Service

8 308048N

8. Remove the cap screws (12), the drip pan (16), the

drip cover (18), and machine screw (20) before

loosening the tie rod nuts. Then remove the four tie

rod nuts (19). Loosen the nuts (B) on the hydraulic

tube (4) and loosen the tie rods (57).

9. Remove the motor from the vise and lay it in a pan.

10. Remove one detent assembly: retaining plug (39),

o-ring (41), spring (40), ball guide (42) and ball (43).

If the ball or other parts stick in the upper housing

(53), turn the motor over and tap lightly. Do not

allow the parts to fall into the motor. Repeat the

procedure for the other detent assembly.

11. Remove the tie rods (57), but do not remove the

crown nuts (44).

12. Remove the socket screws (51) and the end cap

(47). Pull the stop plug (48) from the upper housing

(53).

13. Unscrew the top and bottom compression nuts (B)

on the hydraulic tube (4). Rotate the upper housing

(53) and remove the tube, being careful not to

damage the flare (A). Allow the oil to drain from the

motor into the pan.

14. Rock the upper housing (53) to work it free and lift it

about 3 inches off the cylinder (29). The cylinder

can stay in the lower housing (25).

15. Hold the trip rod (31) with an adjustable wrench on

the flats of the rod, and remove the top hex nut (46)

from the trip rod.

16. Remove the upper housing (53).

17. Remove the trip rod guides (37), compression

springs (45) and valve spool (38) from the upper

housing. Inspect the bearing inside of the guide (35)

in place. If bearing is damaged replace item 35.

NOTE: Inspect the trip rod (31) above the shoulder for

damage. There must be no reduction in diameter.

Replace if necessary.

18. Pull the trip rod and piston from the lower housing

(25) and cylinder (29). Place the piston flats (30a) in

a vise; tighten the vise on the flats of the piston.

Remove retaining ring (30c). Use a face spanner to

remove the retainer (30b). Remove the trip rod (31)

from the piston (30a).

19. Remove the trip rod locknut (27) and piston stop

(28). If the piston is replaced, remove the spring (26)

to use in the new piston.

20. Remove the bearing (23), packings (24), and o-ring

(21).

Reassembly (Refer to pg. 11)

1. Install the bearing (23*) in the lower housing (25).

Lubricate the seals (24*) with hydraulic oil. Install them

in the lower housing (25) with the lips facing up toward

the top of the motor.

