CTV-1501 0220

2

CONTENTS:

GENERAL ............................................................................................................................................... 3

IMPORTANT SAFETY INSTRUCTIONS............................................................................................ 3-4

SPECIAL SAFETY POINTS ....................................................................................................... 4

GROUNDING INSTRUCTIONS................................................................................................ 4

GROUND FAULT CIRCUIT INTERRUPTER PROTECTION ......................................................... 4

EXTENSION CORDS............................................................................................................... 5

CAUTIONS ............................................................................................................................. 5

ELECTRIC MOTOR ................................................................................................................. 5

SET-UP ................................................................................................................................................. 5-6

PRIMING / OPERATION ........................................................................................................................7

MAINTENANCE .....................................................................................................................................8

COLD WEATHER STORAGE .................................................................................................................8

TROUBLESHOOTING............................................................................................................................8

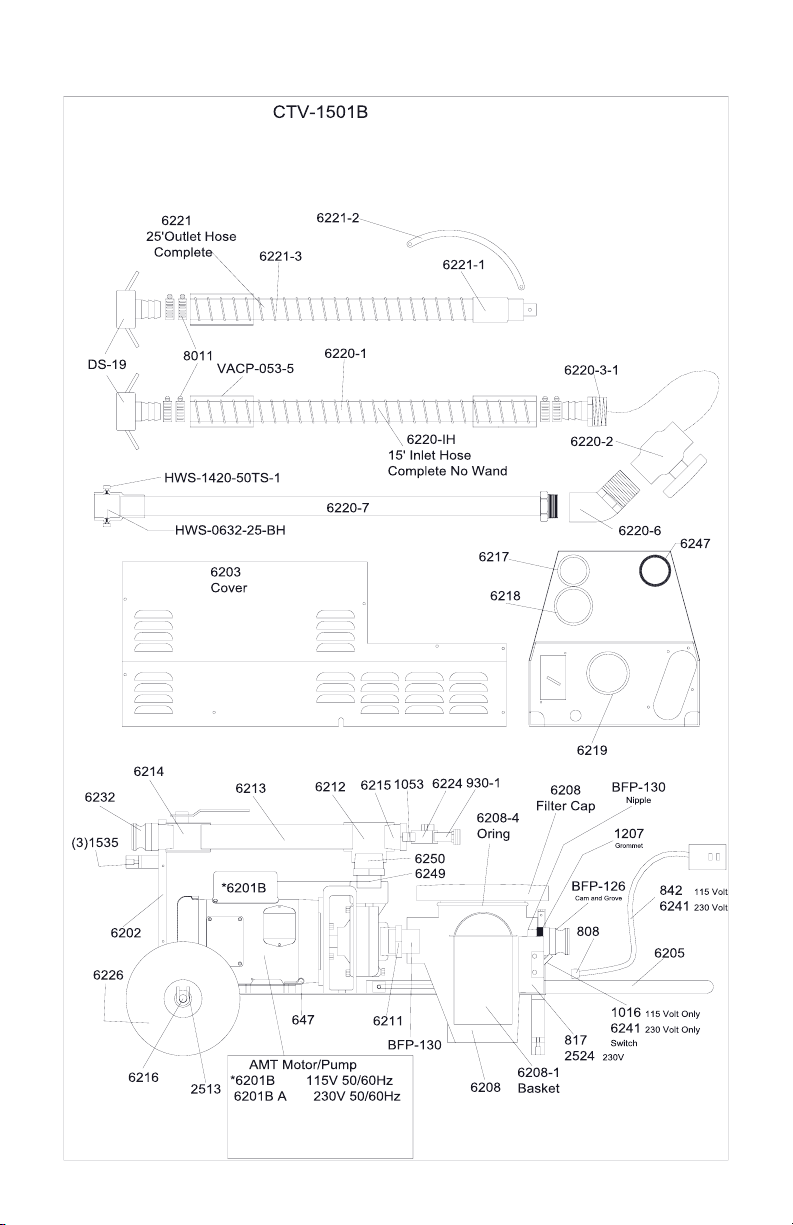

CTV-1501 ASSEMBLEY DRAWING ......................................................................................................9

