23A6338F

Contents

Related Manuals . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

CGM Software . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

EFR and PLC Connection . . . . . . . . . . . . . . . . . . 5

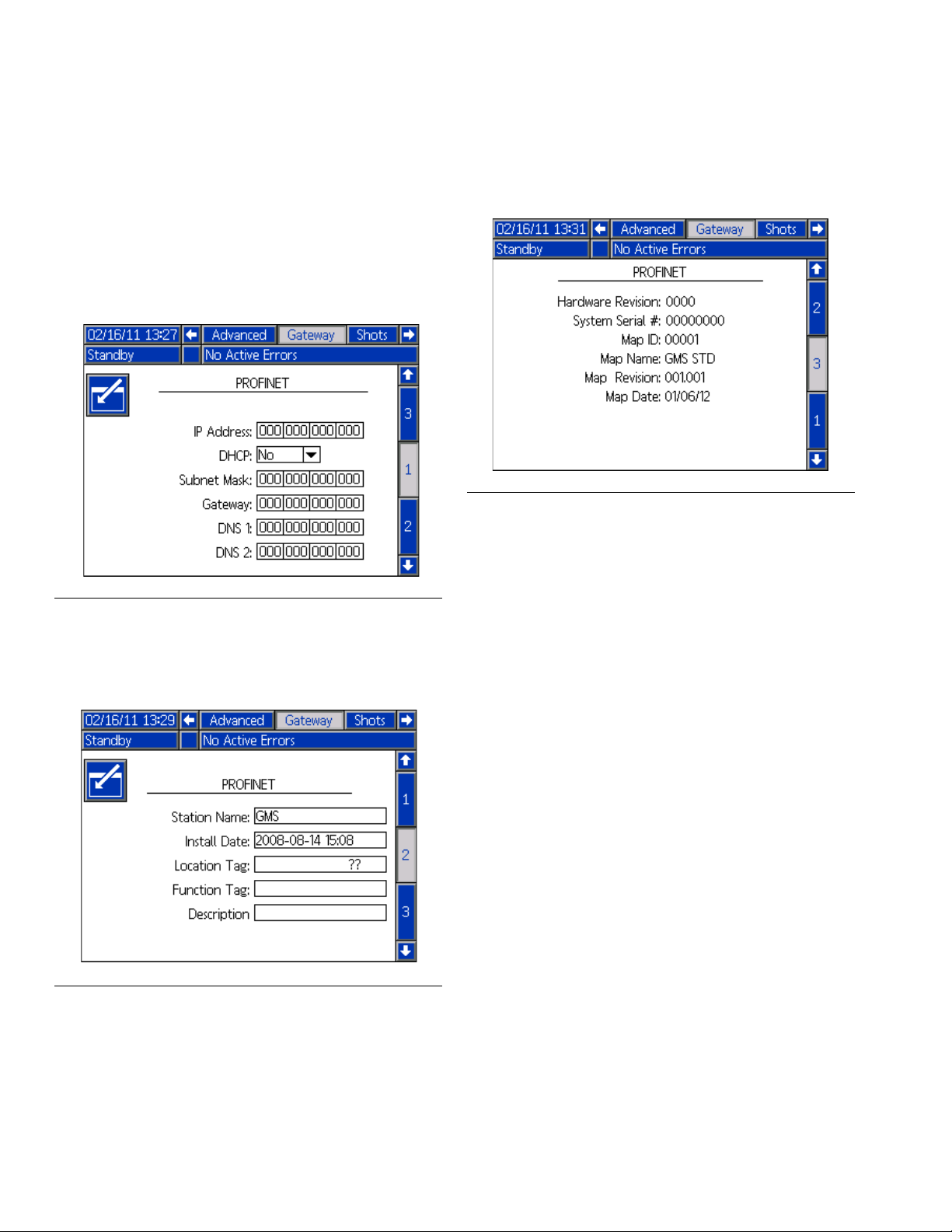

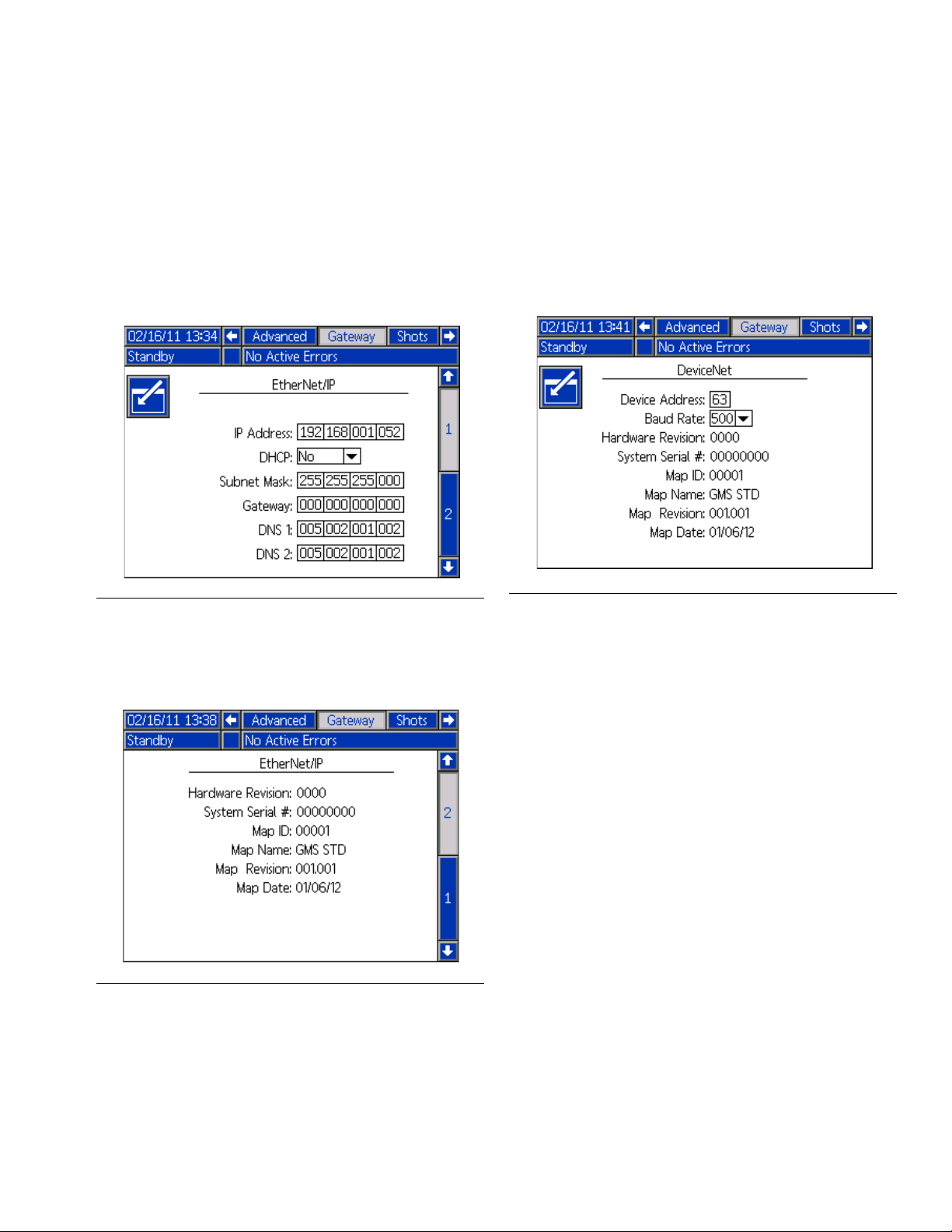

Gateway Screens . . . . . . . . . . . . . . . . . . . . . . . . 5

Available Internal Data . . . . . . . . . . . . . . . . . . . . . . 8

Automation Inputs (signals from EFR system to

PLC) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Automation Outputs (signals from PLC to EFR

system) . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

CGM General Timing Diagrams . . . . . . . . . . . . 13

Appendix A - I/O Signal Descriptions . . . . . . . . . 22

Automation Inputs (signals from EFR system to

PLC) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Automation Outputs (signals from PLC to EFR

System) . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Appendix B - Data Exchanged . . . . . . . . . . . . . . . 27