2. Install the o-ring (21*) onto the lower housing (25).

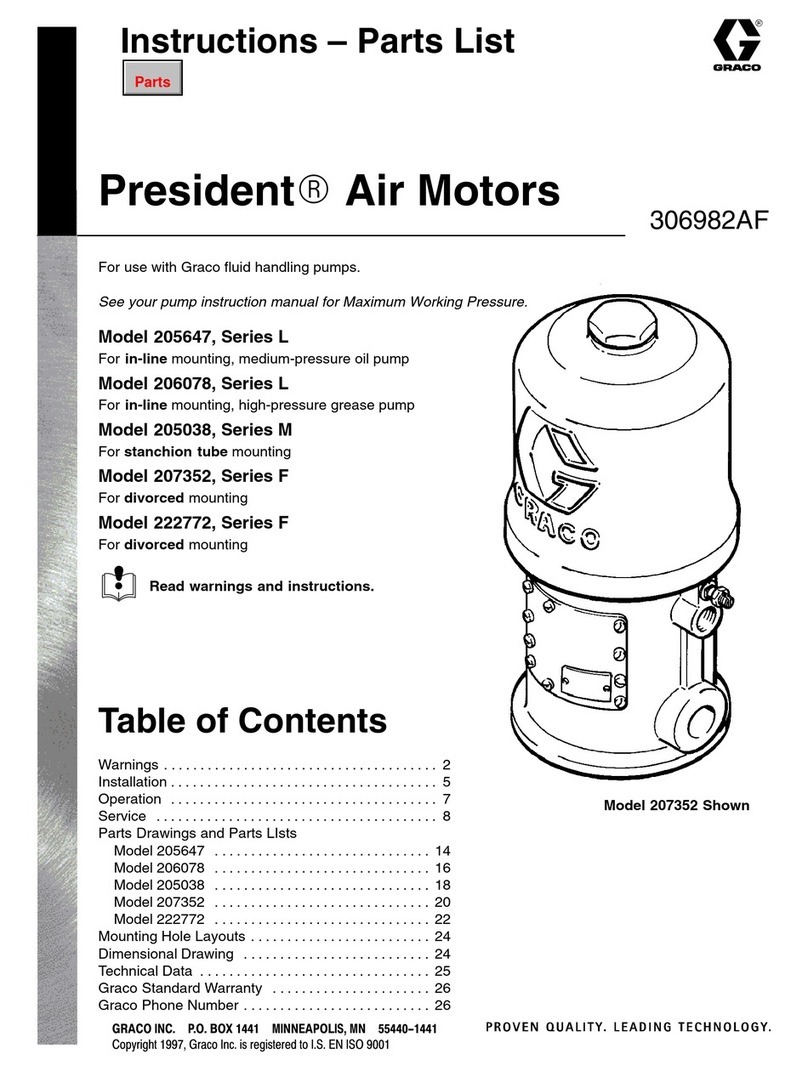

3. Place the piston flats in a vise. Install the spring (26)

inside the piston (30a). The compression rings (32*)

must be positioned with the joints about 180°

opposed.

4. Install the piston stop (28) and locknut (27) on the trip

rod. Torque the nut to 117--123 in-lb (13.2-13.9 Nm).

Slide the trip rod (31) into the piston (30a). Apply

thread sealant to the retainer (30b) threads.

With the piston flats in a vise, tighten retainer until it is

slightly below the retaining ring groove. Install

retaining ring (30c). This is important to prevent the

retainer from backing out during operation and

damaging the motor.

