DV-2-MET / DV-AV-MET 10/1/2013

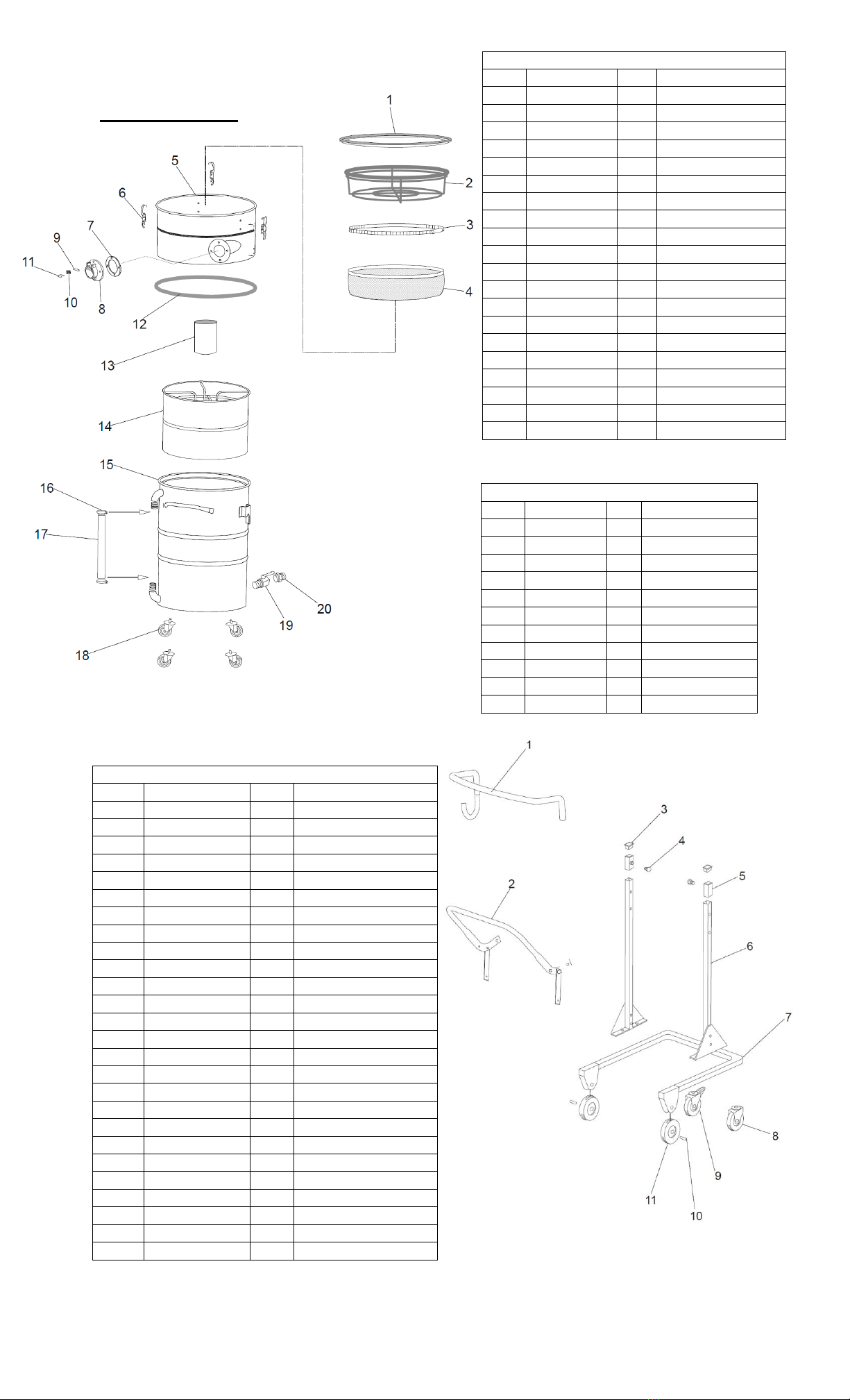

SET-UP

1. Remove from packaging and inspect unit. Report any discrepancies to Goodway

Technologies Corporation’s Customer Service at (800) 370-2855.

2. Position this vacuum cleaner in the area it will be used.

3. Ensure all filters are in place including the nylon filter (located under the motor head) and

the chip basket (located in the detachable collection tank).

4. Attach hose to the intake manifold.

For Electric Powered Vacuums:

Connect the unit to the plant’s wiring. See units name plate for power requirements. It is

imperative that the ground connection is properly made. See grounding instructions for more

information. Unit is now ready for operation.

For Pneumatic Powered Vacuums:

A clean, dry supply of air at a minimum of 50 PSI at 35 CFM is required for operation. The

maximum allowable pressure is 90 PSI at 50 CFM.

WARNING –unrestricted compresses air hoses can whip, causing personal injury and

equipment damage.

Use a ½air line minimum, smaller air lines will restrict flow and lessen performance.

Connect a grounded air supply line to the barbed fitting at the intake on the vacuum lid. Make

sure the valve on the lid is in the off position. Unit is now ready for operation.

OPERATION

During operation regularly check the liquid level in the level indicator located on the front of

the collection tank. When the collection tank is full, the floating device will stop the air flow.

The motor(s) will continue to run, but suction ends. At this point it is necessary to empty the

collection tank.

For Electric Powered Vacuums:

Switch on the vacuum motor by activating the vacuum motor switch. The motors are each

controlled by a switch on the vacuum head. Both motors are on for normal operation but one

motor at a time can be used to decrease air flow.

For Pneumatic Powered Vacuums:

Open the valve on the vacuum lid to the desired setting and begin vacuuming. When finished

vacuuming, always shut off the main air supply and open the valve at the vacuum to relieve

pressure in the air line.

The debris collection tank has a coolant level indicator. Empty the liquid from the tank by using

the dump valve on the rear of the tank.

To Empty Debris Collection Tank:

To release the debris container, pull the lever on the chassis up (see figure). The container is

now unlocked and easily transportable for emptying.

CAUTION - The chip basket when full will be heavy. Use extreme caution.

Ensure the float, the cylindrical part in the middle of the chip basket, is not discarded during

emptying.

When the container has been emptied, put it in its initial point under the filter chamber and

make sure that it is correctly arranged. Pull down the release lever and the container will be

automatically lifted and locked in place. At this point the vacuum cleaner is ready to be used.