EFR Data Exchange Elements . . . . . . . . . . . . . 28

Appendix C - Sequence Step Data Exchange . . . 36

EFR Sequence Step Data Exchange Elements 37

Appendix D - Error Number Requiring

Acknowledgment . . . . . . . . . . . . . . . . . . . . . . 38

Graco Standard Warranty . . . . . . . . . . . . . . . . . . . 42

Graco Information . . . . . . . . . . . . . . . . . . . . . . . . . 42

Related Manuals

Models

Overview

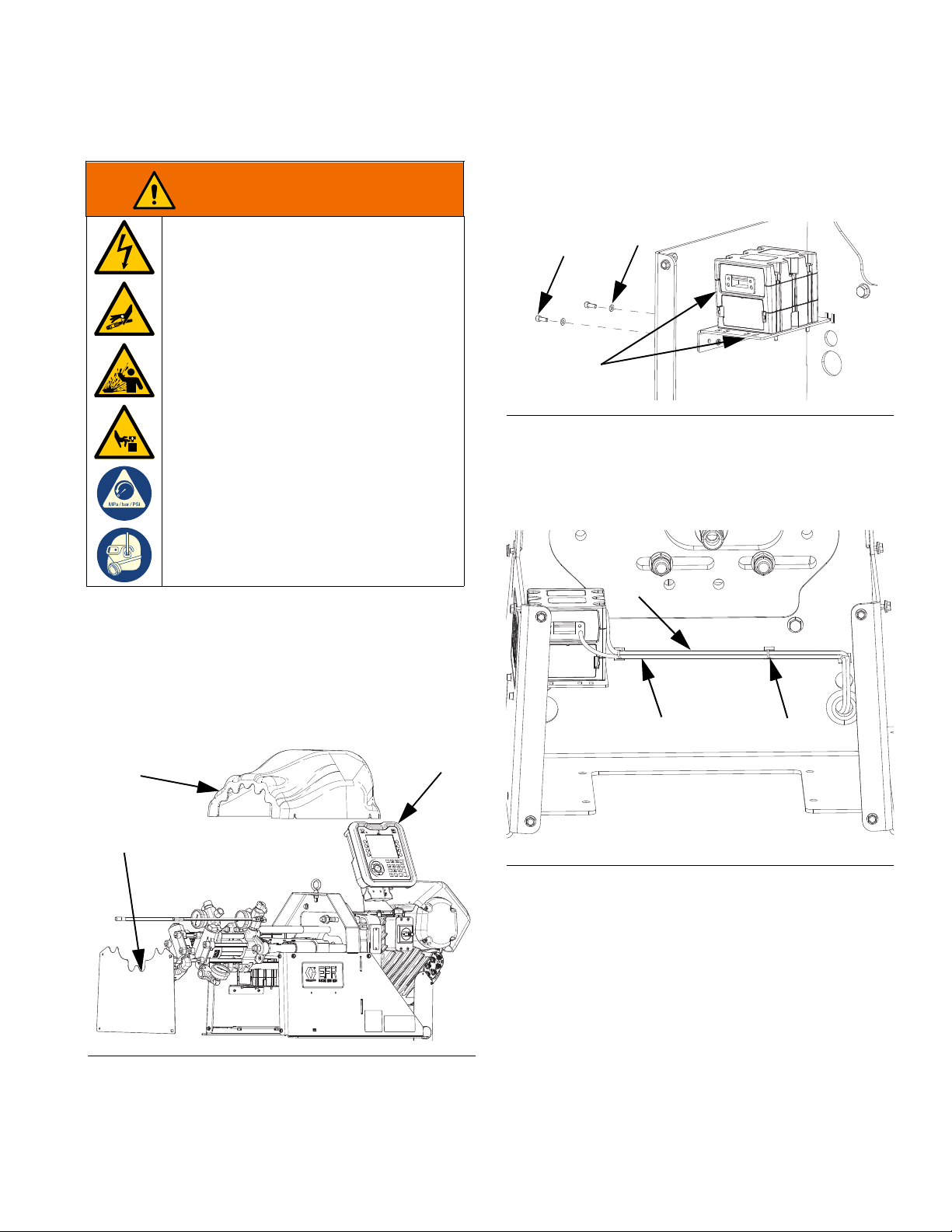

The Communications Gateway Module (CGM) provides

a control link between the Electric Fixed Ratio (EFR)

system and a selected fieldbus. This provides the

means for report monitoring and control by external

automation systems.

NOTE: Visit help.graco.com for updated EFR software,

maps, and the network configuration files listed below.

