7

DV-CNC /DV-CNC3 032917

INSTALLING THE MACHINE (SET-UP)

1. Remove from packaging and inspect unit. Report any discrepancies to Goodway

Technologies Corporation’s Customer Service at (800)-370-2855.

2. Position this vacuum cleaner in the area where it will be used. Make sure to use

the wheel locks located on the casters.

3. Connect the unit to the plant’s wiring ( see units name plate for power

requirements). It is imperative that the ground connection is properly made. See

grounding instructions for more information.

4. For the DV-CNC3 model only, test that the motor is wired properly (it can turn

backwards) by briefly starting the motor by pushing the motor starter switch and

turning it off. Then either observe the direction of the motors cooling fan, which

is on top of the motor, in relation to the arrow on the casting or test the air

coming out of the exhaust stack (it should be blowing out).if the motor is turning

in the wrong direction, remove power from the circuit and reverse two of the

legs of the three phase wiring. Reassemble the wiring.

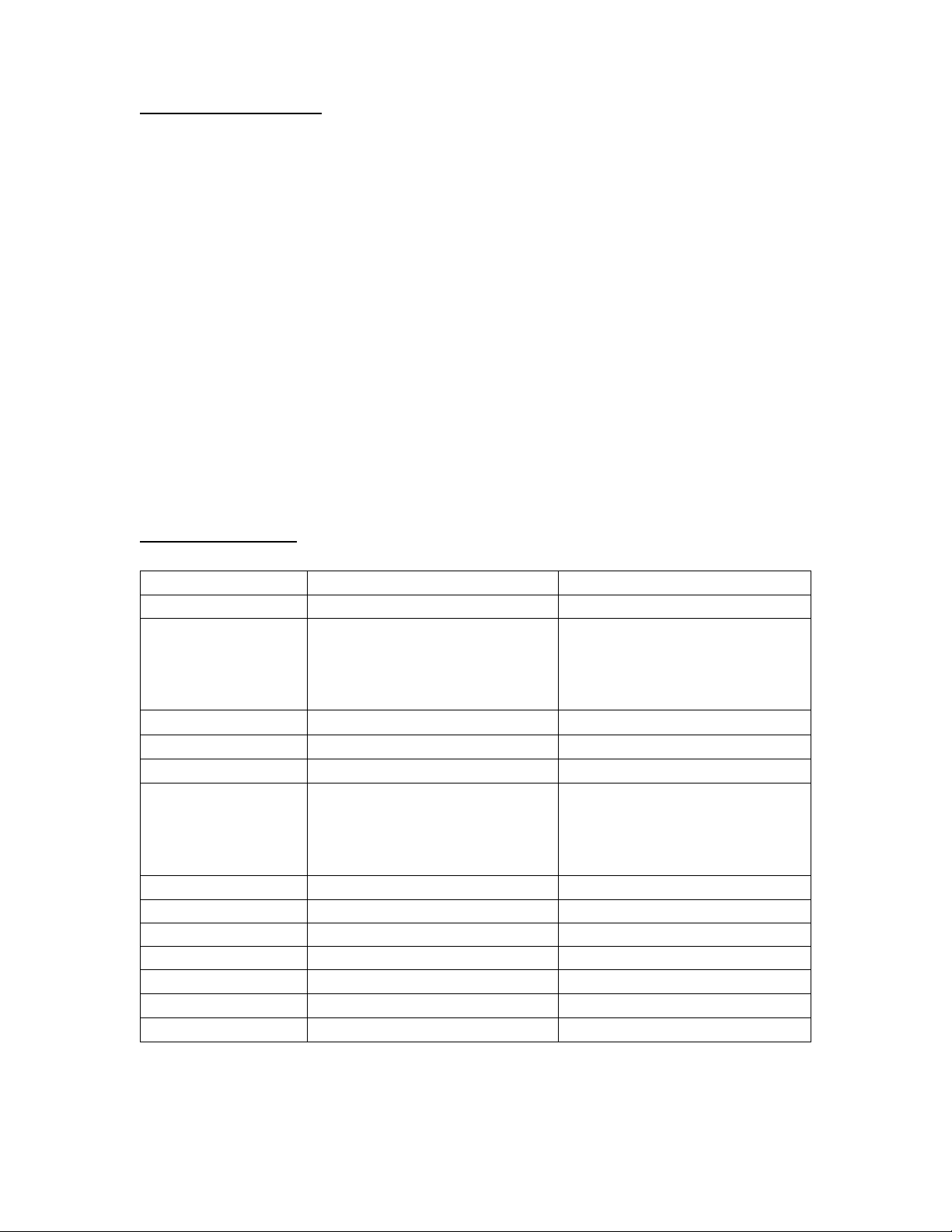

5. Prime the discharge pump, never run the pump dry. See priming instructions for

more information.

