute. Thanks to its two

independent heads, although joined by a

patented system, it allows to reach a vacuum

level comparable to the best piston and oil

bath vacuum pumps. Girovap is equipped with

an EAD pump that guarantees to reach -0.97

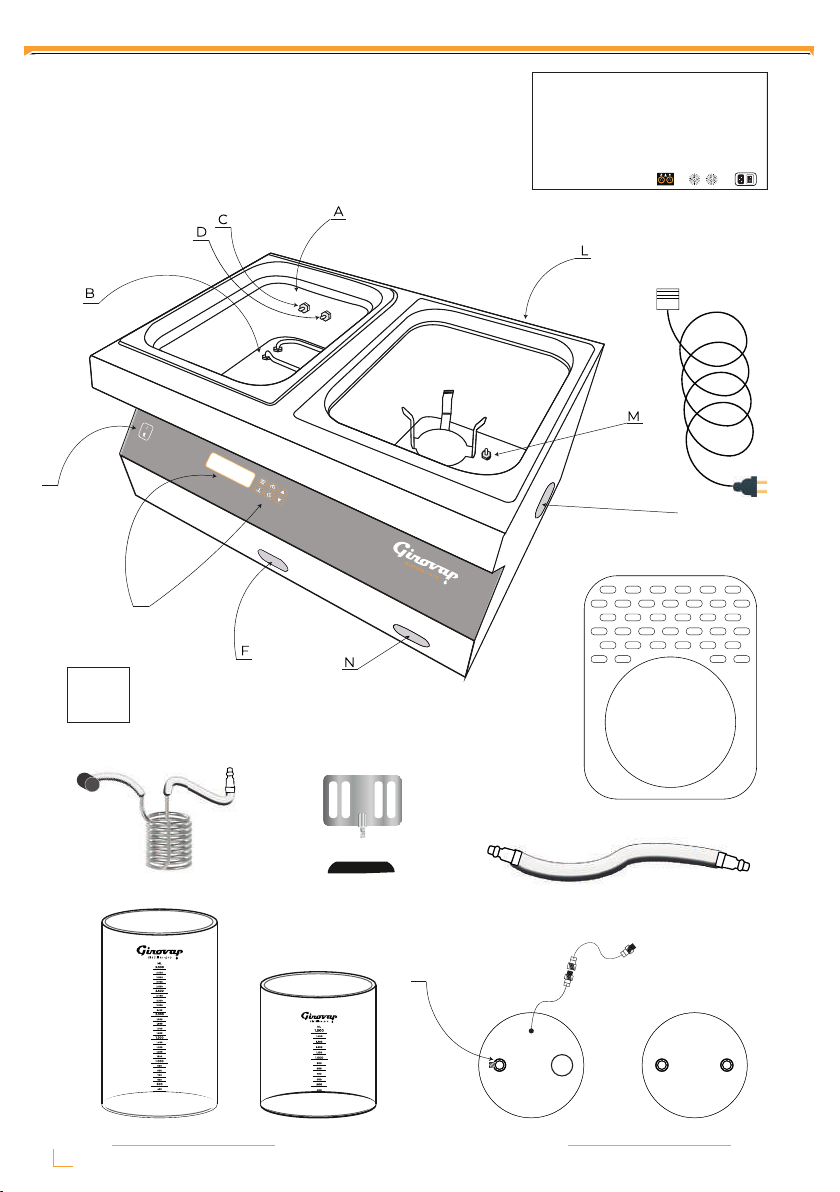

Know which are the three parts of GIROVAP that

make it totally different from laboratory Rotovapors

Membrane vacuum pump

Distilling glass

Conventional Rotovapors have a glass where

the main ingredient is put, this glass is called

a ask. In the tabletop units, the capacity

of the ask is usually between 2 liters and

in very special cases they reach 3 liters.

By rotating the product inside it to increase

the evaporation area, manufacturers are

limited to being half loaded, so its capacity is

reduced to 50%.

Girovap cups do not rotate, so they can be

loaded up to 75% of their real capacity.

Girovap can work with 2.5 liters of product in

its 3-liter cup, or up to 3.5 liters in the 5-liter

accessory cup. Its lid is totally hermetic, and

since no vacuum sealing element is rotated,

bar at room temperature. (Relative Pressure)

As it is a diaphragm pump, it does not require

continuous maintenance.

Its membrane and head system allows any

humidity that may escape during distillation to

escape. We have a video to help you maintain

it for your technical service.

there are no seals or small leaks due to the

wear and tear of materials due to rotation,

so the vacuum level will always be the same

even after years. In addition, the vacuum

level is always stable and by working without

loss we can perform much more delicate

distillations.

The lid itself has a temperature probe that

measures the exact temperature of the steam

and the product before it leaves the glass.

Its control tap allows to regulate the vacuum

level and can be used to introduce more liquid

into the glass without interrupting the process.

In addition, the interior of the cup allows for

1

2