7

GA8701871 REV 00 JANUARY 2023

Important Information – Foreword 1

About this Manual

This manual provides instructions for some

items requiring assembly on delivery, setting

up instructions, calibration procedures, pre-

operation requirements, operating instructions

and maintenance requirements to achieve the

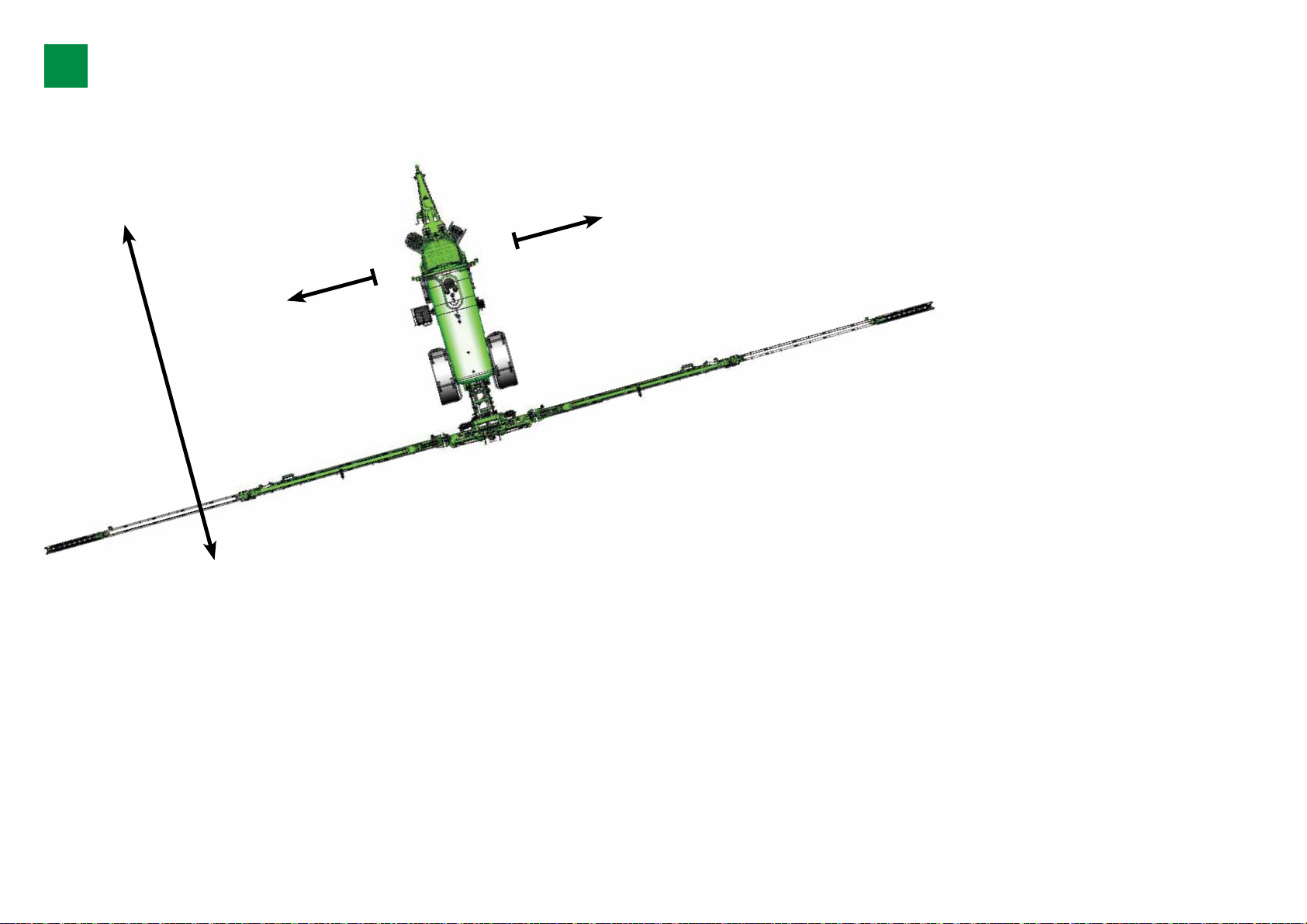

best performance of this Prairie Special Series

2 Trailed Sprayer.

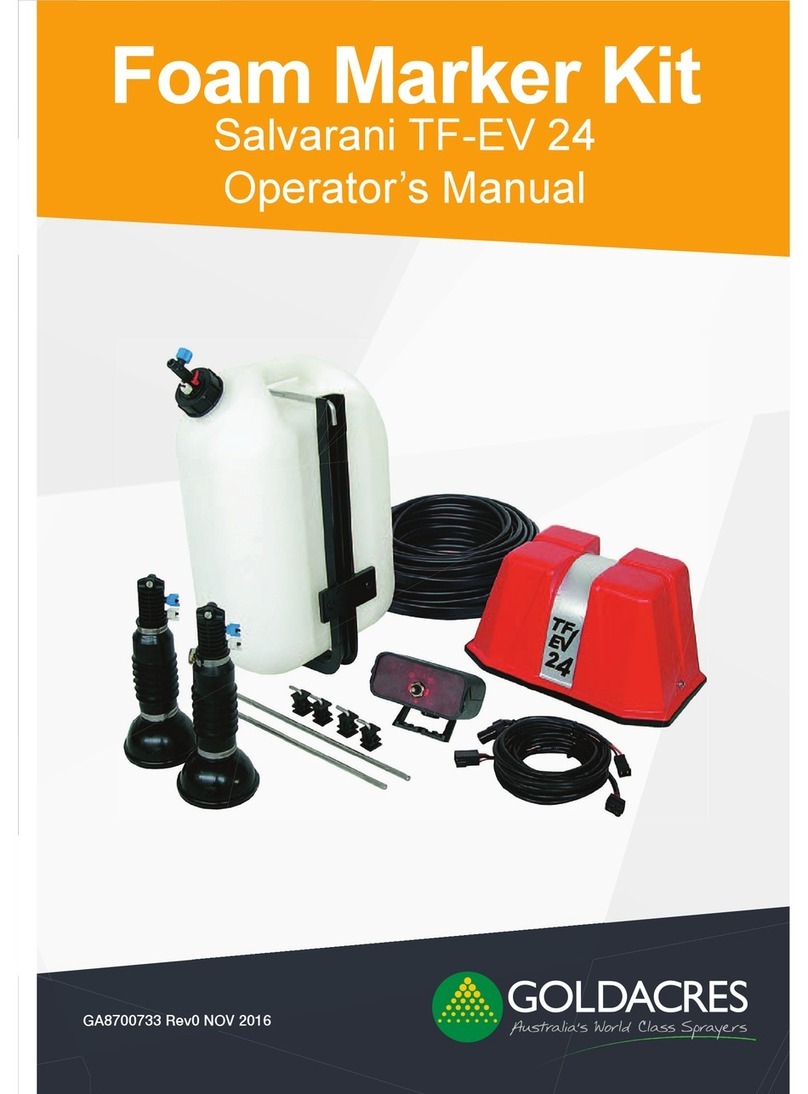

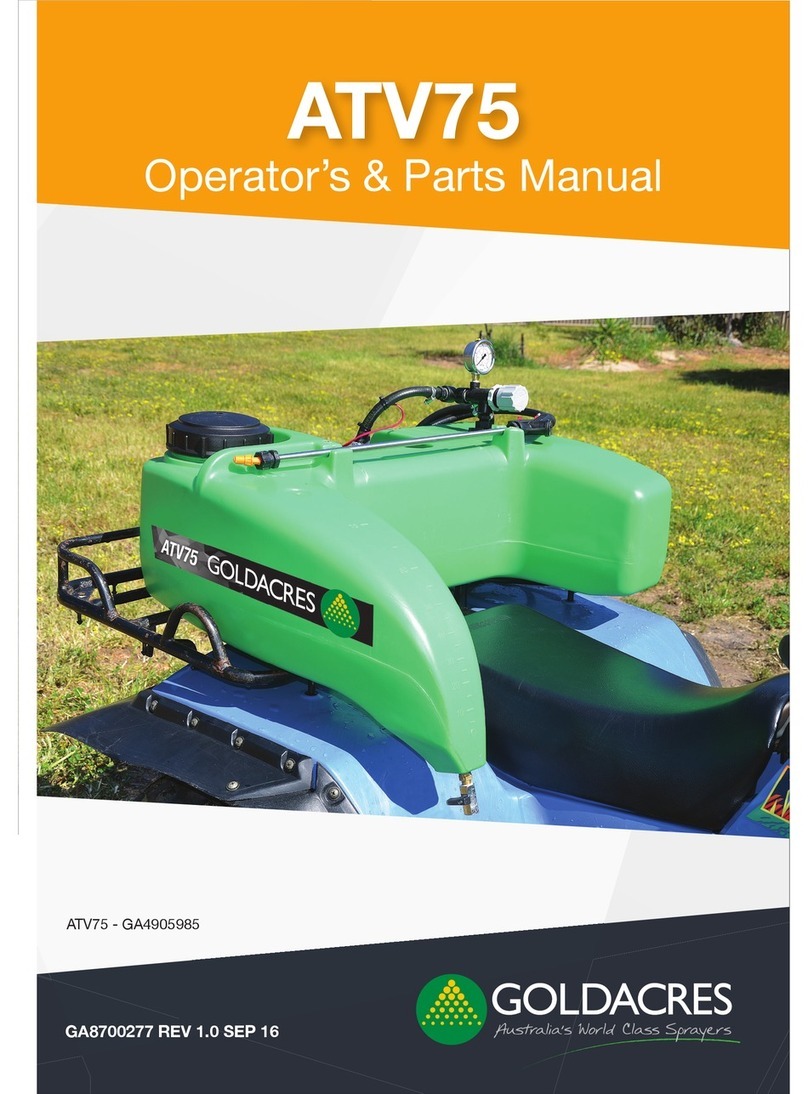

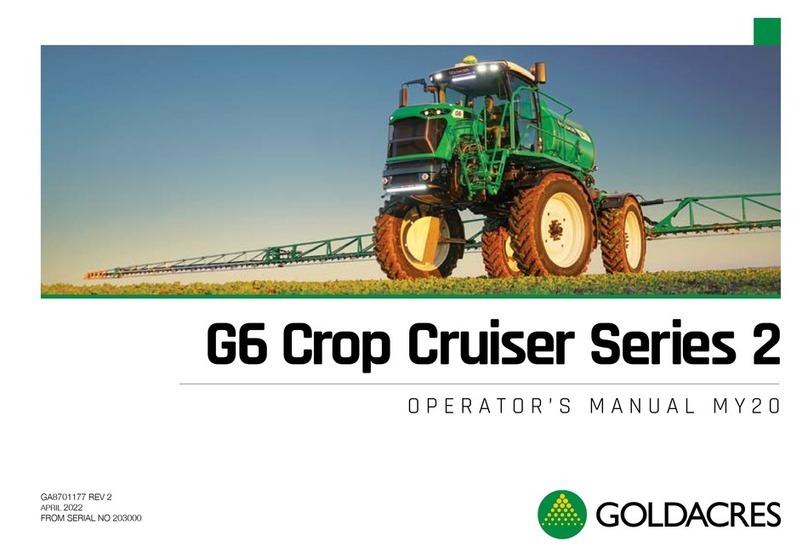

Some options explained in this manual may

not be installed on your sprayer. Other options

fitted may require another operator manual for

instructions.

Please ensure this manual and other relevant

manual are passed onto the new owner if the

sprayer is sold.

How to Use/Read this