• EDS file: DeviceNet or Ethernet/IP fieldbus networks

• GSD file: PROFIBUS fieldbus networks

• GSDML: PROFINET fieldbus networks

• ACD file: DeviceNet or Ethernet/IP fieldbus networks

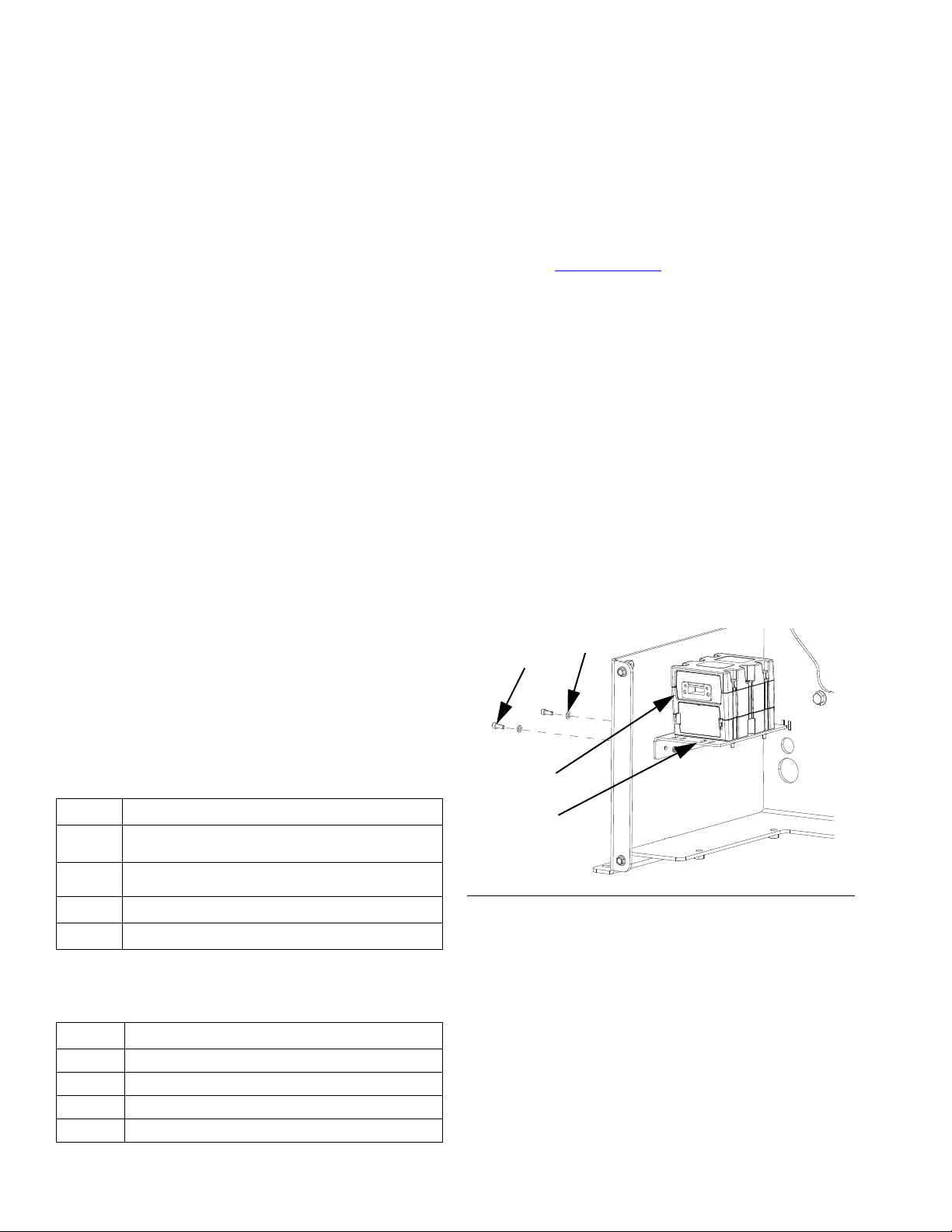

The following components are included in the CGM

Installation Kit.

CGM Software

The following software is must be installed on the CGM

module to work properly with the EFR CGM map

19A796.

