DV-M2 1/2013

GROUNDING INSTRUCTIONS

This vacuum must be grounded. If it should malfunction or break

down, grounding provides a path of least resistance for electric current

to reduce the risk of electric shock. This appliance is equipped with a

cord having an equipment-grounding conductor and grounding plug.

The plug must be inserted into an appropriate outlet that is properly

installed and grounded in accordance with all local codes and

ordinances.

WARNING – Improper connection of the equipment-grounding

conductor can result in a risk of electric shock. Check with a qualified

electrician or service person if you are in doubt as to whether the outlet

is properly grounded. Do not modify the plug provided with the

appliance – if it will not fit the outlet, have a proper outlet installed by a

qualified electrician.

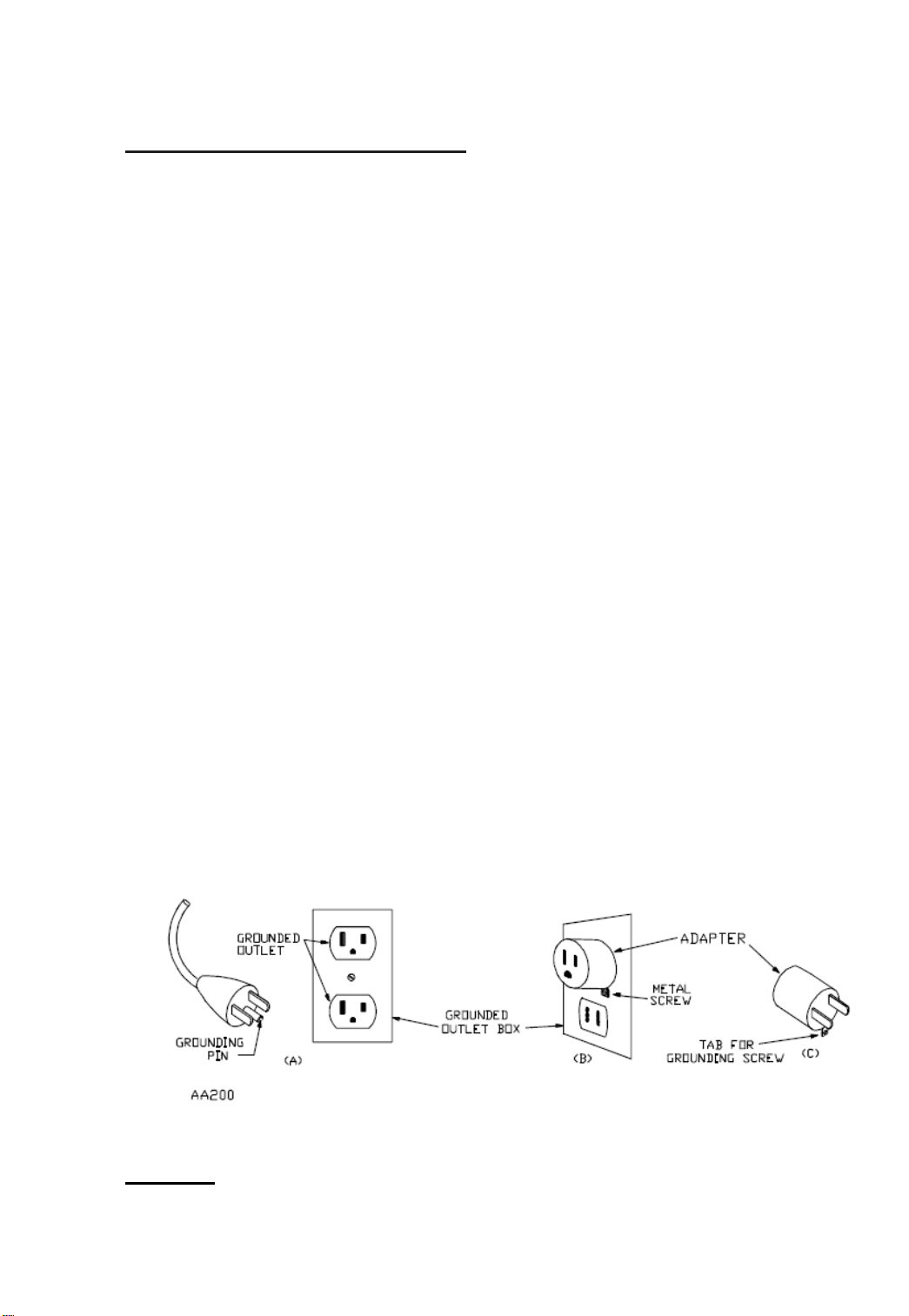

This appliance is for use on a nominal 120-volt circuit and has a

grounding attachment plug that looks like the plug illustrated in sketch

A below. A temporary adaptor that looks like the adaptor illustrated in

sketches B and C may be used to connect this plug to a two pole

receptacle as shown in sketch B if a properly grounded outlet is not

available. The temporary adaptor should be used only until a properly

grounded outlet (sketch A) can be installed by a qualified electrician.

The green colored rigid ear, lug or the like extending from the adaptor

must be connected to a permanent ground such as a properly

grounded outlet box cover. Whenever the adaptor is used, it must be

held in place by a metal screw.

NOTE: In Canada, the use of an adaptor is not permitted by the

Canadian Electrical Code.

SET-UP