Manual

This manual includes a Contents page and 10

Chapters - with each Chapter beginning with

a list of Headings & Subheadings.

Each page contains written instructions

with pictures, illustrations, decal & symbol

instructions, above & below providing visual

support and information to each instruction.

Numerical values & settings shown in the

manual are instuctional examples only and

may not be representative for your machine or

local situation.

• Conveys risk of injury highlighting the need for action

to be taken to protect personal health.

• Serious injury may occur if you don’t follow

instructions!

• Conveys the potential for personal injury and/or

damage to the machine itself.

• Injury and/or damage your machine, if you don’t follow

instructions!

• Conveys useful operating information and procedures.

• It is not hazard related.

Decal/Symbol Instructions

Danger, Warning, Caution & Note symbols & decals are used throughout this manual and on your

Prairie Special Series 2 Trailed Sprayer instructing you of risks, procedures & operator safely.

It is important to familiarise yourself with these & understand their meaning to be able to quickly

identify risks, procedures, operator safety & safety of others, as outlined below:

• Conveys highest risk of injury or death to convey that

action must be taken to protect personal health.

• Serious injury or death may occur if you don’t follow

instructions!

• Danger Symbol - used for areas

where the highest personal risk of

injury or death is present.

Always read the information on these

decals andensure you are taking the

precautions necessary to prevent risk

of injury or death.