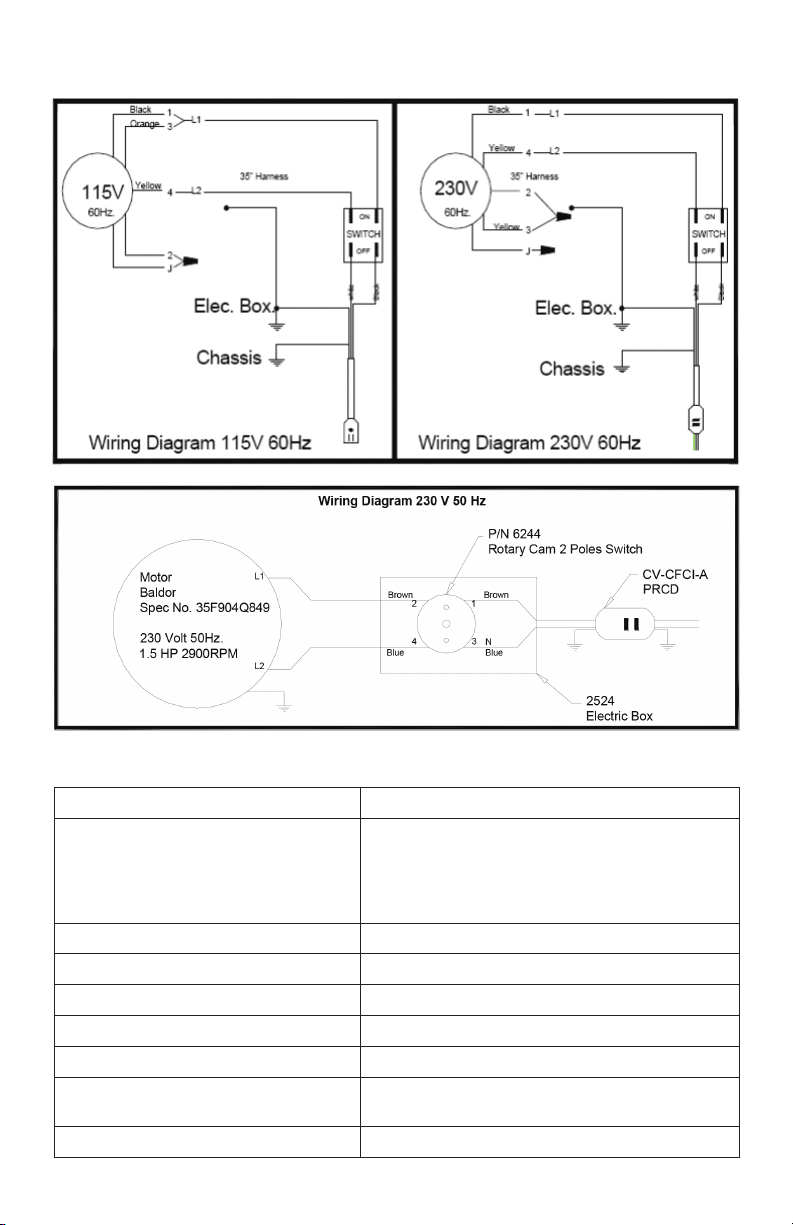

CTV-1501 WIRING DIAGRAM ............................................................................................................10

TECHNICAL DATA ...............................................................................................................................10

NOTES...................................................................................................................................................11

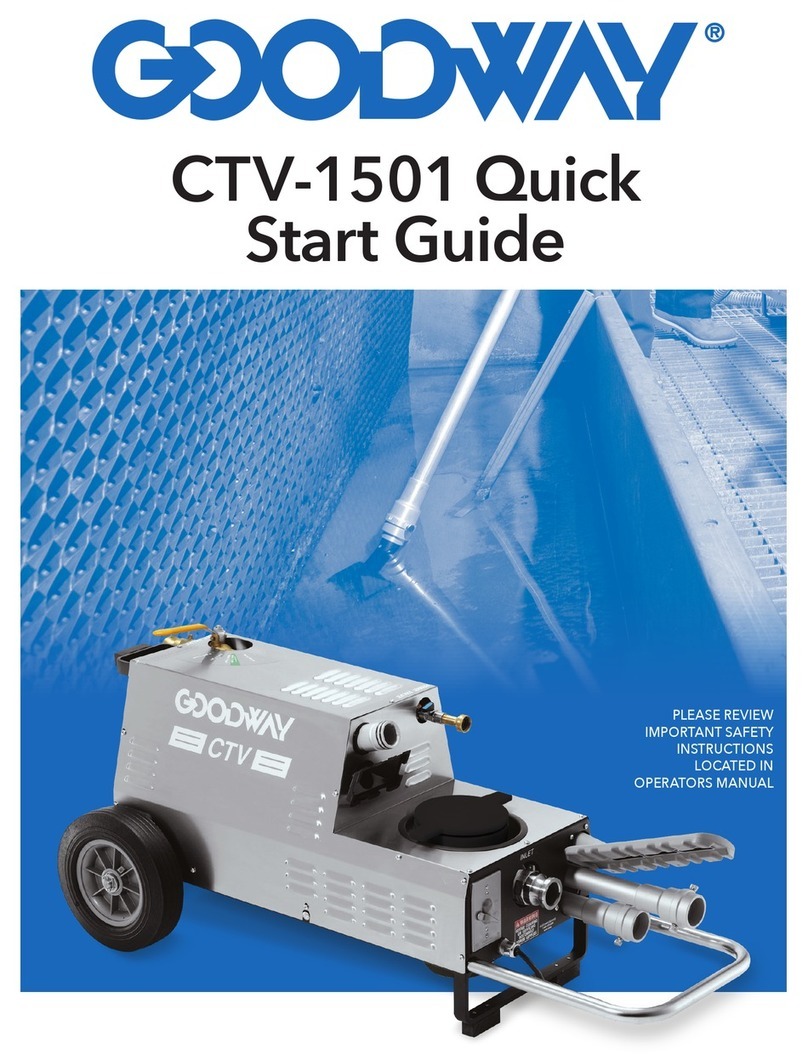

Thank you for purchasing this Goodway Cooling Tower Vacuum. We appreciate

your business and look forward to serving you in the future. As with all Goodway

products, you can be assured that the nest quality components and workmanship

have gone into this machine.

Please take a few minutes to read the following Operating and Maintenance

Instructions. By carefully following the instructions, you will obtain years of

trouble free service from this product. Please pay particular attention to the safety

instructions and exercise caution when using this machine.

GOODWAY®TECHNOLOGIES CORPORATION

HVAC & FACILITY MAINTENANCE SOLUTIONS

Call Us: +1-203-359-4708

For Sales Call: 1-800-333-7467

For Service Call: 1-800-370-2855