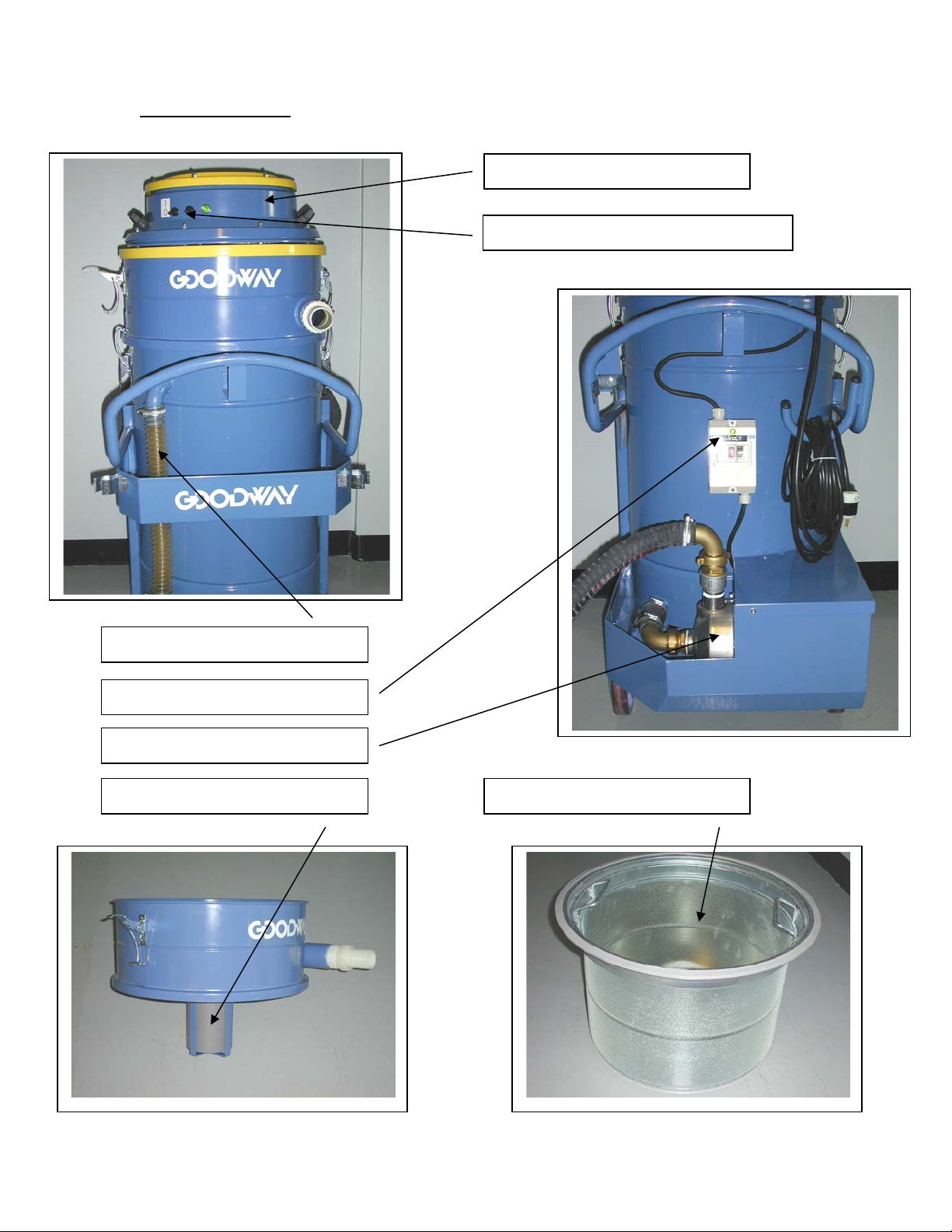

6. Attach the hose to the manifold and ensure all filters are in place

The unit is now ready for operation.

OPERATING INSTRUCTIONS

1. Switch on the vacuum motor by activating the vacuum motor switch. The DV-

CNC Model has two motor switches for each of its two motors. It is possible

to run both at the same time for added suction.

2. During recovery, regularly check the liquid level in the level indicator located

on the front of the unit. When the tank is full, the floating device stops the

air flow. The motor will continue to run, but suction ends.

3. Switch off the vacuum motors.

4. Open the valve on the handgun and activate the pump switch.

5. Pump the oil back into the machine tool or other container.

6. Switch the pump off when the unit is empty. Never run pump dry.