You may be killed or seriously hurt if

you don’t follow instructions!

• Caution Symbol - used where there

is potential for personal injury and/or

damage to the machine itself.

Injury and/or damage your machine

may occur if you don’t follow

instructions

• Note Symbol - is used to inform the

operator of installation, operation or

maintenance information & procedures

that are important for the best ways of

operating this sprayer.

The Note symbol is not hazard related.

• Warning Symbol - used in areas

where there is potential for risk or injury

highlighting the need for action to be

taken to protect personal health.

You can be seriously hurt if you don’t

follow instructions!

Operator Responsibilities

All operators of the Prairie Special Series 2

Trailed Sprayer should be adequately trained

in the safe operation of this equipment.

It is important that all operators have read and

fully understand the operator’s manual prior to

using this equipment.

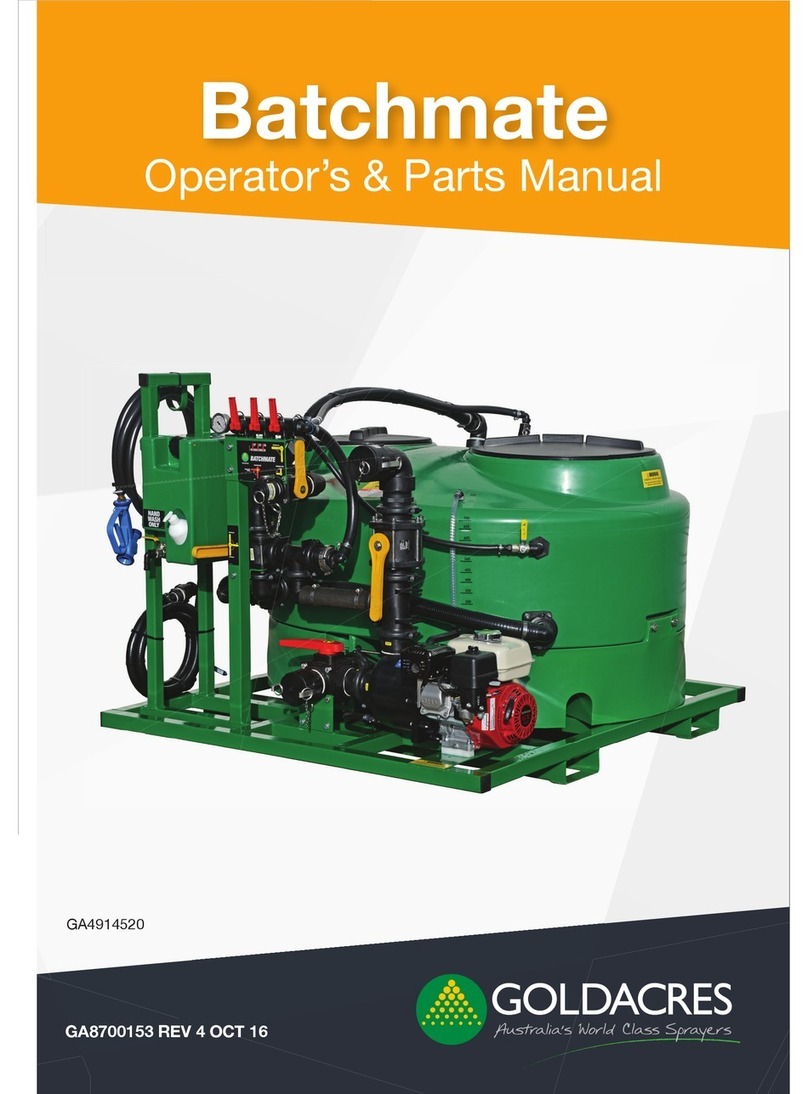

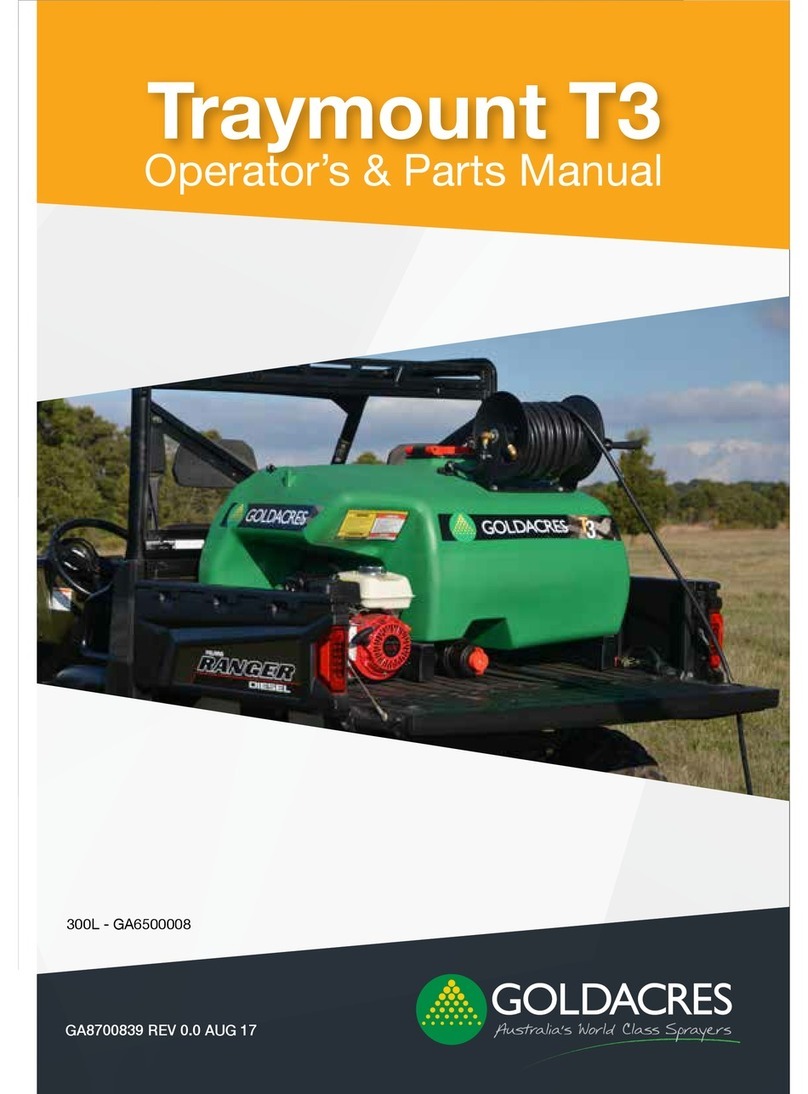

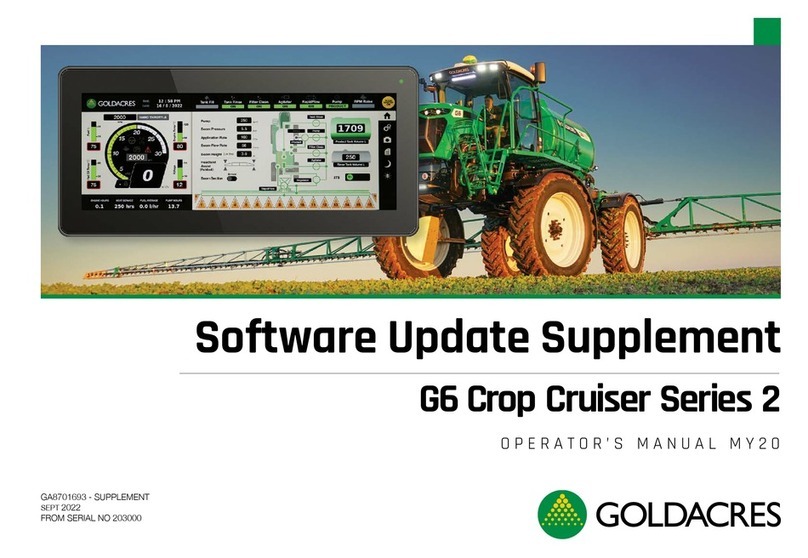

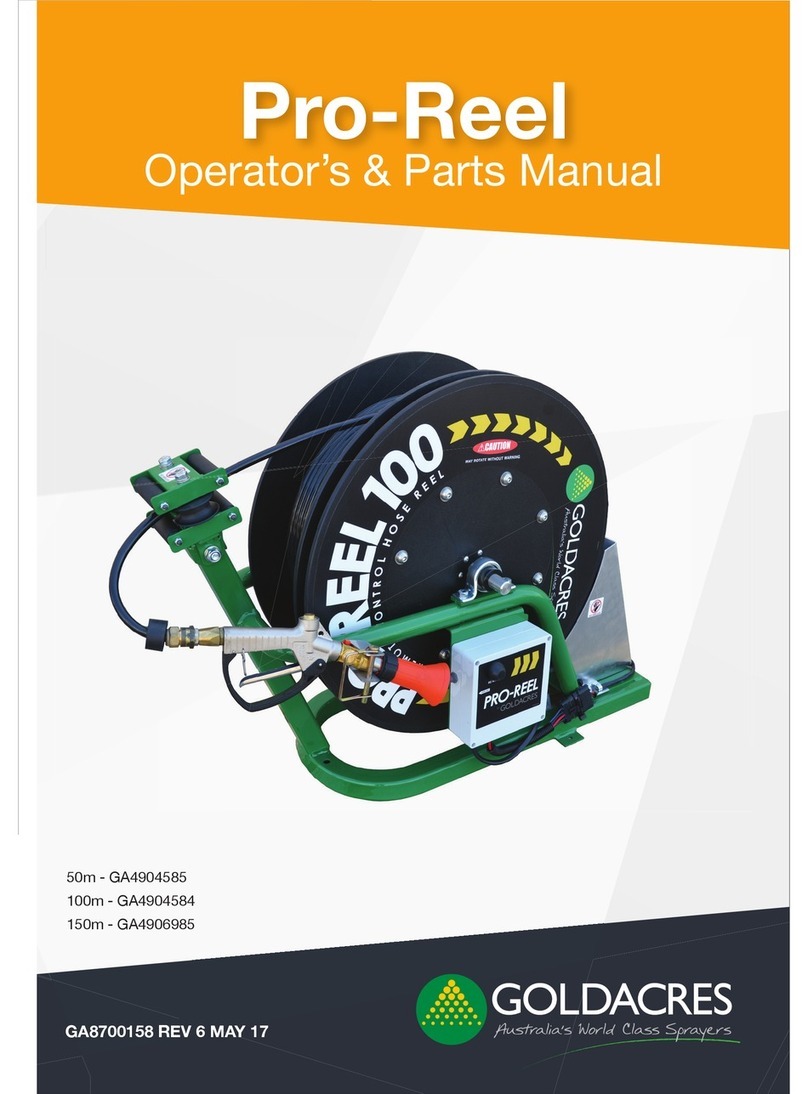

All operators of the Prairie Special must read

all Operator Manuals for this machine

including but not limited to:

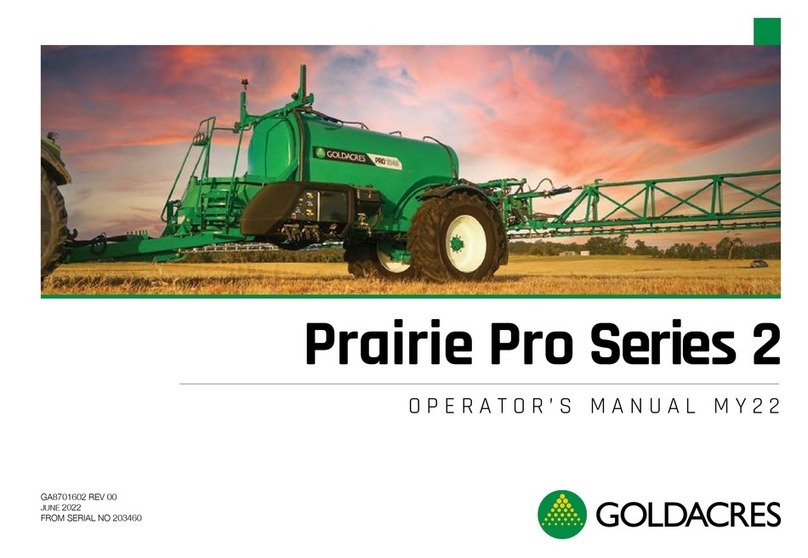

• This Prairie Special Series 2 Operators

Manual

• Delivery & Warranty Registration

Manual

• Prairie Special Series 2 Parts Manual

(available online only).

• Raven Rate Control Module

Operation Manual

• Other Manuals as required,

and fully understand:

• All risks & safety concerns

• Installation & assembly

• Pre-operation checks

• Calibration of the sprayer

• Operating the sprayer

• Sprayer lubrication & maintenance

• Use of protective clothing

• Risks of using chemicals & spraying.

All new operators should be trained in an

area without bystanders or obstructions and

become familiar with the sprayer prior to

operation.