• 17P796, version 3.01.004

Manual Description

312864 Communications Gateway Module, Instructions -

Parts

3A6165 Electric Fixed Ratio Proportioner, Setup -

Operation

406987 GCA CAN Cables, Reference

3A8115 Voltex

™

Dynamic Mix Valve, Instructions - Parts

Part Description

25B127 DeviceNet CGM Kit

26A700 EtherNet/IP CGM Kit

26A701 PROFIBUS CGM Kit

26A702 PROFINET CGM Kit

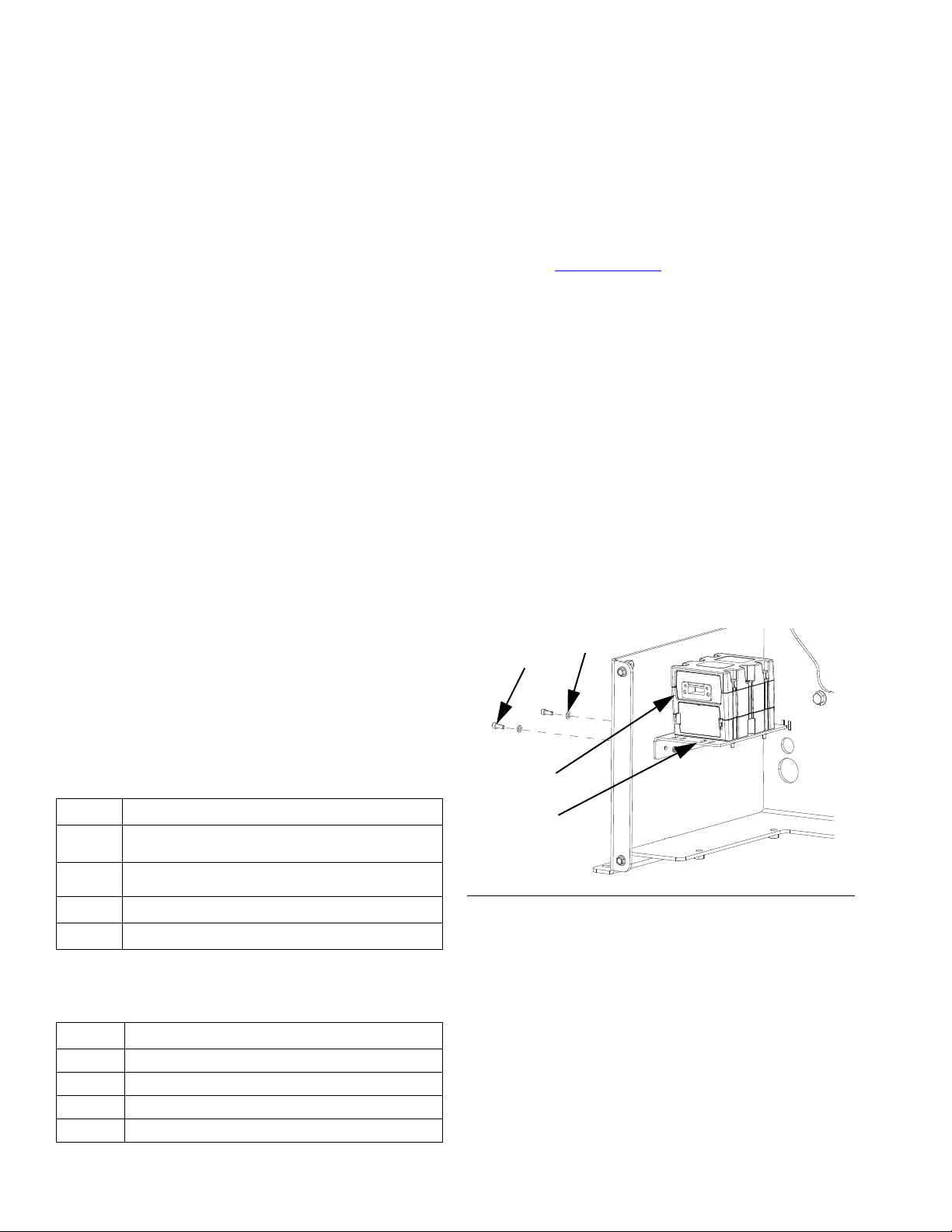

Ref. Description Qty.

ACGMKit 1

AA Gateway Module 1

AB Mounting Bracket 1

B Screw, #10-32 x .50 2

C Washer, #10, Nylon 2

D Communication Cable (not shown) 1

F

IG

. 1