Page 2of 19

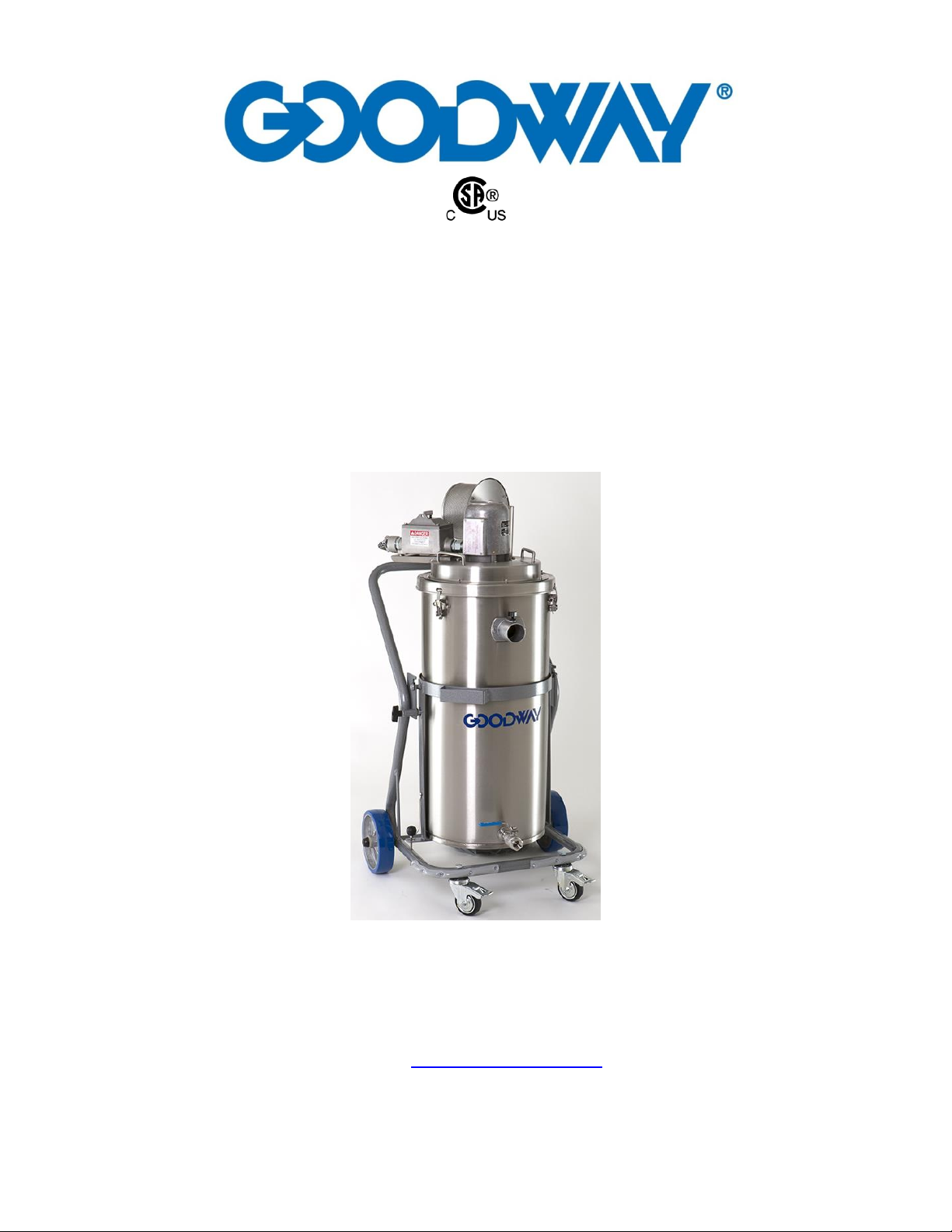

VAC-EX-120-25SS

1.0INSPECTION

Carefully unpack and inspect your Explosion Proof/Dust Ignition Proof vacuum cleaner

for shipping damage. Each vacuum cleaner is tested and thoroughly inspected before

being shipped; therefore, any damage is the responsibility of the delivering carrier,

who should be notified.

2.0APPLICATIONS

WARNING: A risk assessment has to be conducted by the user for the

recovery of dusts and liquids in hazardous areas. The recommendations in this

manual cannot, in any case, supplant the conclusions of a risk assessment.

VAC-EX-120-25SS explosion proof vacuum / dust ignition proof vacuum cleaner is

designed for Wet & Dry recovery and is certified for use in Class I - Group D, T3C and

Class II - Groups E, F & G Hazardous Locations as defined in the NFPA 70 (National

Electrical Code and Canadian Electrical code).

2.1. APPLICATIONS IN POTENTIALLY EXPLOSIVE ATMOSPHERES IN

PRESENCE OF SOLVENTS AND FLAMMABLE LIQUIDS

VAC-EX-120-25SS explosion proof vacuum / dust ignition proof vacuum cleaner is

certified for use in Class I - Group D, T3C Hazardous Locations as defined in the

NFPA 70 (National Electrical Code and Canadian Electrical code).

VAC-EX-120-25SS can be used in areas where solvents and flammable liquids are

present.

2.2. APPLICATIONS IN POTENTIALLY EXPLOSIVE ATMOSPHERES IN

PRESENCE OF COMBUSTIBLE DUST

VAC-EX-120-25SS explosion proof vacuum / dust ignition proof vacuum cleaner is

certified for use in Class II - Groups E, F & G Hazardous Locations as defined in the

NFPA 70 (National Electrical Code and Canadian Electrical code).

VAC-EX-120-25SS can be used to recover:

carbon black, charcoal, coal or coke dusts

flour, grain, wood, plastic and chemicals

And, based on the application, (See note below):

Explosive dusts (ex.: gun powder), combustible metal dusts, including

aluminum, magnesium, and their commercial alloys, or other combustible dusts

whose particle size, abrasiveness, and conductivity present an equivalent

hazard