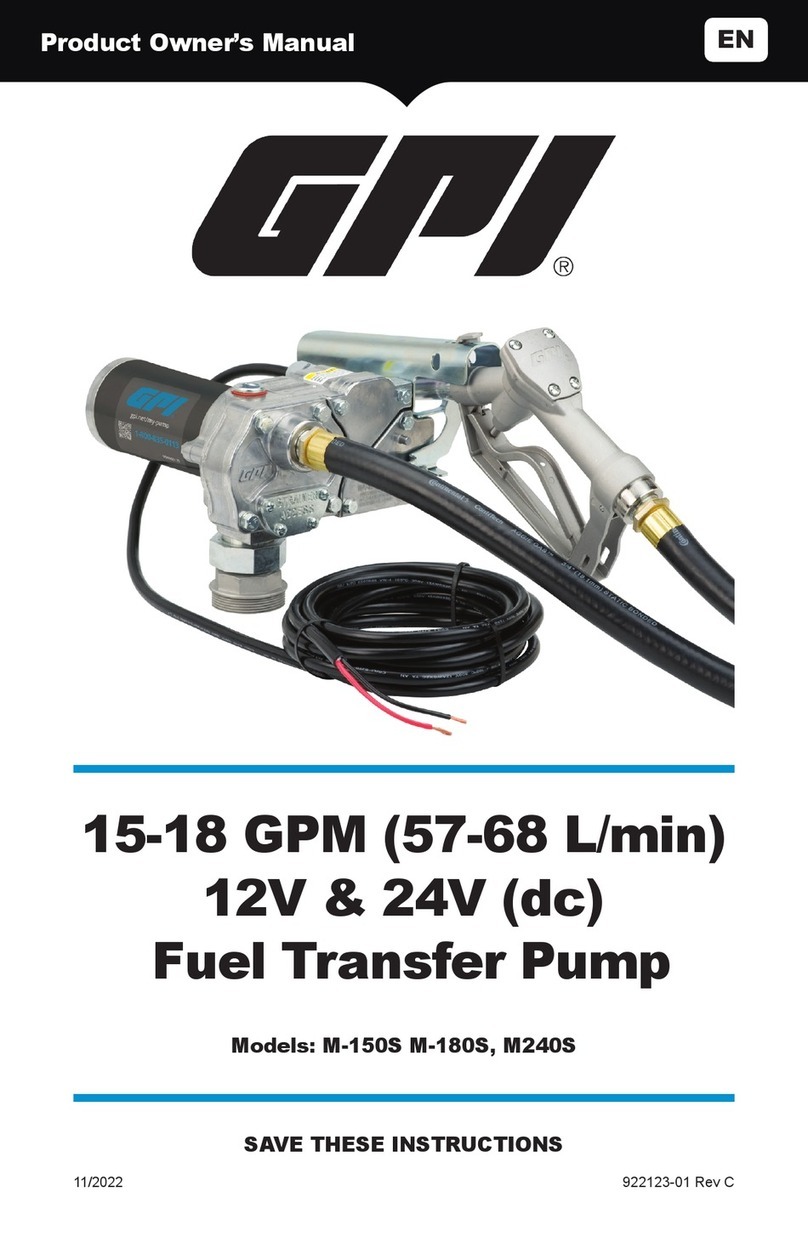

GENERAL INFORMATION

The purpose of this manual is to assist you in installing, op-

erating and maintaining your GPI Oil Pump. This pump is a

positive displacement, direct drive pump.

Observe all safety precautions concerning safe handling of

petroleum fluids. Do not use pump with low flash point fluids

(100°F or less).

To ensure safe operation, this pump must be properly grounded.

Care should be taken to ensure proper grounding during initial

installation and after any service or repair procedures. For your

safety, please take a moment to review the warnings below.

Observe precautions against electrical shock when operating

the system. Serious or fatal shock can result from operating

electrical equipment in damp or wet locations.

On 12-volt pumps, inspect external pump wiring regularly

to make sure it is correctly attached to the battery. To avoid

electrical shock, use extra care when connecting the pump

to power.

Avoid prolonged skin contact with petroleum fluids. Use

protective goggles, gloves and aprons in case of splashing

or spills. Change saturated clothing and wash skin promptly

with soap and water.

Observe precautions against electrical shock when servicing

the pump. Always disconnect power before repairing or ser-

vicing. Never apply electrical power to the system when any

of the coverplates are removed.

If using solvent to clean pump components or tank, observe

the solvent manufacturer’s recommendations for safe use

and disposal.

The 115-volt AC pump motors are equipped with thermal

overload protection. If overheated, the pump will shut itself

off. Turn off the pump if this occurs. See Motor Protector

Section for details.

Worn and damaged hoses or nozzles are potential safety

hazards and should be replaced.

Make sure all threaded connections are wrapped with three to

four turns of oil resistant thread tape or pipe thread sealant.

Make sure drums are properly secured to prevent tip over when

full or empty. All tanks must be properly vented.

Installing Pump to a Tank

GPI pumps have a 2 in. NPT connection that can be mounted

directly to a 2 in. female pipe thread on the tank.

1. Clean the tank interior of all dirt and foreign material.

2. Glue sections of suction pipe together and cut it to the

proper length that is required. Suction pipe should extend

2 to 3 inches above bottom of tank.

3. Screw suction pipe into inlet threads of pump base.

4. Insert the suction pipe through the tank bung. Screw pump

into tank bung to secure the pump to the tank. (Figure 1)

2

INSTALLATION

Both the 12-volt DC and the 115-volt AC pump are compat-

ible with motor oil, gear oil, hydraulic oil, antifreeze (not to

exceed 50% water), ATF and waste oil. Do not use this pump

for dispensing any fluids other than those for which it was

designed. To do so may damage pump components and will

void the warranty.

Do not use the GPI Oil pump with water, acids, brake fluid or

windshield washer fluid.

If in doubt about compatibility of a specific fluid, contact the

supplier of the fluid to check for chemical compatibility with:

• Aluminum

• Brass

• Nitrile Rubber

• Stainless Steel

• Steel

• Zinc Plated Steel

Do not leave the system running without fluids. “Dry running”

can damage the pump.

Do not pump the tank completely dry, as contaminants from

the bottom of the tank may enter the pump.

The following safety alert symbols are used

in this manual.

DANGER indicates a haz-

ardous situation which, if

not avoided, will result in

death or serious injury.

WARNING indicates a haz-

ardous situation which, if

not avoided, could result in

death or serious injury.

CAUTION indicates a haz-

ardous situation which, if

not avoided, may result in

minor or moderate injury.

It is your responsibility to:

• know and follow applicable national, state, and local safety

codes pertaining to installing and operating electrical equip-

ment for use with petroleum fluids.

• insure that all equipment operators have access to adequate

instructions concerning safe operating and maintenance

procedures.

SAFETY INSTRUCTIONS

DANGER

WARNING

CAUTION