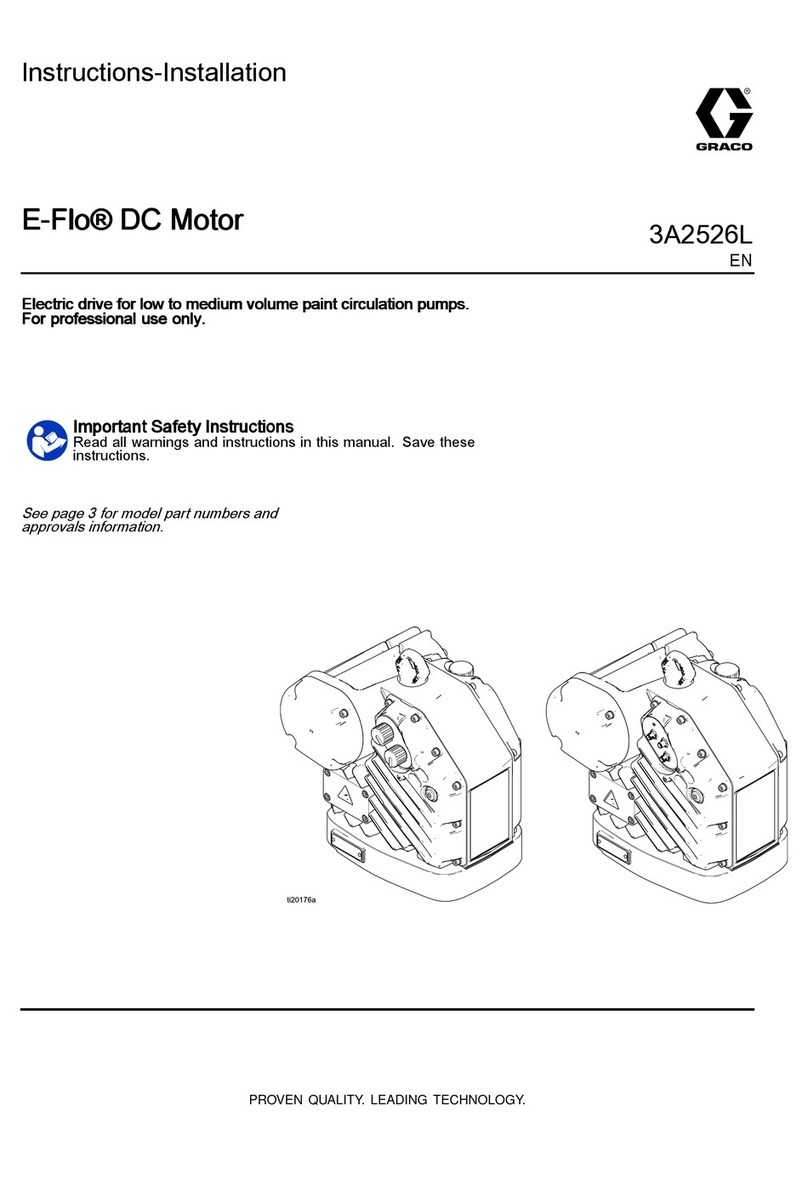

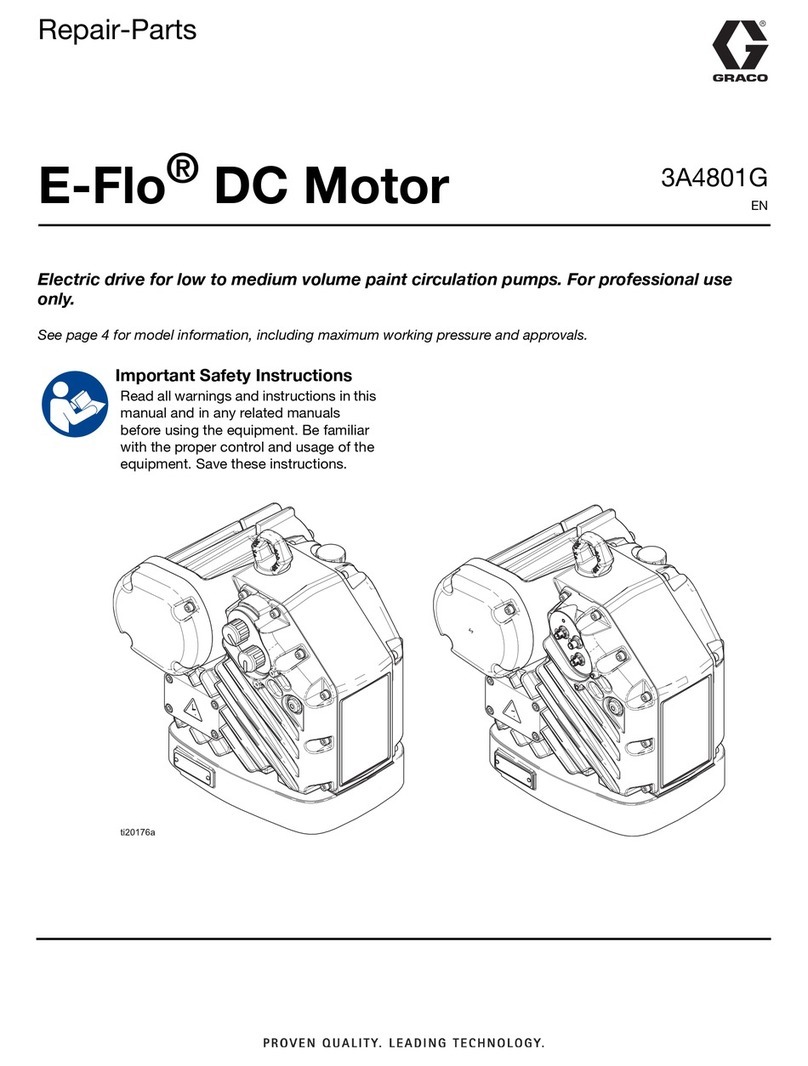

FIG. 3 ___________________________________________

NOTE: Graco recommends replacing piston (30a),

retainer (30b), and retaining ring (30c) together in kits

appropriate to motor configurations. Retainer (30c) can

be used on old pistons without retaining groove, but

must be threaded in completely.

NOTE: Set base (2) on workbench during reassembly.

5. Install the o-ring (33*) onto the cylinder (29). Install the

cylinder (29) into the lower housing (25).

6. Install the trip rod and piston into the cylinder (29) and

lower housing (25) so the piston is recessed at least 1

inch (25 mm) from the top of the cylinder.

NOTICE

With the tie rods removed, the assembly may separate

at the joints between the cylinder (29) and the upper

and lower housings (53 and 25). Hold motor and

housings securely when removing parts to avoid

premature separation of large parts and possible

damage to parts from falls.

30b

30a

30b

30a

30c

New Piston Old Piston